What is Global Warehousing and Logistics Sorting Robot Market?

The Global Warehousing and Logistics Sorting Robot Market refers to the industry focused on the development, production, and deployment of robots designed to automate various tasks within warehouses and logistics centers. These robots are engineered to enhance efficiency, accuracy, and speed in sorting, picking, and transporting goods. The market encompasses a wide range of robotic solutions, including picking robots, autonomous navigation robots, and other specialized robots tailored for specific tasks. The adoption of these robots is driven by the increasing demand for faster and more reliable order fulfillment, the need to reduce labor costs, and the growing complexity of supply chain operations. As e-commerce continues to expand and consumer expectations for rapid delivery rise, the role of warehousing and logistics sorting robots becomes increasingly critical. These robots not only streamline operations but also help businesses maintain competitiveness in a fast-paced market. The market is characterized by continuous innovation, with advancements in artificial intelligence, machine learning, and sensor technologies contributing to the development of more sophisticated and capable robotic systems.

Picking Robot, Autonomous Navigation Robot, Others in the Global Warehousing and Logistics Sorting Robot Market:

Picking robots, autonomous navigation robots, and other specialized robots play pivotal roles in the Global Warehousing and Logistics Sorting Robot Market. Picking robots are designed to automate the process of selecting and retrieving items from storage locations. These robots are equipped with advanced vision systems and grippers that enable them to identify, grasp, and move items with precision. They are particularly useful in environments where a high volume of small, varied items need to be picked and packed quickly. By automating the picking process, these robots significantly reduce the time and labor required for order fulfillment, thereby increasing overall efficiency and accuracy. Autonomous navigation robots, on the other hand, are designed to move goods within a warehouse or logistics center without human intervention. These robots use a combination of sensors, cameras, and mapping technologies to navigate complex environments, avoid obstacles, and transport items from one location to another. They can be programmed to follow specific routes or adapt to dynamic changes in the environment, making them highly versatile and efficient. Autonomous navigation robots are particularly beneficial in large warehouses where the distance between storage and packing areas can be substantial. By automating the transportation of goods, these robots help reduce the physical strain on human workers and minimize the risk of errors and accidents. In addition to picking and autonomous navigation robots, the market also includes a variety of other specialized robots designed for specific tasks. For example, sorting robots are used to categorize and organize items based on predefined criteria. These robots can quickly and accurately sort items by size, weight, or destination, making them invaluable in high-volume logistics operations. Another example is palletizing robots, which are used to stack and arrange goods on pallets for storage or shipment. These robots are equipped with advanced algorithms that enable them to optimize the arrangement of items, ensuring stability and maximizing space utilization. The integration of these different types of robots within a single warehouse or logistics center can lead to significant improvements in operational efficiency. For instance, a picking robot can retrieve items from storage and hand them off to an autonomous navigation robot, which then transports the items to a sorting robot for categorization. This seamless collaboration between different robotic systems helps streamline the entire order fulfillment process, from picking and packing to sorting and shipping. Moreover, the use of robots in warehousing and logistics also contributes to improved workplace safety. By automating repetitive and physically demanding tasks, robots help reduce the risk of injuries and accidents among human workers. This not only enhances worker well-being but also leads to lower healthcare and insurance costs for businesses. In conclusion, the Global Warehousing and Logistics Sorting Robot Market encompasses a wide range of robotic solutions designed to automate various tasks within warehouses and logistics centers. Picking robots, autonomous navigation robots, and other specialized robots each play a crucial role in enhancing efficiency, accuracy, and safety in these environments. As technology continues to advance, the capabilities of these robots are expected to grow, further driving their adoption and impact on the industry.

Manufacturing, Retail Industry, Medicine, Food in the Global Warehousing and Logistics Sorting Robot Market:

The usage of Global Warehousing and Logistics Sorting Robots spans across various industries, including manufacturing, retail, medicine, and food. In the manufacturing sector, these robots are employed to streamline the production process by automating the movement of raw materials, components, and finished products. Picking robots can be used to retrieve parts from storage and deliver them to assembly lines, while autonomous navigation robots transport goods between different stages of production. This automation not only speeds up the manufacturing process but also reduces the risk of errors and improves overall product quality. Additionally, the use of robots in manufacturing helps optimize inventory management by ensuring that materials are always available when needed, thereby minimizing downtime and enhancing productivity. In the retail industry, warehousing and logistics sorting robots play a crucial role in managing the high volume of goods that need to be stored, picked, packed, and shipped to customers. With the rise of e-commerce, retailers face increasing pressure to fulfill orders quickly and accurately. Picking robots help automate the selection of items from storage, while sorting robots categorize and organize these items for shipment. Autonomous navigation robots transport goods within the warehouse, ensuring that items are delivered to the right location at the right time. This automation not only speeds up the order fulfillment process but also enhances accuracy, reducing the likelihood of errors and returns. As a result, retailers can provide better service to their customers and maintain a competitive edge in the market. In the field of medicine, warehousing and logistics sorting robots are used to manage the storage and distribution of medical supplies, pharmaceuticals, and equipment. Picking robots can be programmed to retrieve specific items from storage, ensuring that the right products are selected for each order. Autonomous navigation robots transport these items within the warehouse, while sorting robots categorize and organize them for shipment. This automation helps ensure that medical supplies are delivered quickly and accurately, which is critical in healthcare settings where timely access to medications and equipment can impact patient outcomes. Additionally, the use of robots in medical warehousing helps maintain the integrity of sensitive products by minimizing human handling and reducing the risk of contamination. In the food industry, warehousing and logistics sorting robots are used to manage the storage and distribution of perishable goods. Picking robots can quickly retrieve items from storage, while autonomous navigation robots transport these items to sorting robots for categorization. This automation helps ensure that perishable goods are handled efficiently and delivered to their destination in a timely manner, reducing the risk of spoilage and waste. Additionally, the use of robots in food warehousing helps maintain hygiene standards by minimizing human contact with food products. This is particularly important in the context of food safety regulations, where strict guidelines must be followed to prevent contamination and ensure the quality of food products. In conclusion, the usage of Global Warehousing and Logistics Sorting Robots spans across various industries, including manufacturing, retail, medicine, and food. In each of these sectors, robots play a crucial role in automating tasks, enhancing efficiency, and improving accuracy. By streamlining operations and reducing the risk of errors, these robots help businesses meet the demands of their customers and maintain a competitive edge in the market. As technology continues to advance, the capabilities of these robots are expected to grow, further driving their adoption and impact across different industries.

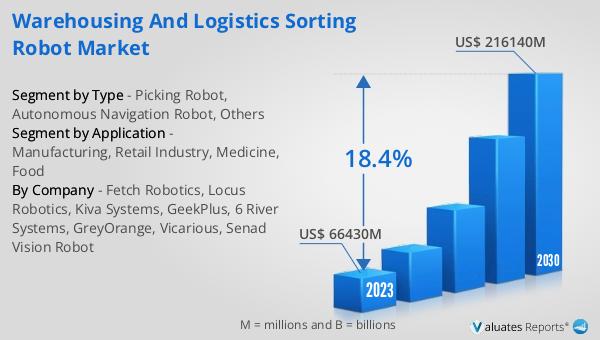

Global Warehousing and Logistics Sorting Robot Market Outlook:

The global Warehousing and Logistics Sorting Robot market was valued at US$ 66,430 million in 2023 and is anticipated to reach US$ 216,140 million by 2030, witnessing a CAGR of 18.4% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for automation in warehousing and logistics operations. As businesses strive to enhance efficiency, reduce labor costs, and meet the rising expectations for rapid order fulfillment, the adoption of sorting robots is expected to accelerate. These robots, equipped with advanced technologies such as artificial intelligence and machine learning, are capable of performing complex tasks with high precision and speed. The market's expansion is also driven by the continuous innovation in robotic systems, which are becoming more sophisticated and capable of handling a wider range of tasks. As a result, the global Warehousing and Logistics Sorting Robot market is poised for substantial growth, offering numerous opportunities for businesses to optimize their operations and stay competitive in a fast-paced market.

| Report Metric | Details |

| Report Name | Warehousing and Logistics Sorting Robot Market |

| Accounted market size in 2023 | US$ 66430 million |

| Forecasted market size in 2030 | US$ 216140 million |

| CAGR | 18.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fetch Robotics, Locus Robotics, Kiva Systems, GeekPlus, 6 River Systems, GreyOrange, Vicarious, Senad Vision Robot |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |