What is Global Ultra-fine Grain Isotropic Graphite Market?

The Global Ultra-fine Grain Isotropic Graphite Market refers to the worldwide industry focused on the production, distribution, and utilization of ultra-fine grain isotropic graphite. This type of graphite is characterized by its uniform grain structure and extremely fine particle size, which provides superior mechanical, thermal, and electrical properties compared to conventional graphite. Ultra-fine grain isotropic graphite is highly valued in various high-tech applications due to its excellent strength, high purity, and resistance to thermal shock and oxidation. Industries such as semiconductor manufacturing, photovoltaic cell production, electrical discharge machining (EDM), and metallurgy rely heavily on this material for its performance and reliability. The market encompasses a range of activities including research and development, manufacturing, quality control, and sales, with key players operating globally to meet the increasing demand for advanced materials in cutting-edge technologies. The market dynamics are influenced by factors such as technological advancements, industrial growth, and the need for high-performance materials in various applications.

Particle Size ≤ 5 µm, 5 µm < Particle Size ≤10, 10 µm < Particle Size ≤15, 15 µm < Particle Size ≤20 in the Global Ultra-fine Grain Isotropic Graphite Market:

In the Global Ultra-fine Grain Isotropic Graphite Market, particle size plays a crucial role in determining the material's properties and suitability for different applications. Particle sizes are typically categorized into four main ranges: ≤ 5 µm, 5 µm < Particle Size ≤ 10 µm, 10 µm < Particle Size ≤ 15 µm, and 15 µm < Particle Size ≤ 20 µm. Each range offers distinct characteristics that make the graphite suitable for specific uses. For instance, ultra-fine particles (≤ 5 µm) provide exceptional surface finish and precision, making them ideal for high-precision applications such as semiconductor manufacturing and microelectronics. These particles ensure minimal defects and high-quality outputs, which are critical in these industries. The next range, 5 µm < Particle Size ≤ 10 µm, balances fine surface finish with mechanical strength, making it suitable for applications like electrical discharge machining (EDM) where both precision and durability are required. Graphite in this range is also used in the production of photovoltaic cells, where it contributes to the efficiency and longevity of solar panels. Moving to the 10 µm < Particle Size ≤ 15 µm range, the graphite offers a good compromise between fine grain structure and cost-effectiveness. This makes it a popular choice in foundry and metallurgy applications, where it is used for casting and molding processes that require high thermal conductivity and resistance to thermal shock. Finally, the 15 µm < Particle Size ≤ 20 µm range provides robust mechanical properties and is often used in defense and heavy industrial applications. This range of particle size ensures the material can withstand harsh conditions and high-stress environments, making it suitable for military equipment and large-scale industrial machinery. Each particle size range in the Global Ultra-fine Grain Isotropic Graphite Market is tailored to meet the specific needs of various industries, ensuring optimal performance and reliability in their respective applications.

Photovoltaic, Semiconductor, Electrical Discharge Machining, Foundry, Metallurgy, Defense, Others in the Global Ultra-fine Grain Isotropic Graphite Market:

The Global Ultra-fine Grain Isotropic Graphite Market finds extensive usage across several high-tech and industrial sectors due to its superior properties. In the photovoltaic industry, ultra-fine grain isotropic graphite is used in the production of solar cells. Its high purity and thermal stability make it an ideal material for the manufacturing processes, ensuring efficient energy conversion and long-lasting solar panels. In the semiconductor industry, this type of graphite is crucial for the production of semiconductor wafers and components. Its excellent electrical conductivity and resistance to thermal shock make it indispensable for creating high-performance electronic devices. Electrical Discharge Machining (EDM) is another area where ultra-fine grain isotropic graphite is extensively used. The material's ability to withstand high temperatures and its fine grain structure allow for precise and efficient machining of complex shapes and hard materials. In the foundry and metallurgy sectors, ultra-fine grain isotropic graphite is used for casting and molding processes. Its high thermal conductivity and resistance to thermal shock ensure high-quality castings and molds, which are essential for producing durable metal components. The defense industry also benefits from the use of this advanced material. Its robust mechanical properties and resistance to harsh conditions make it suitable for military applications, including the production of high-strength components and equipment. Other industries, such as aerospace and automotive, also utilize ultra-fine grain isotropic graphite for its superior performance characteristics. The material's versatility and reliability make it a valuable asset in various high-tech and industrial applications, driving its demand in the global market.

Global Ultra-fine Grain Isotropic Graphite Market Outlook:

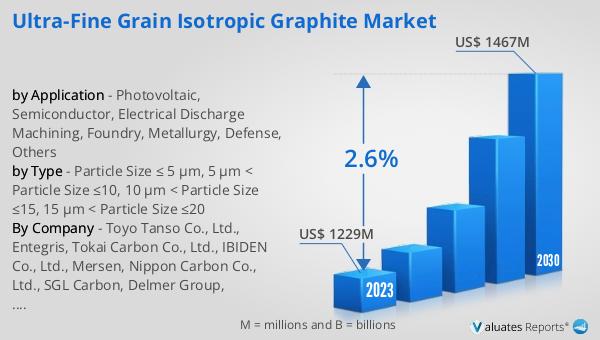

The global Ultrafine Grain Isotropic Graphite market was valued at US$ 1229 million in 2023 and is anticipated to reach US$ 1467 million by 2030, witnessing a CAGR of 2.6% during the forecast period 2024-2030. This market outlook highlights the steady growth and increasing demand for ultra-fine grain isotropic graphite across various industries. The projected growth reflects the material's critical role in high-tech applications and its superior properties that meet the stringent requirements of advanced manufacturing processes. The market's expansion is driven by the continuous advancements in technology and the growing need for high-performance materials in sectors such as semiconductor manufacturing, photovoltaic cell production, and electrical discharge machining. The increasing adoption of ultra-fine grain isotropic graphite in these industries underscores its importance in achieving high precision, efficiency, and reliability in production processes. As the market continues to grow, key players are expected to focus on innovation and quality improvement to meet the evolving demands of their customers. The steady CAGR of 2.6% indicates a positive outlook for the global Ultrafine Grain Isotropic Graphite market, with significant opportunities for growth and development in the coming years.

| Report Metric | Details |

| Report Name | Ultra-fine Grain Isotropic Graphite Market |

| Accounted market size in 2023 | US$ 1229 million |

| Forecasted market size in 2030 | US$ 1467 million |

| CAGR | 2.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toyo Tanso Co., Ltd., Entegris, Tokai Carbon Co., Ltd., IBIDEN Co., Ltd., Mersen, Nippon Carbon Co., Ltd., SGL Carbon, Delmer Group, GrafTech International Ltd., LiaoNing DaHua Glory Speclal Graphite Co., Ltd., WuXing New Material Technology Co., Ltd., Chengdu Carbon Co.,Ltd., Sichuan Guanghan Shida Carbon Co., Ltd., Graphite India Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |