What is Global Submerged Arc Wires and Fluxes Market?

The Global Submerged Arc Wires and Fluxes Market refers to the worldwide industry involved in the production, distribution, and utilization of submerged arc welding (SAW) wires and fluxes. These materials are essential components in the submerged arc welding process, a method widely used for its efficiency and high-quality welds. The market encompasses various types of wires and fluxes, each designed for specific applications and welding conditions. The demand for these products is driven by their extensive use in industries such as shipbuilding, construction, and manufacturing, where strong, durable welds are crucial. The market's growth is influenced by factors such as technological advancements, increasing industrialization, and the need for high-performance welding solutions. As industries continue to expand and modernize, the Global Submerged Arc Wires and Fluxes Market is expected to see significant growth, driven by the ongoing demand for reliable and efficient welding materials.

Submerged Arc Wire, Submerged Arc Flux in the Global Submerged Arc Wires and Fluxes Market:

Submerged Arc Wire and Submerged Arc Flux are integral components of the submerged arc welding (SAW) process, which is renowned for its efficiency and ability to produce high-quality welds. Submerged Arc Wire, typically made from materials like carbon steel, stainless steel, or alloy steel, serves as the filler material that melts and joins the workpieces. These wires come in various diameters and compositions to suit different welding requirements and applications. On the other hand, Submerged Arc Flux is a granular material that covers the welding area, protecting the molten weld pool from atmospheric contamination and stabilizing the arc. Fluxes can be fused, bonded, or agglomerated, each type offering distinct advantages in terms of slag removal, weld bead appearance, and mechanical properties. The combination of these wires and fluxes in the SAW process results in deep penetration welds with minimal spatter and high deposition rates, making it ideal for heavy-duty applications. The Global Submerged Arc Wires and Fluxes Market caters to a wide range of industries, including shipbuilding, construction, and manufacturing, where the demand for robust and reliable welding solutions is paramount. As industries continue to evolve and seek more efficient production methods, the market for these essential welding materials is poised for sustained growth.

Automobile, Shipbuilding, Marine Engineering, Pressure Vessel, Construction Bridge, Engineering Machinery, Pipeline Storage Tank in the Global Submerged Arc Wires and Fluxes Market:

The usage of Global Submerged Arc Wires and Fluxes Market spans several critical industries, each benefiting from the unique advantages of the submerged arc welding (SAW) process. In the automobile industry, SAW is employed for welding heavy-duty components such as chassis and frames, where strong, durable welds are essential for vehicle safety and performance. The shipbuilding industry relies heavily on SAW for constructing large vessels, as the process ensures deep penetration and high-quality welds that can withstand harsh marine environments. Marine engineering also benefits from SAW, particularly in the fabrication of offshore structures and underwater pipelines, where reliability and strength are crucial. In the pressure vessel industry, SAW is used to weld thick-walled containers that store gases or liquids under high pressure, ensuring leak-proof and robust joints. The construction of bridges and other infrastructure projects utilizes SAW for its ability to produce long, continuous welds with minimal defects, enhancing structural integrity. Engineering machinery, such as cranes and heavy equipment, also relies on SAW for assembling large, load-bearing components. Lastly, the pipeline and storage tank industry uses SAW for welding long sections of pipes and large storage tanks, where the process's efficiency and high deposition rates are particularly advantageous. Overall, the Global Submerged Arc Wires and Fluxes Market plays a vital role in these industries, providing the materials needed for high-performance and reliable welding solutions.

Global Submerged Arc Wires and Fluxes Market Outlook:

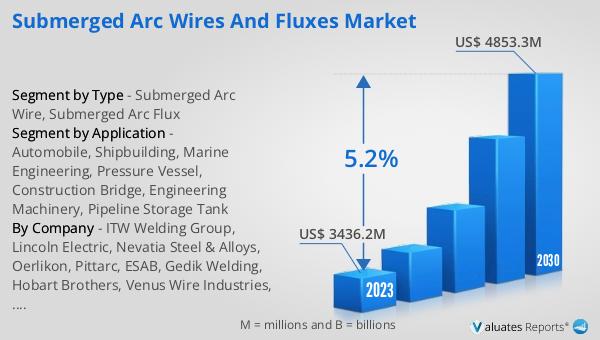

The global Submerged Arc Wires and Fluxes market was valued at US$ 3436.2 million in 2023 and is anticipated to reach US$ 4853.3 million by 2030, witnessing a CAGR of 5.2% during the forecast period 2024-2030. This market growth reflects the increasing demand for high-quality welding materials across various industries. The efficiency and reliability of the submerged arc welding process make it a preferred choice for applications requiring strong, durable welds. As industries such as shipbuilding, construction, and manufacturing continue to expand and modernize, the need for advanced welding solutions is expected to drive the market's growth. The projected increase in market value underscores the importance of submerged arc wires and fluxes in meeting the evolving demands of these industries. With technological advancements and ongoing industrialization, the Global Submerged Arc Wires and Fluxes Market is set to play a crucial role in supporting the development of robust and efficient welding practices.

| Report Metric | Details |

| Report Name | Submerged Arc Wires and Fluxes Market |

| Accounted market size in 2023 | US$ 3436.2 million |

| Forecasted market size in 2030 | US$ 4853.3 million |

| CAGR | 5.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITW Welding Group, Lincoln Electric, Nevatia Steel & Alloys, Oerlikon, Pittarc, ESAB, Gedik Welding, Hobart Brothers, Venus Wire Industries, Vorarc Welding, WB Alloy Welding, Certilas, Bavaria Schweisstechnik, Atlantic China Welding Consumables, Shandong Solid Solder, Shandong Juli Welding, Beijing Jinwei Weld Materials, Baoding Lanyu Welding Material, Hit Welding Industry, Tianjin Golden Bridge Welding Materials Internationl, Tianjin Bridge Welding Materials Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |