What is Global Sheet Cleaner Market?

The global sheet cleaner market is a specialized segment within the broader cleaning industry, focusing on the production and distribution of cleaning solutions specifically designed for sheet materials. These materials can range from metal sheets used in manufacturing to delicate sheets used in the electronics and semiconductor industries. The primary function of sheet cleaners is to remove contaminants such as dust, oil, and other residues that can affect the quality and performance of the sheets. The market encompasses a variety of products, including chemical cleaners, mechanical cleaning devices, and automated cleaning systems. The demand for sheet cleaners is driven by the need for high-quality, contaminant-free sheets in various industries, including electronics, automotive, aerospace, and food processing. As industries continue to advance and require higher standards of cleanliness and precision, the global sheet cleaner market is expected to grow, offering innovative solutions to meet these evolving needs.

Contact, Non-Contact in the Global Sheet Cleaner Market:

In the global sheet cleaner market, there are two primary types of cleaning technologies: contact and non-contact. Contact-based cleaning involves direct physical interaction with the sheet material. This can include methods such as brushing, wiping, or using rollers to remove contaminants. These methods are often effective for removing larger particles and residues but can sometimes risk scratching or damaging delicate surfaces. On the other hand, non-contact cleaning methods do not involve direct physical contact with the sheet material. These methods include techniques such as air blowers, ultrasonic cleaning, and laser cleaning. Air blowers use high-pressure air to blow away dust and particles, making them suitable for delicate surfaces that cannot withstand physical contact. Ultrasonic cleaning uses high-frequency sound waves to create microscopic bubbles in a cleaning solution, which then implode to remove contaminants from the sheet surface. This method is highly effective for cleaning intricate and delicate materials without causing damage. Laser cleaning uses focused laser beams to vaporize contaminants from the sheet surface, offering a precise and non-abrasive cleaning solution. Both contact and non-contact cleaning methods have their advantages and are chosen based on the specific requirements of the sheet material and the industry in which they are used. For instance, in the electronics and semiconductor industries, non-contact methods are often preferred due to the delicate nature of the materials involved. In contrast, the automotive and aerospace industries may use a combination of both methods to ensure thorough cleaning of various sheet materials. The choice between contact and non-contact cleaning methods is influenced by factors such as the type of contaminants, the material of the sheet, and the desired level of cleanliness. As technology continues to advance, the global sheet cleaner market is likely to see further innovations in both contact and non-contact cleaning methods, offering more efficient and effective solutions for a wide range of applications.

Electronics Industry, Semiconductor Industry, Automobile Industry, Food Industry, Aerospace, Others in the Global Sheet Cleaner Market:

The global sheet cleaner market finds extensive usage across various industries, each with its unique requirements and standards for cleanliness. In the electronics industry, sheet cleaners are crucial for maintaining the quality and performance of electronic components. Contaminants on sheet materials can lead to malfunctions or reduced efficiency in electronic devices. Therefore, high-precision cleaning methods, often non-contact, are employed to ensure that the sheets are free from any particles or residues. In the semiconductor industry, the need for ultra-clean environments is even more critical. Semiconductor manufacturing involves intricate processes where even the smallest contaminant can cause defects in the final product. Sheet cleaners in this industry often use advanced non-contact methods such as ultrasonic or laser cleaning to achieve the highest levels of cleanliness. The automobile industry also relies heavily on sheet cleaners to ensure the quality and durability of metal sheets used in vehicle manufacturing. Both contact and non-contact cleaning methods are used to remove oil, dust, and other contaminants that can affect the performance and longevity of automotive parts. In the food industry, sheet cleaners play a vital role in maintaining hygiene and safety standards. Sheets used in food processing and packaging must be free from contaminants to prevent foodborne illnesses and ensure product quality. Non-contact cleaning methods are often preferred to avoid any risk of contamination from cleaning agents. The aerospace industry requires sheet cleaners to maintain the integrity and performance of materials used in aircraft manufacturing. Given the high standards for safety and reliability in this industry, both contact and non-contact cleaning methods are employed to ensure that all sheet materials meet stringent quality requirements. Other industries, such as medical device manufacturing and renewable energy, also benefit from the use of sheet cleaners to maintain the quality and performance of their products. Overall, the global sheet cleaner market provides essential solutions that help various industries meet their specific cleanliness standards, ensuring the quality and reliability of their products.

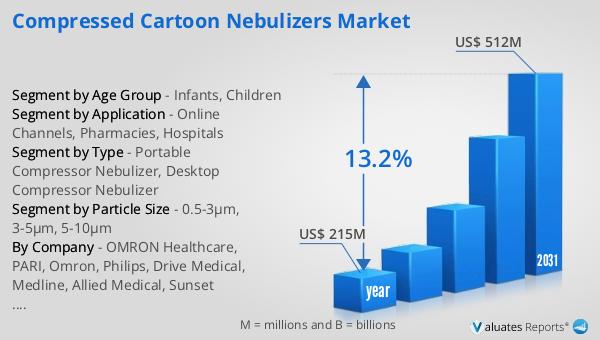

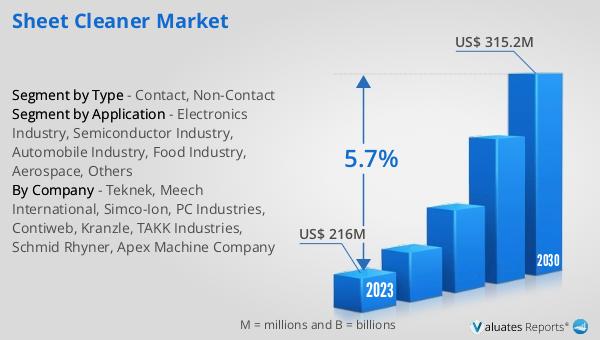

Global Sheet Cleaner Market Outlook:

The global sheet cleaner market was valued at $216 million in 2023 and is projected to grow to $315.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.7% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality, contaminant-free sheet materials across various industries. As industries such as electronics, semiconductors, automotive, food processing, and aerospace continue to advance, the need for effective and efficient cleaning solutions becomes more critical. The market's expansion is also fueled by technological advancements in both contact and non-contact cleaning methods, offering more precise and reliable cleaning solutions. Companies in the sheet cleaner market are continually innovating to meet the evolving needs of their customers, developing new products and technologies that enhance cleaning efficiency and effectiveness. The growing awareness of the importance of cleanliness and quality in manufacturing processes further supports the market's growth. As a result, the global sheet cleaner market is poised for significant growth, providing essential solutions that help various industries maintain high standards of cleanliness and quality.

| Report Metric | Details |

| Report Name | Sheet Cleaner Market |

| Accounted market size in 2023 | US$ 216 million |

| Forecasted market size in 2030 | US$ 315.2 million |

| CAGR | 5.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teknek, Meech International, Simco-Ion, PC Industries, Contiweb, Kranzle, TAKK Industries, Schmid Rhyner, Apex Machine Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |