What is Global Servo Follow-Up Control System Market?

The Global Servo Follow-Up Control System Market is a specialized segment within the broader automation and control systems industry. Servo follow-up control systems are designed to provide precise control over the position, velocity, and acceleration of mechanical components. These systems are integral in applications requiring high accuracy and repeatability, such as robotics, CNC machinery, and various automated manufacturing processes. The market for these systems is driven by the increasing demand for automation across different industries, including automotive, aerospace, and electronics. Technological advancements in servo motors, controllers, and feedback devices have significantly enhanced the performance and reliability of these systems, making them more attractive to end-users. Additionally, the growing trend towards Industry 4.0 and smart manufacturing is further propelling the adoption of servo follow-up control systems. As industries strive for higher efficiency and productivity, the need for advanced control systems that can deliver precise and reliable performance is becoming more critical. This market is characterized by a high level of competition, with numerous players offering a wide range of products and solutions to meet the diverse needs of various industries.

Rotating System, Linear System in the Global Servo Follow-Up Control System Market:

Rotating systems and linear systems are two primary types of servo follow-up control systems used in various applications. Rotating systems are designed to control the rotational movement of mechanical components. These systems are commonly used in applications such as robotic arms, CNC machines, and automated assembly lines. The key components of a rotating system include a servo motor, a controller, and a feedback device such as an encoder or resolver. The servo motor provides the necessary torque to drive the mechanical component, while the controller processes the feedback signals to ensure precise control of the position, velocity, and acceleration. Linear systems, on the other hand, are designed to control the linear movement of mechanical components. These systems are widely used in applications such as linear actuators, conveyor belts, and precision positioning systems. Similar to rotating systems, linear systems also consist of a servo motor, a controller, and a feedback device. However, the servo motor in a linear system is typically coupled with a linear actuator or a ball screw to convert the rotational motion into linear motion. Both rotating and linear systems offer high levels of accuracy and repeatability, making them ideal for applications that require precise control over mechanical movements. The choice between a rotating system and a linear system depends on the specific requirements of the application, such as the type of movement, the load to be controlled, and the desired level of precision. In some cases, a combination of both systems may be used to achieve the desired performance. For example, a robotic arm may use a rotating system for the joints and a linear system for the end effector. The integration of advanced technologies such as artificial intelligence and machine learning is further enhancing the capabilities of these systems, enabling them to perform more complex tasks with higher levels of accuracy and efficiency. As industries continue to adopt automation and smart manufacturing practices, the demand for both rotating and linear servo follow-up control systems is expected to grow.

Industrial, Medical Equipment, Aviation, Others in the Global Servo Follow-Up Control System Market:

The usage of Global Servo Follow-Up Control System Market spans across various sectors, including industrial, medical equipment, aviation, and others. In the industrial sector, these systems are extensively used in manufacturing processes to ensure precise control over machinery and equipment. For instance, in automotive manufacturing, servo follow-up control systems are used in robotic arms for welding, painting, and assembly operations. These systems help in achieving high levels of accuracy and repeatability, which are crucial for maintaining product quality and consistency. In the medical equipment sector, servo follow-up control systems are used in devices such as surgical robots, MRI machines, and patient positioning systems. These systems provide the necessary precision and control required for delicate medical procedures, ensuring patient safety and improving the overall efficiency of medical treatments. In the aviation sector, servo follow-up control systems are used in various applications, including flight simulators, aircraft control surfaces, and unmanned aerial vehicles (UAVs). These systems help in achieving precise control over the movement of aircraft components, enhancing flight safety and performance. Additionally, servo follow-up control systems are also used in other sectors such as renewable energy, where they are employed in wind turbines and solar tracking systems to optimize energy generation. The versatility and high performance of these systems make them suitable for a wide range of applications, driving their adoption across different industries. As technology continues to advance, the capabilities of servo follow-up control systems are expected to improve, further expanding their usage in various sectors.

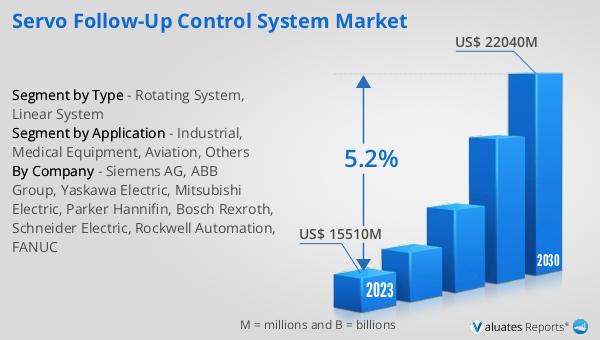

Global Servo Follow-Up Control System Market Outlook:

The global Servo Follow-Up Control System market was valued at US$ 15,510 million in 2023 and is anticipated to reach US$ 22,040 million by 2030, witnessing a CAGR of 5.2% during the forecast period 2024-2030. This growth can be attributed to the increasing demand for automation and precision control in various industries. The market is characterized by a high level of competition, with numerous players offering a wide range of products and solutions to meet the diverse needs of different industries. Technological advancements in servo motors, controllers, and feedback devices have significantly enhanced the performance and reliability of these systems, making them more attractive to end-users. Additionally, the growing trend towards Industry 4.0 and smart manufacturing is further propelling the adoption of servo follow-up control systems. As industries strive for higher efficiency and productivity, the need for advanced control systems that can deliver precise and reliable performance is becoming more critical. The market is also witnessing increased investments in research and development activities to develop innovative solutions that can cater to the evolving needs of various industries. Overall, the global Servo Follow-Up Control System market is poised for significant growth in the coming years, driven by the increasing demand for automation and precision control across different sectors.

| Report Metric | Details |

| Report Name | Servo Follow-Up Control System Market |

| Accounted market size in 2023 | US$ 15510 million |

| Forecasted market size in 2030 | US$ 22040 million |

| CAGR | 5.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Siemens AG, ABB Group, Yaskawa Electric, Mitsubishi Electric, Parker Hannifin, Bosch Rexroth, Schneider Electric, Rockwell Automation, FANUC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |