What is Global Self Piercing Riveting Machine Market?

The Global Self Piercing Riveting Machine Market is a specialized segment within the broader manufacturing equipment industry. These machines are designed to join two or more layers of material, typically metals, without the need for pre-drilled holes. This process involves driving a rivet through the materials, which then flares out to create a strong, durable joint. The market for these machines is driven by their efficiency, reliability, and the high-quality joints they produce. They are widely used in industries where traditional welding or bolting methods are either impractical or less effective. The demand for self-piercing riveting machines is growing due to their application in various sectors such as automotive, aerospace, electronics, and furniture manufacturing. These machines offer a cost-effective and environmentally friendly alternative to traditional fastening methods, making them increasingly popular in modern manufacturing processes.

Servo Cylinder Type Self-piercing Riveting Machine, Ordinary Pressure Cylinder Type Self-piercing Riveting Machine in the Global Self Piercing Riveting Machine Market:

Servo Cylinder Type Self-piercing Riveting Machines and Ordinary Pressure Cylinder Type Self-piercing Riveting Machines are two primary categories within the Global Self Piercing Riveting Machine Market. Servo Cylinder Type machines are known for their precision and control. They use a servo motor to drive the riveting process, allowing for precise control over the force and speed of the rivet insertion. This makes them ideal for applications where high precision is required, such as in the aerospace and electronics industries. These machines can be programmed to handle different materials and thicknesses, making them versatile and adaptable to various manufacturing needs. On the other hand, Ordinary Pressure Cylinder Type machines rely on hydraulic or pneumatic pressure to drive the rivet. While they may not offer the same level of precision as servo-driven machines, they are robust and capable of handling heavy-duty applications. These machines are often used in the automotive and furniture manufacturing industries, where the primary requirement is strength and durability rather than precision. Both types of machines have their unique advantages and are chosen based on the specific needs of the application. The choice between a Servo Cylinder Type and an Ordinary Pressure Cylinder Type machine often comes down to the specific requirements of the manufacturing process, including the materials being joined, the required strength of the joint, and the level of precision needed.

Automotive Industry, Aerospace Industry, Electronics and Electrical Equipment, Furniture Manufacturing in the Global Self Piercing Riveting Machine Market:

The usage of Global Self Piercing Riveting Machines spans several key industries, each benefiting from the unique advantages these machines offer. In the automotive industry, these machines are used extensively for joining body panels, frames, and other structural components. The ability to create strong, durable joints without the need for pre-drilled holes makes them ideal for automotive manufacturing, where speed and efficiency are critical. In the aerospace industry, the precision and reliability of self-piercing riveting machines are highly valued. These machines are used to join various components of aircraft, ensuring that the joints are strong enough to withstand the stresses of flight. The electronics and electrical equipment industry also benefits from the use of these machines. They are used to assemble various components, including circuit boards and enclosures, where precision and reliability are crucial. Finally, in furniture manufacturing, self-piercing riveting machines are used to join metal frames and other components, providing strong and durable joints that can withstand the rigors of everyday use. The versatility and efficiency of these machines make them an invaluable tool in modern manufacturing, helping to improve product quality and reduce production times across various industries.

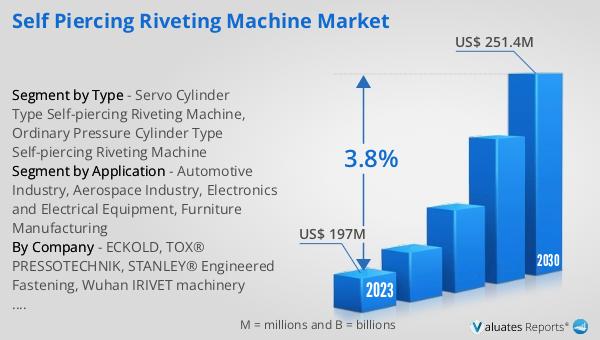

Global Self Piercing Riveting Machine Market Outlook:

The global Self Piercing Riveting Machine market was valued at US$ 197 million in 2023 and is anticipated to reach US$ 251.4 million by 2030, witnessing a CAGR of 3.8% during the forecast period 2024-2030. This market growth is driven by the increasing demand for efficient and reliable joining methods in various industries. The automotive industry, in particular, is a significant driver of this market, as manufacturers seek to improve the efficiency and quality of their production processes. The aerospace industry also contributes to the market growth, with the need for precise and durable joints in aircraft manufacturing. Additionally, the electronics and electrical equipment industry, as well as the furniture manufacturing industry, are adopting self-piercing riveting machines to enhance their production capabilities. The versatility and efficiency of these machines make them an attractive option for manufacturers looking to improve their production processes and product quality. As a result, the global Self Piercing Riveting Machine market is expected to continue its growth trajectory, driven by the increasing adoption of these machines across various industries.

| Report Metric | Details |

| Report Name | Self Piercing Riveting Machine Market |

| Accounted market size in 2023 | US$ 197 million |

| Forecasted market size in 2030 | US$ 251.4 million |

| CAGR | 3.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ECKOLD, TOX® PRESSOTECHNIK, STANLEY® Engineered Fastening, Wuhan IRIVET machinery Co.,Ltd, Insertion Machinery, Omnino Pty Ltd, Fukui Byora Co., Ltd., Heron, Rivetmach Machinery Industries Co., Ltd., Suzhou Swansea Electronic&mechanical Co.,ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |