What is Global Rubber Metal Spring Market?

The Global Rubber Metal Spring Market is a specialized sector within the broader industrial and automotive markets. Rubber metal springs are essential components used in various applications to absorb shocks, reduce vibrations, and provide stability. These springs are made by combining rubber and metal, leveraging the elasticity of rubber and the strength of metal to create a durable and flexible product. They are widely used in automotive, railway, and industrial machinery due to their ability to withstand harsh conditions and provide long-lasting performance. The market for these products is driven by the increasing demand for advanced suspension systems in vehicles, the need for vibration control in industrial machinery, and the growing focus on enhancing passenger comfort in public transportation systems. The global market is characterized by a mix of established players and new entrants, all striving to innovate and improve the performance and durability of rubber metal springs. The market is also influenced by regulatory standards and environmental considerations, pushing manufacturers to develop more sustainable and efficient products. Overall, the Global Rubber Metal Spring Market is poised for steady growth, driven by technological advancements and the increasing need for high-performance components in various industries.

Compression-Mounted, Shear-Mounted in the Global Rubber Metal Spring Market:

Compression-mounted and shear-mounted rubber metal springs are two primary types used in the Global Rubber Metal Spring Market, each serving distinct purposes based on their design and application. Compression-mounted rubber metal springs are designed to absorb and dissipate energy through compression. When a load is applied, the rubber component compresses, and the metal component provides structural support, ensuring that the spring can handle significant forces without deforming. These springs are commonly used in applications where vertical loads are predominant, such as in automotive suspension systems, industrial machinery, and heavy equipment. They are valued for their ability to provide a smooth ride, reduce noise, and enhance the durability of the equipment they are used in. On the other hand, shear-mounted rubber metal springs are designed to absorb energy through shear forces. In these springs, the rubber component is bonded to metal plates, and when a load is applied, the rubber deforms in a shear manner. This design is particularly effective in applications where lateral or horizontal forces are more significant. Shear-mounted springs are often used in railway systems, bridges, and buildings to absorb vibrations and movements caused by dynamic loads, such as trains passing or seismic activities. They help in maintaining structural integrity and ensuring the safety and comfort of passengers. Both types of springs are crucial in their respective applications, providing the necessary balance of flexibility and strength to handle various loads and conditions. The choice between compression-mounted and shear-mounted springs depends on the specific requirements of the application, including the type of load, the direction of forces, and the desired performance characteristics. Manufacturers in the Global Rubber Metal Spring Market continuously innovate to improve the materials and designs of these springs, aiming to enhance their performance, durability, and sustainability. This ongoing innovation is driven by the increasing demand for high-performance components in various industries, including automotive, railway, and construction. As a result, both compression-mounted and shear-mounted rubber metal springs play a vital role in ensuring the efficiency, safety, and reliability of modern machinery and infrastructure.

Electric Locomotives, High-Speed Trains, Metros in the Global Rubber Metal Spring Market:

The usage of rubber metal springs in electric locomotives, high-speed trains, and metros is crucial for ensuring smooth operation, passenger comfort, and safety. In electric locomotives, rubber metal springs are primarily used in the suspension systems to absorb shocks and vibrations caused by the uneven tracks and high speeds. These springs help in maintaining the stability of the locomotive, reducing wear and tear on the components, and enhancing the overall lifespan of the vehicle. The ability of rubber metal springs to provide a smooth ride is particularly important in electric locomotives, where maintaining consistent speed and minimizing disruptions is essential for efficient operation. In high-speed trains, the role of rubber metal springs becomes even more critical due to the higher speeds and greater forces involved. These trains require advanced suspension systems that can handle the increased dynamic loads and provide a comfortable ride for passengers. Rubber metal springs in high-speed trains are designed to absorb both vertical and lateral forces, ensuring that the train remains stable and safe even at high speeds. The use of these springs helps in reducing noise and vibrations, enhancing passenger comfort, and ensuring the structural integrity of the train. In metros, rubber metal springs are used in both the suspension systems and the track infrastructure to absorb vibrations and reduce noise. Metros operate in urban environments where minimizing noise and vibrations is crucial for maintaining a comfortable and safe environment for passengers and nearby residents. Rubber metal springs help in achieving this by absorbing the shocks and vibrations caused by the train's movement, ensuring a smooth and quiet ride. Additionally, these springs are used in the track infrastructure to absorb the dynamic loads and movements caused by the trains, helping in maintaining the stability and longevity of the tracks. Overall, the usage of rubber metal springs in electric locomotives, high-speed trains, and metros is essential for ensuring efficient operation, passenger comfort, and safety. These springs play a vital role in absorbing shocks and vibrations, reducing noise, and maintaining the stability and integrity of the vehicles and infrastructure. The continuous innovation and improvement in the design and materials of rubber metal springs are driven by the increasing demand for high-performance components in the transportation industry. As a result, rubber metal springs are indispensable in modern transportation systems, contributing to the efficiency, safety, and comfort of electric locomotives, high-speed trains, and metros.

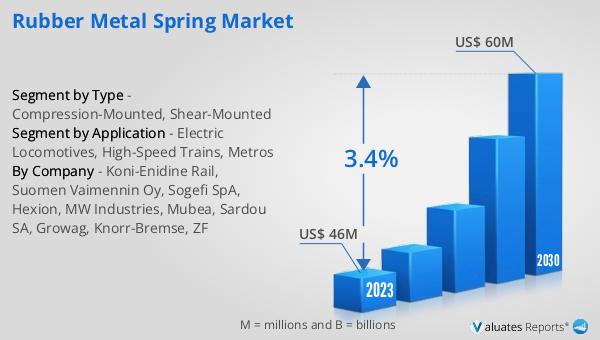

Global Rubber Metal Spring Market Outlook:

The global Rubber Metal Spring market, valued at US$ 46 million in 2023, is projected to grow to US$ 60 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for rubber metal springs across various industries, including automotive, railway, and industrial machinery. The market's expansion is driven by the need for advanced suspension systems, vibration control, and enhanced passenger comfort in public transportation. The steady growth rate underscores the importance of rubber metal springs in modern machinery and infrastructure, highlighting their role in improving performance, durability, and sustainability. As industries continue to evolve and demand more efficient and high-performance components, the Rubber Metal Spring market is expected to witness sustained growth, driven by technological advancements and the ongoing focus on innovation. The market's trajectory reflects the critical role that rubber metal springs play in ensuring the efficiency, safety, and reliability of various applications, making them indispensable in today's industrial and transportation sectors.

| Report Metric | Details |

| Report Name | Rubber Metal Spring Market |

| Accounted market size in 2023 | US$ 46 million |

| Forecasted market size in 2030 | US$ 60 million |

| CAGR | 3.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Koni-Enidine Rail, Suomen Vaimennin Oy, Sogefi SpA, Hexion, MW Industries, Mubea, Sardou SA, Growag, Knorr-Bremse, ZF |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |