What is Global Robotic Soldering Machines Market?

The Global Robotic Soldering Machines Market refers to the worldwide industry focused on the production, distribution, and utilization of robotic machines designed specifically for soldering tasks. Soldering is a process used to join electronic components together by melting a filler metal, known as solder, to create a strong electrical connection. These robotic soldering machines are employed in various industries to enhance precision, efficiency, and consistency in soldering operations. The market encompasses a range of robotic soldering solutions, including desktop and inline machines, each catering to different production needs and scales. With advancements in automation and robotics, these machines have become integral to modern manufacturing processes, particularly in sectors like consumer electronics, automotive electronics, and appliance electronics. The global market for robotic soldering machines is driven by the increasing demand for high-quality electronic products, the need for miniaturization of electronic components, and the growing trend towards automation in manufacturing. As industries continue to seek ways to improve productivity and reduce labor costs, the adoption of robotic soldering machines is expected to rise, making this market a crucial component of the broader electronics manufacturing landscape.

Desktop, Inline in the Global Robotic Soldering Machines Market:

Desktop and inline robotic soldering machines are two primary types of equipment used in the Global Robotic Soldering Machines Market, each serving distinct purposes and applications. Desktop robotic soldering machines are compact, standalone units designed for small to medium-scale production environments. These machines are ideal for tasks that require high precision and flexibility, such as prototyping, small batch production, and specialized soldering jobs. Desktop soldering machines are often used in research and development labs, small electronics manufacturing units, and repair shops. They offer the advantage of being relatively easy to set up and operate, making them suitable for environments where space is limited and production volumes are moderate. On the other hand, inline robotic soldering machines are integrated into larger, automated production lines, catering to high-volume manufacturing needs. These machines are designed to work seamlessly with other automated equipment, such as pick-and-place machines, conveyors, and inspection systems, to create a continuous and efficient production flow. Inline soldering machines are typically used in large-scale electronics manufacturing facilities, where speed, consistency, and throughput are critical. They are capable of handling complex soldering tasks with high precision and can be programmed to perform multiple soldering operations simultaneously. The integration of inline soldering machines into automated production lines helps manufacturers achieve higher productivity, reduce labor costs, and maintain consistent product quality. Both desktop and inline robotic soldering machines play a vital role in the electronics manufacturing industry, addressing different production needs and contributing to the overall efficiency and quality of the manufacturing process. As technology continues to advance, these machines are becoming more sophisticated, with features such as advanced vision systems, real-time monitoring, and machine learning algorithms, further enhancing their capabilities and performance.

Consumer Electronics, Appliances Electronics, Automotive Electronics in the Global Robotic Soldering Machines Market:

The usage of Global Robotic Soldering Machines Market in consumer electronics, appliance electronics, and automotive electronics is extensive and multifaceted. In the consumer electronics sector, robotic soldering machines are employed to assemble a wide range of products, including smartphones, tablets, laptops, and wearable devices. The precision and consistency offered by robotic soldering machines are crucial in ensuring the reliability and performance of these devices, which often contain intricate and densely packed electronic components. The ability to perform high-quality soldering on small and delicate parts helps manufacturers meet the stringent quality standards required in the consumer electronics market. In the appliance electronics sector, robotic soldering machines are used to assemble various household appliances, such as refrigerators, washing machines, microwaves, and air conditioners. These appliances contain numerous electronic components that need to be soldered accurately to ensure proper functionality and durability. Robotic soldering machines help manufacturers achieve consistent soldering quality, reduce production time, and minimize the risk of defects, leading to more reliable and long-lasting appliances. In the automotive electronics sector, robotic soldering machines play a critical role in the production of electronic control units (ECUs), sensors, infotainment systems, and other electronic components used in modern vehicles. The automotive industry demands high levels of precision and reliability, as electronic components are essential for the safety, performance, and comfort of vehicles. Robotic soldering machines help manufacturers meet these demands by providing accurate and consistent soldering, reducing the likelihood of defects and failures. Additionally, the use of robotic soldering machines in automotive electronics production supports the industry's push towards automation and smart manufacturing, enabling manufacturers to increase efficiency and reduce costs. Overall, the application of robotic soldering machines in these three sectors highlights their importance in modern manufacturing, where precision, consistency, and efficiency are paramount.

Global Robotic Soldering Machines Market Outlook:

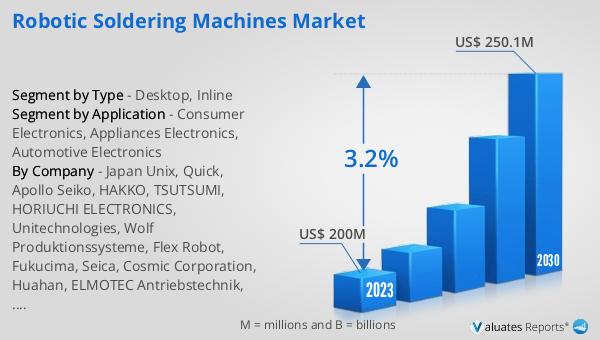

The global Robotic Soldering Machines market was valued at US$ 200 million in 2023 and is anticipated to reach US$ 250.1 million by 2030, witnessing a CAGR of 3.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for automation and precision in soldering processes across various sectors. The projected growth reflects the rising adoption of robotic soldering machines in industries such as consumer electronics, automotive electronics, and appliance electronics, where the need for high-quality and reliable soldering is paramount. The market's expansion is also supported by technological advancements in robotics and automation, which are enhancing the capabilities and efficiency of soldering machines. As manufacturers continue to seek ways to improve productivity, reduce labor costs, and maintain consistent product quality, the demand for robotic soldering machines is expected to grow. This positive market outlook underscores the importance of robotic soldering machines in modern manufacturing and highlights their potential to drive further advancements in the electronics industry.

| Report Metric | Details |

| Report Name | Robotic Soldering Machines Market |

| Accounted market size in 2023 | US$ 200 million |

| Forecasted market size in 2030 | US$ 250.1 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Japan Unix, Quick, Apollo Seiko, HAKKO, TSUTSUMI, HORIUCHI ELECTRONICS, Unitechnologies, Wolf Produktionssysteme, Flex Robot, Fukucima, Seica, Cosmic Corporation, Huahan, ELMOTEC Antriebstechnik, Jeflon, Ruize Technology, Lotuxs |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |