What is Global Pulverized Coal Injection Systems Market?

The Global Pulverized Coal Injection (PCI) Systems Market is a specialized segment within the broader industrial equipment market, focusing on the technology and systems used to inject pulverized coal into blast furnaces. This process is primarily used in the steel manufacturing industry to improve the efficiency and cost-effectiveness of steel production. Pulverized coal injection systems allow for the direct injection of fine coal particles into the blast furnace, which serves as a supplementary fuel to coke. This not only reduces the consumption of expensive coke but also enhances the overall energy efficiency of the furnace. The market for these systems is driven by the growing demand for steel, advancements in injection technology, and the need for cost-effective and environmentally friendly production methods. Key players in this market are continuously innovating to offer more efficient and reliable systems, thereby contributing to the market's growth.

Inward Transfer, Distribution, Metering, Pneumatic Conveying, Other in the Global Pulverized Coal Injection Systems Market:

Inward transfer, distribution, metering, pneumatic conveying, and other processes are integral components of the Global Pulverized Coal Injection Systems Market. Inward transfer refers to the initial stage where raw coal is brought into the system. This involves the transportation of coal from storage facilities to the injection system, ensuring that the coal is available in the required quantities for continuous operation. Distribution is the next critical step, where the pulverized coal is evenly distributed to various parts of the injection system. This ensures that the coal is available at the right place and time, maintaining the efficiency of the injection process. Metering is a crucial aspect that involves measuring the exact amount of coal being injected into the blast furnace. Accurate metering is essential to maintain the desired fuel-to-air ratio, which directly impacts the efficiency and output of the furnace. Pneumatic conveying is the method used to transport the pulverized coal from one part of the system to another using air pressure. This method is preferred due to its efficiency and ability to handle large volumes of coal with minimal spillage and dust generation. Other processes in the PCI systems market include the maintenance and monitoring of the entire system to ensure smooth and uninterrupted operation. This involves regular inspections, troubleshooting, and timely replacement of worn-out components. The integration of advanced technologies such as automation and real-time monitoring systems has further enhanced the efficiency and reliability of PCI systems. These technologies enable operators to monitor the system's performance continuously, detect any anomalies, and take corrective actions promptly. Overall, the inward transfer, distribution, metering, pneumatic conveying, and other processes are critical to the efficient functioning of pulverized coal injection systems, contributing to the overall productivity and cost-effectiveness of steel manufacturing.

Large Steel Mills, Small and Medium-Sized Steel Mills in the Global Pulverized Coal Injection Systems Market:

The usage of Global Pulverized Coal Injection Systems Market varies significantly between large steel mills and small to medium-sized steel mills. Large steel mills, which are often part of multinational corporations, have the financial and technical resources to invest in advanced PCI systems. These mills benefit from economies of scale, allowing them to purchase and maintain high-end equipment that offers superior efficiency and reliability. The use of PCI systems in large steel mills helps in reducing the overall production costs by minimizing the consumption of expensive coke and enhancing the energy efficiency of the blast furnace. Additionally, large steel mills often have stringent environmental regulations to comply with, and PCI systems help in reducing the carbon footprint by optimizing the fuel usage. On the other hand, small and medium-sized steel mills face different challenges. These mills often operate with limited budgets and may not have the same level of access to advanced technology as their larger counterparts. However, the adoption of PCI systems can still offer significant benefits to these mills. By investing in PCI systems, small and medium-sized steel mills can improve their production efficiency and reduce operational costs. The initial investment in PCI systems may be higher, but the long-term savings in fuel costs and improved productivity can offset these expenses. Moreover, the use of PCI systems can help small and medium-sized mills to remain competitive in the market by offering high-quality steel at lower prices. The flexibility and scalability of modern PCI systems make them suitable for mills of all sizes, enabling even smaller operations to benefit from the technology. In summary, while the scale and scope of PCI system usage may differ between large and small to medium-sized steel mills, the underlying benefits of improved efficiency, cost savings, and environmental compliance remain consistent across the board.

Global Pulverized Coal Injection Systems Market Outlook:

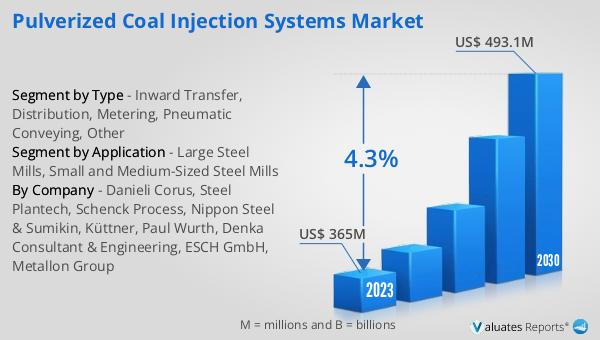

The global Pulverized Coal Injection Systems market was valued at US$ 365 million in 2023 and is anticipated to reach US$ 493.1 million by 2030, witnessing a CAGR of 4.3% during the forecast period 2024-2030. This growth trajectory highlights the increasing demand for PCI systems driven by the need for cost-effective and efficient steel production methods. The market's expansion is also fueled by technological advancements that enhance the performance and reliability of PCI systems. As steel manufacturers continue to seek ways to optimize their production processes and reduce costs, the adoption of PCI systems is expected to rise. The projected growth in the market value underscores the importance of PCI systems in the steel manufacturing industry and their role in driving operational efficiency and sustainability.

| Report Metric | Details |

| Report Name | Pulverized Coal Injection Systems Market |

| Accounted market size in 2023 | US$ 365 million |

| Forecasted market size in 2030 | US$ 493.1 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Danieli Corus, Steel Plantech, Schenck Process, Nippon Steel & Sumikin, Küttner, Paul Wurth, Denka Consultant & Engineering, ESCH GmbH, Metallon Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |