What is Global Pulse Heating Welder Market?

The Global Pulse Heating Welder Market is a specialized segment within the broader welding industry, focusing on the use of pulse heating technology for precision welding applications. Pulse heating welders are designed to deliver controlled, high-frequency pulses of heat to the welding area, ensuring precise and consistent welds. This technology is particularly useful in applications where traditional welding methods may not provide the required level of accuracy or control. The market for pulse heating welders is driven by the increasing demand for high-quality, reliable welding solutions in various industries, including electronics, automotive, aerospace, and medical devices. These welders are known for their ability to produce strong, durable welds with minimal thermal distortion, making them ideal for delicate and intricate welding tasks. As industries continue to advance and require more sophisticated welding techniques, the demand for pulse heating welders is expected to grow, further driving innovation and development in this market.

Gas Metal arc Welding (MIG), Gas Tungsten arc Welding (TIG) in the Global Pulse Heating Welder Market:

Gas Metal Arc Welding (MIG) and Gas Tungsten Arc Welding (TIG) are two prominent welding techniques that are widely used in the Global Pulse Heating Welder Market. MIG welding, also known as Metal Inert Gas welding, involves the use of a continuous wire feed as an electrode and an inert gas to shield the weld from contamination. This method is highly efficient and suitable for welding a variety of metals, including aluminum, stainless steel, and carbon steel. MIG welding is favored for its speed and ease of use, making it a popular choice in industries such as automotive, construction, and manufacturing. On the other hand, TIG welding, or Tungsten Inert Gas welding, uses a non-consumable tungsten electrode to produce the weld. TIG welding is known for its precision and ability to create high-quality welds on thin materials. It is commonly used in applications that require a high degree of accuracy and aesthetic appeal, such as aerospace, art, and sculpture. In the context of the Global Pulse Heating Welder Market, both MIG and TIG welding techniques benefit from the precision and control offered by pulse heating technology. Pulse heating allows for better control of the heat input, reducing the risk of thermal distortion and improving the overall quality of the weld. This is particularly important in industries where the integrity of the weld is critical, such as in the production of medical devices or electronic components. The integration of pulse heating technology with MIG and TIG welding systems enhances their performance, making them more versatile and capable of meeting the stringent requirements of modern manufacturing processes. As a result, the demand for advanced welding solutions that incorporate pulse heating technology is expected to continue to rise, driving further growth and innovation in the Global Pulse Heating Welder Market.

FPC, PCB, LED, Others in the Global Pulse Heating Welder Market:

The usage of Global Pulse Heating Welder Market technology extends to various applications, including Flexible Printed Circuits (FPC), Printed Circuit Boards (PCB), Light Emitting Diodes (LED), and other specialized areas. In the realm of FPC, pulse heating welders are essential for creating reliable and durable connections between flexible circuits and other electronic components. The precision and control offered by pulse heating technology ensure that the delicate materials used in FPCs are not damaged during the welding process, resulting in high-quality, dependable connections. Similarly, in the PCB industry, pulse heating welders are used to attach components to the board with a high degree of accuracy. This is crucial for maintaining the integrity and functionality of the PCB, especially as electronic devices become more compact and complex. The ability to produce consistent, high-quality welds with minimal thermal distortion is a significant advantage in this application. In the LED industry, pulse heating welders play a vital role in the assembly of LED modules and fixtures. The precise control of heat input ensures that the sensitive LED components are not damaged during the welding process, resulting in reliable and long-lasting LED products. Additionally, pulse heating technology is used in other specialized applications, such as the production of medical devices, aerospace components, and automotive parts. In these industries, the ability to produce strong, durable welds with minimal thermal distortion is critical for ensuring the safety and performance of the final product. The versatility and precision of pulse heating welders make them an invaluable tool in these applications, driving their adoption and growth in the Global Pulse Heating Welder Market.

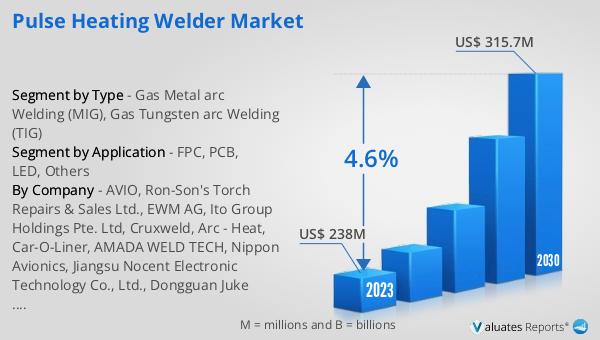

Global Pulse Heating Welder Market Outlook:

The global Pulse Heating Welder market was valued at US$ 238 million in 2023 and is anticipated to reach US$ 315.7 million by 2030, witnessing a CAGR of 4.6% during the forecast period 2024-2030. This growth reflects the increasing demand for advanced welding solutions that offer precision, control, and reliability across various industries. The ability of pulse heating welders to produce high-quality welds with minimal thermal distortion makes them an attractive option for manufacturers looking to improve the quality and performance of their products. As industries continue to evolve and require more sophisticated welding techniques, the demand for pulse heating welders is expected to grow, driving further innovation and development in this market. The projected growth of the Global Pulse Heating Welder Market highlights the importance of this technology in meeting the needs of modern manufacturing processes and ensuring the production of high-quality, reliable products.

| Report Metric | Details |

| Report Name | Pulse Heating Welder Market |

| Accounted market size in 2023 | US$ 238 million |

| Forecasted market size in 2030 | US$ 315.7 million |

| CAGR | 4.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AVIO, Ron-Son's Torch Repairs & Sales Ltd., EWM AG, Ito Group Holdings Pte. Ltd, Cruxweld, Arc - Heat, Car-O-Liner, AMADA WELD TECH, Nippon Avionics, Jiangsu Nocent Electronic Technology Co., Ltd., Dongguan Juke Automation Equipment Co., Ltd., Everprecision Tech Co.,LTD |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |