What is Global Precision Cutting Blades for Encapsulation Market?

The Global Precision Cutting Blades for Encapsulation Market refers to the industry focused on the production and distribution of high-precision cutting blades used in the encapsulation process. Encapsulation is a critical step in the manufacturing of electronic components, where delicate parts are enclosed in protective materials to shield them from environmental factors and mechanical damage. Precision cutting blades are essential in this process as they ensure clean, accurate cuts without damaging the encapsulated components. These blades are used in various applications, including the production of semiconductor devices, microelectromechanical systems (MEMS), and other electronic components. The market for these blades is driven by the increasing demand for miniaturized electronic devices, advancements in manufacturing technologies, and the need for high-quality, reliable components in various industries such as automotive, consumer electronics, and telecommunications.

Metal, Resin in the Global Precision Cutting Blades for Encapsulation Market:

In the Global Precision Cutting Blades for Encapsulation Market, two primary types of blades are commonly used: metal and resin-based blades. Metal blades are typically made from high-speed steel or tungsten carbide, known for their durability, sharpness, and ability to maintain a cutting edge over extended periods. These blades are ideal for cutting through hard materials and are often used in applications requiring high precision and minimal wear. Metal blades are favored in industries where the cutting process involves high temperatures or abrasive materials, as they can withstand such conditions without losing their effectiveness. On the other hand, resin-based blades are made from synthetic materials, often incorporating diamond or other abrasive particles to enhance their cutting capabilities. These blades are designed to provide a smoother cut and are particularly useful in applications where minimizing damage to the encapsulated components is crucial. Resin-based blades are often used in the semiconductor industry, where the delicate nature of the components requires a gentler cutting process. Both metal and resin-based blades play a vital role in the encapsulation process, each offering unique advantages depending on the specific requirements of the application. The choice between metal and resin-based blades depends on factors such as the material being cut, the desired precision, and the operational conditions. As the demand for high-quality electronic components continues to grow, the market for both types of precision cutting blades is expected to expand, driven by advancements in blade technology and the increasing complexity of electronic devices.

Lead Flame Package(eg.QFN), Substate Package (eg.BGA), Others in the Global Precision Cutting Blades for Encapsulation Market:

The usage of Global Precision Cutting Blades for Encapsulation Market spans several critical areas, including Lead Frame Packages (e.g., QFN), Substrate Packages (e.g., BGA), and other specialized applications. In Lead Frame Packages, such as Quad Flat No-lead (QFN) packages, precision cutting blades are essential for trimming and singulating the lead frames. These packages are widely used in various electronic devices due to their compact size and excellent thermal performance. Precision cutting blades ensure that the lead frames are cut accurately, maintaining the integrity of the package and preventing damage to the delicate components inside. In Substrate Packages, such as Ball Grid Array (BGA) packages, precision cutting blades are used to separate the individual packages from the substrate. BGA packages are popular in high-performance applications due to their ability to provide a large number of interconnections in a small footprint. The precision cutting blades used in this process must be capable of making clean, precise cuts to avoid damaging the substrate or the solder balls, which are critical for the package's electrical performance. Other applications of precision cutting blades in the encapsulation market include the production of microelectromechanical systems (MEMS), sensors, and other advanced electronic components. In these applications, the blades must provide a high level of precision to ensure the components' functionality and reliability. The versatility and precision of these blades make them indispensable in the encapsulation process, contributing to the overall quality and performance of the final products.

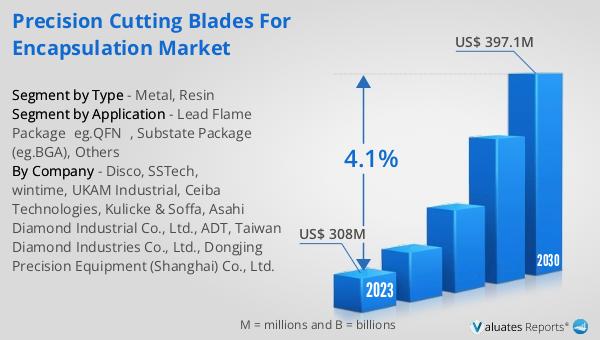

Global Precision Cutting Blades for Encapsulation Market Outlook:

The global Precision Cutting Blades for Encapsulation market was valued at US$ 308 million in 2023 and is anticipated to reach US$ 397.1 million by 2030, witnessing a CAGR of 4.1% during the forecast period 2024-2030. This market growth reflects the increasing demand for high-precision cutting tools in the encapsulation process, driven by the rapid advancements in electronic device manufacturing and the need for miniaturized, high-performance components. The market's expansion is also supported by the continuous development of new materials and technologies that enhance the performance and durability of precision cutting blades. As industries such as automotive, consumer electronics, and telecommunications continue to evolve, the demand for reliable and efficient encapsulation solutions is expected to rise, further propelling the growth of the precision cutting blades market. The projected growth underscores the importance of these blades in ensuring the quality and reliability of electronic components, highlighting their critical role in the manufacturing process.

| Report Metric | Details |

| Report Name | Precision Cutting Blades for Encapsulation Market |

| Accounted market size in 2023 | US$ 308 million |

| Forecasted market size in 2030 | US$ 397.1 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Disco, SSTech, wintime, UKAM Industrial, Ceiba Technologies, Kulicke & Soffa, Asahi Diamond Industrial Co., Ltd., ADT, Taiwan Diamond Industries Co., Ltd., Dongjing Precision Equipment (Shanghai) Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |