What is Global Power Plants Air-Cooled Condenser Market?

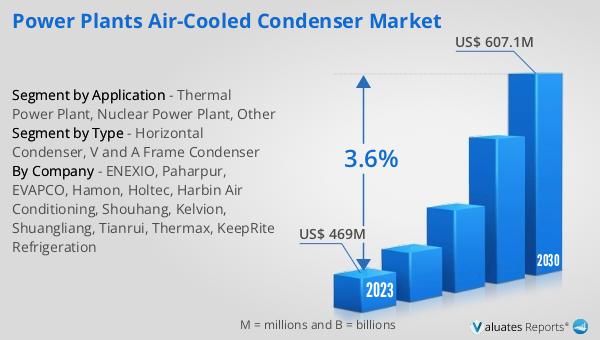

The global Power Plants Air-Cooled Condenser market is a specialized segment within the broader energy and power industry. Air-cooled condensers (ACCs) are critical components used in power plants to condense steam back into water after it has passed through a turbine. Unlike traditional water-cooled systems, ACCs use air to cool and condense the steam, making them particularly useful in areas where water is scarce or expensive. This technology is increasingly being adopted due to its environmental benefits, such as reduced water consumption and lower thermal pollution. The market for these condensers is driven by the growing demand for energy, coupled with stringent environmental regulations that encourage the use of more sustainable cooling methods. In 2023, the global market for Power Plants Air-Cooled Condensers was valued at US$ 469 million and is projected to reach US$ 607.1 million by 2030, growing at a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing recognition of the benefits of air-cooled systems in power generation.

Horizontal Condenser, V and A Frame Condenser in the Global Power Plants Air-Cooled Condenser Market:

Horizontal condensers, V-frame condensers, and A-frame condensers are three primary types of air-cooled condensers used in power plants. Horizontal condensers are designed with a flat, horizontal layout, making them suitable for installations where height restrictions are a concern. These condensers are often used in smaller power plants or in locations where space is limited. They offer the advantage of easy maintenance and lower installation costs. However, their efficiency can be lower compared to other designs due to the limited surface area for heat exchange. V-frame condensers, on the other hand, are designed with a V-shaped configuration, which allows for a larger surface area in a more compact footprint. This design enhances the efficiency of heat exchange and is particularly useful in medium to large power plants. The V-frame design also facilitates better airflow, which can improve the overall performance of the condenser. A-frame condensers are similar to V-frame condensers but are designed with an A-shaped configuration. This design maximizes the surface area for heat exchange and is often used in large power plants where efficiency is a critical factor. A-frame condensers are known for their high performance and reliability, making them a preferred choice for many power plant operators. Each of these condenser types has its own set of advantages and disadvantages, and the choice of which to use often depends on the specific requirements of the power plant, including factors such as space availability, budget, and desired efficiency. The global market for these condensers is growing as power plant operators seek more efficient and environmentally friendly cooling solutions. The increasing demand for energy, coupled with the need to comply with environmental regulations, is driving the adoption of air-cooled condensers in power plants around the world.

Thermal Power Plant, Nuclear Power Plant, Other in the Global Power Plants Air-Cooled Condenser Market:

The usage of air-cooled condensers in thermal power plants is becoming increasingly common due to their environmental and economic benefits. In thermal power plants, steam is generated by burning fossil fuels such as coal, oil, or natural gas. This steam is then used to drive a turbine, which generates electricity. After passing through the turbine, the steam needs to be condensed back into water so it can be reused in the boiler. Traditionally, this condensation process has been done using water-cooled systems, which require large amounts of water and can have significant environmental impacts. Air-cooled condensers offer a more sustainable alternative by using air to cool and condense the steam. This reduces the need for water and minimizes thermal pollution, making them an attractive option for thermal power plants, especially in water-scarce regions. In nuclear power plants, air-cooled condensers are also gaining popularity. Nuclear power plants operate on a similar principle to thermal power plants, using steam to drive a turbine and generate electricity. However, the steam in nuclear power plants is generated by nuclear reactions rather than burning fossil fuels. The use of air-cooled condensers in nuclear power plants offers similar environmental benefits, reducing water consumption and minimizing thermal pollution. Additionally, air-cooled condensers can enhance the safety of nuclear power plants by reducing the risk of water contamination. Other types of power plants, such as renewable energy plants, are also adopting air-cooled condensers. For example, concentrated solar power (CSP) plants use mirrors to focus sunlight onto a receiver, generating steam that drives a turbine. Air-cooled condensers can be used in these plants to condense the steam, offering a sustainable cooling solution that aligns with the environmental goals of renewable energy. Similarly, geothermal power plants, which use heat from the earth to generate steam, can benefit from the use of air-cooled condensers. The adoption of air-cooled condensers in these various types of power plants is driven by the need for more sustainable and efficient cooling solutions. As the global demand for energy continues to grow, the market for air-cooled condensers is expected to expand, offering significant opportunities for innovation and development in this field.

Global Power Plants Air-Cooled Condenser Market Outlook:

The global Power Plants Air-Cooled Condenser market was valued at US$ 469 million in 2023 and is anticipated to reach US$ 607.1 million by 2030, witnessing a CAGR of 3.6% during the forecast period from 2024 to 2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for energy and the need for more sustainable cooling solutions in power plants. The adoption of air-cooled condensers is being propelled by stringent environmental regulations and the growing recognition of their benefits, such as reduced water consumption and lower thermal pollution. As power plant operators seek to comply with these regulations and improve the efficiency of their operations, the demand for air-cooled condensers is expected to rise. This growth is also supported by advancements in technology, which are enhancing the performance and reliability of air-cooled condensers. The market outlook for air-cooled condensers in power plants is positive, with significant opportunities for innovation and development in the coming years.

| Report Metric | Details |

| Report Name | Power Plants Air-Cooled Condenser Market |

| Accounted market size in 2023 | US$ 469 million |

| Forecasted market size in 2030 | US$ 607.1 million |

| CAGR | 3.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ENEXIO, Paharpur, EVAPCO, Hamon, Holtec, Harbin Air Conditioning, Shouhang, Kelvion, Shuangliang, Tianrui, Thermax, KeepRite Refrigeration |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |