What is Global Multistage Chemical Canned Motor Pump Market?

The Global Multistage Chemical Canned Motor Pump Market is a specialized segment within the broader pump industry. These pumps are designed to handle hazardous and toxic chemicals safely and efficiently. Unlike traditional pumps, canned motor pumps have a hermetically sealed motor, which eliminates the need for mechanical seals and reduces the risk of leaks. This makes them particularly suitable for applications where safety and environmental concerns are paramount. The multistage design allows these pumps to achieve higher pressures, making them ideal for transferring fluids over long distances or through complex piping systems. They are widely used in industries such as chemicals, pharmaceuticals, and petrochemicals, where the safe and efficient handling of aggressive fluids is crucial. The market for these pumps is driven by stringent environmental regulations and the need for reliable and maintenance-free pumping solutions. As industries continue to prioritize safety and efficiency, the demand for multistage chemical canned motor pumps is expected to grow.

High Temperature Type, Common Type in the Global Multistage Chemical Canned Motor Pump Market:

High Temperature Type and Common Type are two primary categories within the Global Multistage Chemical Canned Motor Pump Market. High Temperature Type pumps are specifically designed to handle fluids at elevated temperatures. These pumps are constructed with materials that can withstand high thermal stresses, ensuring reliable operation even under extreme conditions. They are commonly used in industries such as petrochemicals and power generation, where processes often involve high-temperature fluids. The ability to handle high temperatures without compromising performance makes these pumps indispensable in such applications. On the other hand, Common Type pumps are designed for general-purpose applications. They are versatile and can handle a wide range of fluids, making them suitable for various industries, including chemicals, pharmaceuticals, and water treatment. These pumps are known for their reliability and ease of maintenance, which makes them a popular choice for many industrial applications. Both types of pumps share the core advantages of canned motor pumps, such as leak-free operation and low maintenance requirements. However, their specific design features cater to different operational needs. High Temperature Type pumps often feature advanced cooling systems and specialized materials to manage the thermal load, while Common Type pumps focus on versatility and ease of use. The choice between these two types depends largely on the specific requirements of the application, such as the nature of the fluid being pumped and the operating conditions. As industries continue to evolve and face new challenges, the demand for both High Temperature Type and Common Type multistage chemical canned motor pumps is expected to remain strong. The ongoing advancements in materials science and pump technology are likely to further enhance the performance and reliability of these pumps, making them even more valuable to industrial operations.

Petroleum Industry, Chemical Industry, Pharmaceutical, New Energy, Pesticides and Fertilizers, Nuclear Power in the Global Multistage Chemical Canned Motor Pump Market:

The Global Multistage Chemical Canned Motor Pump Market finds extensive usage across various industries, including the Petroleum Industry, Chemical Industry, Pharmaceutical, New Energy, Pesticides and Fertilizers, and Nuclear Power. In the Petroleum Industry, these pumps are used to handle crude oil, refined products, and other hydrocarbons. Their leak-free design is crucial for preventing environmental contamination and ensuring the safety of operations. In the Chemical Industry, these pumps are employed to transfer aggressive and corrosive chemicals. Their ability to handle hazardous fluids without leaks makes them ideal for this sector. The Pharmaceutical industry also benefits from these pumps, particularly in the production of drugs and other medical products. The pumps' hermetically sealed design ensures that there is no contamination, which is vital for maintaining the purity of pharmaceutical products. In the New Energy sector, these pumps are used in various applications, including the handling of fluids in renewable energy systems. Their reliability and efficiency make them suitable for these emerging technologies. The Pesticides and Fertilizers industry also relies on these pumps for the safe and efficient transfer of chemicals used in agricultural applications. The leak-free operation of these pumps helps in preventing environmental contamination and ensures the safety of agricultural workers. Lastly, in the Nuclear Power industry, these pumps are used to handle radioactive fluids. Their robust design and leak-free operation are crucial for maintaining the safety and integrity of nuclear power plants. The versatility and reliability of multistage chemical canned motor pumps make them indispensable across these diverse industries. As these industries continue to grow and evolve, the demand for these pumps is expected to increase, driven by the need for safe, efficient, and reliable fluid handling solutions.

Global Multistage Chemical Canned Motor Pump Market Outlook:

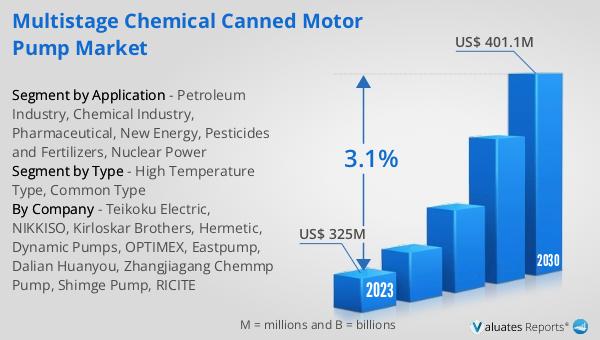

The global Multistage Chemical Canned Motor Pump market was valued at US$ 325 million in 2023 and is anticipated to reach US$ 401.1 million by 2030, witnessing a CAGR of 3.1% during the forecast period 2024-2030. This growth is driven by the increasing demand for safe and efficient fluid handling solutions across various industries. The market's expansion is also supported by stringent environmental regulations that mandate the use of leak-free and maintenance-free pumping systems. As industries continue to prioritize safety and efficiency, the adoption of multistage chemical canned motor pumps is expected to rise. The market's growth trajectory indicates a steady increase in the adoption of these pumps, reflecting their importance in modern industrial operations. The ongoing advancements in pump technology and materials science are likely to further enhance the performance and reliability of these pumps, making them even more valuable to industrial operations. The market outlook suggests a positive trend, with a growing emphasis on safety, efficiency, and environmental sustainability driving the demand for multistage chemical canned motor pumps.

| Report Metric | Details |

| Report Name | Multistage Chemical Canned Motor Pump Market |

| Accounted market size in 2023 | US$ 325 million |

| Forecasted market size in 2030 | US$ 401.1 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teikoku Electric, NIKKISO, Kirloskar Brothers, Hermetic, Dynamic Pumps, OPTIMEX, Eastpump, Dalian Huanyou, Zhangjiagang Chemmp Pump, Shimge Pump, RICITE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |