What is Global Medium Pressure Injection Moulding Ceramic Core Market?

The Global Medium Pressure Injection Moulding Ceramic Core Market is a specialized segment within the broader ceramics industry. This market focuses on the production and application of ceramic cores that are created using medium pressure injection moulding techniques. These ceramic cores are essential components in various high-precision industries due to their ability to withstand extreme temperatures and maintain structural integrity. The process involves injecting ceramic material into a mould under medium pressure, which allows for the creation of complex shapes and fine details that are difficult to achieve with other manufacturing methods. These cores are primarily used in industries such as aerospace, medical, and electronics, where precision and durability are paramount. The market is driven by the increasing demand for high-performance materials that can meet the stringent requirements of these advanced applications. As technology continues to evolve, the need for more sophisticated and reliable ceramic cores is expected to grow, making this market a critical area of focus for manufacturers and researchers alike.

Alumina, Yttria-Stabilized Zirconia (YTZP), Zirconia Toughened Alumina (ZTA), Others in the Global Medium Pressure Injection Moulding Ceramic Core Market:

Alumina, Yttria-Stabilized Zirconia (YTZP), Zirconia Toughened Alumina (ZTA), and other materials play a significant role in the Global Medium Pressure Injection Moulding Ceramic Core Market. Alumina, also known as aluminum oxide, is one of the most widely used ceramic materials due to its excellent thermal and electrical insulation properties, high hardness, and resistance to wear and corrosion. It is commonly used in applications that require high durability and stability under extreme conditions. Yttria-Stabilized Zirconia (YTZP) is another crucial material in this market. It is a type of zirconium oxide that is stabilized with yttrium oxide, which enhances its mechanical properties, making it highly resistant to cracking and thermal shock. YTZP is known for its high strength, toughness, and resistance to wear, making it ideal for applications that demand high performance and reliability. Zirconia Toughened Alumina (ZTA) is a composite material that combines the properties of both alumina and zirconia. This combination results in a material that has improved toughness and strength compared to pure alumina, while still maintaining good thermal and electrical insulation properties. ZTA is often used in applications where a balance of toughness and hardness is required. Other materials used in this market include silicon carbide, silicon nitride, and various other advanced ceramics. These materials are selected based on their specific properties and the requirements of the application. Silicon carbide, for example, is known for its high thermal conductivity and resistance to thermal shock, making it suitable for high-temperature applications. Silicon nitride, on the other hand, is known for its high strength and resistance to wear and corrosion, making it ideal for applications that require high durability and reliability. The choice of material depends on various factors, including the operating environment, mechanical and thermal requirements, and cost considerations. Each material has its unique set of properties that make it suitable for specific applications, and the selection process involves a careful evaluation of these properties to ensure optimal performance. As the demand for high-performance materials continues to grow, the development and use of advanced ceramics in the Global Medium Pressure Injection Moulding Ceramic Core Market are expected to increase, driving innovation and advancements in this field.

Electronic Appliances, Medical Industry, Aerospace, Others in the Global Medium Pressure Injection Moulding Ceramic Core Market:

The Global Medium Pressure Injection Moulding Ceramic Core Market finds extensive usage across various industries, including electronic appliances, the medical industry, aerospace, and others. In the realm of electronic appliances, these ceramic cores are utilized for their excellent thermal and electrical insulation properties. They are integral in the manufacturing of components such as insulators, substrates, and heat sinks, which are essential for the efficient functioning of electronic devices. The ability of these ceramic cores to withstand high temperatures and maintain structural integrity ensures the reliability and longevity of electronic components, making them indispensable in the electronics industry. In the medical industry, medium pressure injection moulding ceramic cores are used in the production of medical devices and equipment that require high precision and biocompatibility. These ceramic cores are employed in the manufacturing of components such as surgical instruments, dental implants, and diagnostic equipment. The biocompatibility, high strength, and resistance to wear and corrosion of these ceramic materials make them ideal for medical applications, where safety and reliability are of utmost importance. The aerospace industry is another significant user of medium pressure injection moulding ceramic cores. In this sector, these ceramic cores are used in the production of components that require high precision, durability, and resistance to extreme temperatures and harsh environments. They are employed in the manufacturing of turbine blades, engine components, and other critical parts that are subjected to high stress and temperature variations. The ability of these ceramic cores to maintain their structural integrity under such conditions ensures the safety and efficiency of aerospace components. Other industries that utilize medium pressure injection moulding ceramic cores include the automotive, defense, and energy sectors. In the automotive industry, these ceramic cores are used in the production of components such as sensors, actuators, and exhaust systems, where high performance and reliability are essential. In the defense sector, they are employed in the manufacturing of components that require high strength and resistance to wear and corrosion, such as armor and weapon systems. In the energy sector, these ceramic cores are used in the production of components for power generation and distribution, where high thermal and electrical insulation properties are required. The versatility and high performance of medium pressure injection moulding ceramic cores make them suitable for a wide range of applications across various industries, driving their demand and growth in the global market.

Global Medium Pressure Injection Moulding Ceramic Core Market Outlook:

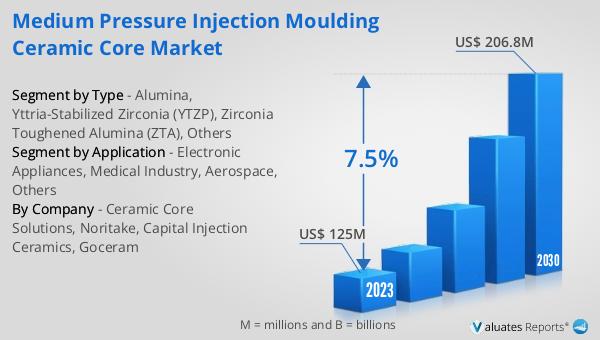

The global Medium Pressure Injection Moulding Ceramic Core market was valued at US$ 125 million in 2023 and is anticipated to reach US$ 206.8 million by 2030, witnessing a CAGR of 7.5% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the medium pressure injection moulding ceramic core market over the next few years. The market's valuation at US$ 125 million in 2023 indicates a strong foundation, and the projected increase to US$ 206.8 million by 2030 underscores the growing demand for these high-performance ceramic cores. The compound annual growth rate (CAGR) of 7.5% during the forecast period reflects the market's robust expansion and the increasing adoption of medium pressure injection moulding ceramic cores across various industries. This growth can be attributed to the rising need for advanced materials that offer superior thermal and electrical insulation properties, high strength, and resistance to wear and corrosion. As industries such as electronics, medical, aerospace, automotive, defense, and energy continue to evolve and demand more sophisticated and reliable components, the medium pressure injection moulding ceramic core market is expected to experience sustained growth. The market outlook emphasizes the importance of innovation and advancements in ceramic materials and manufacturing techniques to meet the stringent requirements of these advanced applications. As a result, manufacturers and researchers are likely to focus on developing new and improved ceramic cores that can deliver enhanced performance and reliability, further driving the market's growth and expansion.

| Report Metric | Details |

| Report Name | Medium Pressure Injection Moulding Ceramic Core Market |

| Accounted market size in 2023 | US$ 125 million |

| Forecasted market size in 2030 | US$ 206.8 million |

| CAGR | 7.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ceramic Core Solutions, Noritake, Capital Injection Ceramics, Goceram |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |