What is Global Liquid Cooling Charging Equipment Market?

The Global Liquid Cooling Charging Equipment Market refers to the industry focused on the development, production, and distribution of advanced cooling systems used in charging equipment for electric vehicles (EVs). These systems are designed to manage the heat generated during the charging process, ensuring that the equipment operates efficiently and safely. Liquid cooling is preferred over air cooling due to its superior thermal management capabilities, which are crucial for maintaining the performance and longevity of high-power charging stations. The market encompasses various types of liquid cooling technologies, including water-cooled and oil-cooled systems, each offering distinct advantages depending on the application. As the demand for electric vehicles continues to rise globally, the need for efficient and reliable charging infrastructure is also increasing, driving the growth of the liquid cooling charging equipment market. This market is characterized by continuous innovation and technological advancements aimed at enhancing the efficiency, safety, and cost-effectiveness of EV charging solutions.

Water Cooled, Oil Cooled in the Global Liquid Cooling Charging Equipment Market:

Water-cooled and oil-cooled systems are two primary types of liquid cooling technologies used in the Global Liquid Cooling Charging Equipment Market. Water-cooled systems utilize water as the primary cooling medium. These systems are highly efficient in transferring heat away from the charging equipment, thanks to water's excellent thermal conductivity. Water-cooled systems are typically used in high-power charging stations where rapid heat dissipation is crucial. They are designed with components such as pumps, heat exchangers, and cooling plates that work together to circulate water and remove heat from the system. One of the main advantages of water-cooled systems is their ability to maintain a consistent temperature, which is essential for the optimal performance of charging equipment. However, these systems require regular maintenance to prevent issues such as corrosion and scaling, which can affect their efficiency and longevity. On the other hand, oil-cooled systems use oil as the cooling medium. Oil has a higher boiling point than water, making it suitable for applications where the charging equipment operates at extremely high temperatures. Oil-cooled systems are often used in environments where water cooling might not be feasible due to the risk of freezing or where electrical insulation is required. These systems are designed with components such as oil pumps, radiators, and cooling fins that facilitate the circulation and cooling of the oil. One of the key benefits of oil-cooled systems is their ability to provide effective cooling without the risk of corrosion, which is a common issue in water-cooled systems. Additionally, oil-cooled systems can operate in a wider range of temperatures, making them versatile for various applications. Both water-cooled and oil-cooled systems have their unique advantages and are chosen based on specific requirements of the charging equipment and the operating environment. Water-cooled systems are preferred for their high efficiency and ability to maintain consistent temperatures, making them ideal for high-power charging stations. However, they require regular maintenance to ensure optimal performance. Oil-cooled systems, while less efficient in terms of thermal conductivity compared to water-cooled systems, offer advantages such as higher operating temperature ranges and resistance to corrosion. These systems are suitable for applications where water cooling is not practical or where additional electrical insulation is needed. The choice between water-cooled and oil-cooled systems ultimately depends on factors such as the power requirements of the charging equipment, the operating environment, and the specific cooling needs of the application. As the Global Liquid Cooling Charging Equipment Market continues to evolve, both water-cooled and oil-cooled systems will play a crucial role in ensuring the efficient and reliable operation of EV charging infrastructure.

Commercial Vehicle, Passenger Vehicle in the Global Liquid Cooling Charging Equipment Market:

The usage of Global Liquid Cooling Charging Equipment Market in commercial vehicles and passenger vehicles is pivotal for the efficient operation of electric vehicle (EV) charging infrastructure. In commercial vehicles, which include buses, trucks, and delivery vans, the demand for high-power charging solutions is significant due to the larger battery capacities and higher energy requirements. Liquid cooling systems, particularly water-cooled systems, are essential in these applications to manage the substantial heat generated during the charging process. These systems ensure that the charging equipment operates within safe temperature limits, preventing overheating and potential damage. The ability to maintain consistent temperatures is crucial for the reliability and longevity of the charging infrastructure, which is often subjected to continuous and high-power usage in commercial settings. Additionally, the efficiency of water-cooled systems helps in reducing the overall charging time, which is a critical factor for commercial vehicles that need to minimize downtime and maximize operational efficiency. In passenger vehicles, the usage of liquid cooling charging equipment is equally important, albeit with different requirements compared to commercial vehicles. Passenger vehicles, which include cars and SUVs, typically have smaller battery capacities and lower energy requirements than commercial vehicles. However, the need for efficient and reliable charging solutions remains paramount. Liquid cooling systems, both water-cooled and oil-cooled, are used to ensure that the charging equipment operates efficiently and safely. Water-cooled systems are often preferred for their superior thermal management capabilities, which help in maintaining the performance and longevity of the charging equipment. These systems are particularly beneficial in high-power charging stations, where rapid heat dissipation is necessary to prevent overheating. On the other hand, oil-cooled systems are used in applications where higher operating temperatures are expected or where additional electrical insulation is required. The versatility of oil-cooled systems makes them suitable for various passenger vehicle charging applications, ensuring that the charging equipment operates reliably under different conditions. The integration of liquid cooling systems in both commercial and passenger vehicle charging infrastructure is driven by the need for efficient thermal management. In commercial vehicles, the focus is on managing the high heat loads generated during rapid and high-power charging sessions. Water-cooled systems are particularly effective in these scenarios, providing the necessary cooling to ensure safe and efficient operation. In passenger vehicles, the emphasis is on maintaining the performance and longevity of the charging equipment, with both water-cooled and oil-cooled systems offering distinct advantages depending on the specific application. The choice of cooling system is influenced by factors such as the power requirements of the charging equipment, the operating environment, and the specific cooling needs of the application. As the demand for electric vehicles continues to grow, the importance of efficient and reliable charging infrastructure cannot be overstated. The Global Liquid Cooling Charging Equipment Market plays a crucial role in meeting this demand, providing the necessary thermal management solutions to ensure the safe and efficient operation of EV charging infrastructure for both commercial and passenger vehicles.

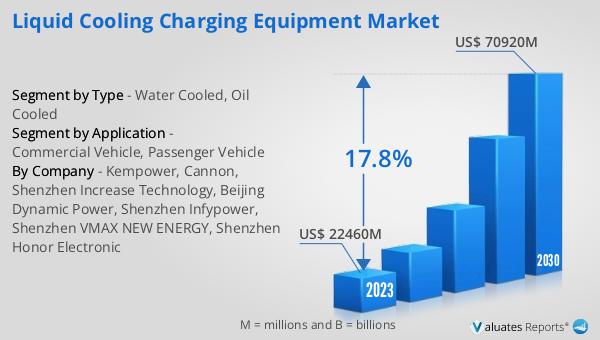

Global Liquid Cooling Charging Equipment Market Outlook:

The global Liquid Cooling Charging Equipment market was valued at US$ 22,460 million in 2023 and is anticipated to reach US$ 70,920 million by 2030, witnessing a CAGR of 17.8% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for efficient and reliable charging solutions for electric vehicles (EVs) across the globe. The market's expansion is driven by the rising adoption of EVs, which necessitates the development of advanced charging infrastructure capable of managing the heat generated during the charging process. Liquid cooling systems, including water-cooled and oil-cooled technologies, are essential in ensuring that the charging equipment operates efficiently and safely. These systems provide superior thermal management, which is crucial for maintaining the performance and longevity of high-power charging stations. As the EV market continues to grow, the need for robust and efficient charging solutions will drive the demand for liquid cooling charging equipment, contributing to the market's substantial growth over the forecast period.

| Report Metric | Details |

| Report Name | Liquid Cooling Charging Equipment Market |

| Accounted market size in 2023 | US$ 22460 million |

| Forecasted market size in 2030 | US$ 70920 million |

| CAGR | 17.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kempower, Cannon, Shenzhen Increase Technology, Beijing Dynamic Power, Shenzhen Infypower, Shenzhen VMAX NEW ENERGY, Shenzhen Honor Electronic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |