What is Global Industrial Inspection Camera Market?

The Global Industrial Inspection Camera Market refers to the industry focused on the production and distribution of cameras designed for industrial inspection purposes. These cameras are used to inspect, monitor, and analyze various industrial processes and components, ensuring quality control and operational efficiency. They are essential tools in industries such as automotive, robotics, semiconductors, photovoltaics, electronics, and food and beverages. These cameras can detect defects, measure dimensions, and provide visual documentation, which helps in maintaining high standards of production and safety. The market for these cameras is growing due to the increasing demand for automation and precision in industrial processes. Technological advancements, such as high-resolution imaging and enhanced connectivity features, are also driving the market forward. The global industrial inspection camera market is characterized by a wide range of products, including single-lens and dual-lens cameras, each offering unique benefits for different applications.

Single Lens, Dual Lens in the Global Industrial Inspection Camera Market:

Single-lens and dual-lens cameras are two primary types of industrial inspection cameras used in various industries. Single-lens cameras are equipped with one lens and are typically used for straightforward inspection tasks. They are known for their simplicity, ease of use, and cost-effectiveness. Single-lens cameras are ideal for applications where a single viewpoint is sufficient to capture the necessary details. They are commonly used in industries such as electronics and food and beverages, where the inspection of small components or products is required. On the other hand, dual-lens cameras are equipped with two lenses, allowing them to capture images from two different perspectives simultaneously. This feature is particularly useful in applications where depth perception and 3D imaging are crucial. Dual-lens cameras are often used in more complex inspection tasks, such as in the automotive and robotics industries, where precise measurements and detailed analysis are required. The dual-lens setup provides a more comprehensive view of the inspected object, enabling better detection of defects and anomalies. Additionally, dual-lens cameras can offer stereoscopic imaging, which enhances the ability to measure dimensions and distances accurately. This makes them suitable for applications in the semiconductor and photovoltaic industries, where precision is paramount. Both single-lens and dual-lens cameras have their unique advantages and are chosen based on the specific requirements of the inspection task. The choice between single-lens and dual-lens cameras depends on factors such as the complexity of the inspection, the need for depth perception, and the level of detail required. As technology continues to advance, both types of cameras are expected to evolve, offering even more sophisticated features and capabilities to meet the growing demands of various industries.

Automotive, Robotics, Semiconductors, Photovoltaics, Electronics, Food and Beverages, Others in the Global Industrial Inspection Camera Market:

The usage of global industrial inspection cameras spans across several key industries, each benefiting from the unique capabilities of these advanced imaging tools. In the automotive industry, inspection cameras are used to examine engine components, body structures, and assembly lines to ensure that all parts meet stringent quality standards. They help in detecting defects, measuring dimensions, and verifying the proper assembly of components, thereby enhancing the overall quality and safety of vehicles. In the robotics industry, inspection cameras are integrated into robotic systems to enable precise navigation, object recognition, and quality control. These cameras provide robots with the ability to see and analyze their environment, making them more efficient and reliable in performing complex tasks. In the semiconductor industry, inspection cameras are used to inspect wafers, chips, and other components for defects and irregularities. High-resolution imaging and advanced analysis capabilities are crucial in this industry to ensure the production of high-quality semiconductor devices. In the photovoltaics industry, inspection cameras are used to examine solar panels and cells for defects, cracks, and other issues that could affect their performance. These cameras help in maintaining the efficiency and reliability of solar energy systems. In the electronics industry, inspection cameras are used to inspect circuit boards, connectors, and other electronic components. They help in identifying defects, ensuring proper assembly, and verifying the functionality of electronic devices. In the food and beverages industry, inspection cameras are used to inspect packaging, labels, and products for quality and safety. They help in detecting contaminants, verifying packaging integrity, and ensuring that products meet regulatory standards. Other industries that benefit from the use of inspection cameras include aerospace, pharmaceuticals, and manufacturing, where these cameras play a crucial role in maintaining quality control and operational efficiency.

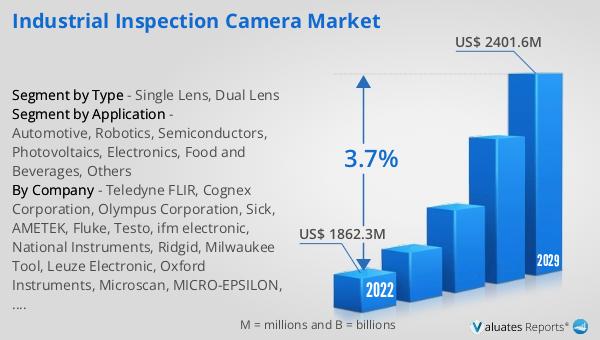

Global Industrial Inspection Camera Market Outlook:

The global industrial inspection camera market was valued at approximately $1,862.3 million in 2023 and is projected to grow to around $2,401.6 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.7% during the forecast period from 2024 to 2030. This steady growth can be attributed to the increasing demand for high-quality inspection tools across various industries. As industries continue to adopt automation and advanced technologies, the need for reliable and efficient inspection cameras is expected to rise. These cameras play a crucial role in ensuring quality control, operational efficiency, and safety in industrial processes. The market's growth is also driven by technological advancements, such as high-resolution imaging, enhanced connectivity features, and the development of more sophisticated single-lens and dual-lens cameras. As a result, the global industrial inspection camera market is poised for significant growth in the coming years, meeting the evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Industrial Inspection Camera Market |

| Accounted market size in 2023 | US$ 1862.3 million |

| Forecasted market size in 2030 | US$ 2401.6 million |

| CAGR | 3.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teledyne FLIR, Cognex Corporation, Olympus Corporation, Sick, AMETEK, Fluke, Testo, ifm electronic, National Instruments, Ridgid, Milwaukee Tool, Leuze Electronic, Oxford Instruments, Microscan, MICRO-EPSILON, Vision Research, Baumer, General Tools & Instruments, Vitronic, Raptor Photonics, Whistler, Teslong, Allied Vision, Imperx, Vividia |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |