What is Global Industrial Accumulation Roller Chains Market?

The Global Industrial Accumulation Roller Chains Market refers to the worldwide industry involved in the production, distribution, and utilization of roller chains specifically designed for accumulation processes in various industrial applications. These roller chains are essential components in conveyor systems, enabling the smooth and efficient movement of goods and materials. They are widely used in sectors such as manufacturing, packaging, food and beverage, and other industries where precise and reliable material handling is crucial. The market encompasses a range of products, including different types of roller chains made from various materials like carbon steel, stainless steel, and plastics. The demand for these roller chains is driven by the need for automation, increased production efficiency, and the growing emphasis on reducing downtime and maintenance costs in industrial operations. As industries continue to evolve and adopt advanced technologies, the Global Industrial Accumulation Roller Chains Market is expected to witness steady growth, driven by the ongoing need for efficient and reliable material handling solutions.

Carbon Steel, Stainless Steel, Plastics in the Global Industrial Accumulation Roller Chains Market:

Carbon steel, stainless steel, and plastics are three primary materials used in the manufacturing of industrial accumulation roller chains, each offering distinct advantages and applications within the Global Industrial Accumulation Roller Chains Market. Carbon steel roller chains are known for their strength and durability, making them suitable for heavy-duty applications where high tensile strength is required. These chains are often used in environments where they are subjected to significant mechanical stress and wear. However, carbon steel chains are prone to corrosion, which can limit their use in certain environments unless they are coated or treated to enhance their resistance to rust and corrosion. Stainless steel roller chains, on the other hand, offer excellent resistance to corrosion and are ideal for applications where hygiene and cleanliness are paramount, such as in the food and beverage industry. Stainless steel chains are also resistant to chemicals and can withstand extreme temperatures, making them suitable for use in harsh environments. Their durability and low maintenance requirements make them a preferred choice in industries where reliability and longevity are critical. Plastics, including engineered plastics and polymer-based materials, are increasingly being used in the production of roller chains due to their lightweight, corrosion resistance, and low noise operation. Plastic roller chains are particularly advantageous in applications where weight reduction is essential, and where the chains are not subjected to heavy loads. They are also suitable for use in environments where metal chains would be prone to corrosion or where noise reduction is a priority. Additionally, plastic chains can be designed to be self-lubricating, reducing the need for regular maintenance and lubrication. Each of these materials brings unique properties to the table, allowing manufacturers to select the most appropriate type of roller chain for their specific application needs. The choice of material depends on various factors, including the operating environment, load requirements, maintenance considerations, and cost constraints. As industries continue to innovate and seek more efficient and reliable material handling solutions, the demand for roller chains made from these diverse materials is expected to grow, driving advancements in material technology and manufacturing processes within the Global Industrial Accumulation Roller Chains Market.

Manufacturing, Packaging, Food & Beverage, Others in the Global Industrial Accumulation Roller Chains Market:

The usage of Global Industrial Accumulation Roller Chains Market spans across various sectors, including manufacturing, packaging, food and beverage, and others, each benefiting from the unique advantages these chains offer. In the manufacturing sector, accumulation roller chains are integral to conveyor systems that facilitate the movement of parts and products along assembly lines. These chains ensure smooth and efficient material handling, reducing downtime and increasing production efficiency. They are used in a wide range of manufacturing processes, from automotive and electronics to textiles and machinery, where precise and reliable movement of components is essential. In the packaging industry, accumulation roller chains play a crucial role in the handling and transportation of packaged goods. They are used in conveyor systems that move products through various stages of packaging, including filling, sealing, labeling, and palletizing. The ability of these chains to accumulate products without causing damage or disruption is particularly valuable in high-speed packaging lines, where maintaining product integrity and minimizing downtime are critical. The food and beverage industry also relies heavily on accumulation roller chains for efficient material handling. These chains are used in conveyor systems that transport raw materials, ingredients, and finished products through various stages of production, processing, and packaging. Stainless steel roller chains are particularly popular in this sector due to their corrosion resistance and ability to maintain hygiene standards. The use of accumulation roller chains in the food and beverage industry helps ensure that products are handled safely and efficiently, reducing the risk of contamination and spoilage. Beyond manufacturing, packaging, and food and beverage, accumulation roller chains find applications in other industries such as pharmaceuticals, logistics, and warehousing. In the pharmaceutical industry, these chains are used in conveyor systems that handle delicate and high-value products, ensuring precise and reliable movement through various stages of production and packaging. In logistics and warehousing, accumulation roller chains facilitate the efficient movement of goods and materials, improving overall operational efficiency and reducing handling times. Overall, the versatility and reliability of accumulation roller chains make them indispensable in a wide range of industrial applications. Their ability to handle diverse materials and products, coupled with their durability and low maintenance requirements, ensures that they continue to be a preferred choice for industries seeking efficient and reliable material handling solutions. As industries continue to evolve and adopt advanced technologies, the usage of accumulation roller chains is expected to expand, driving further growth and innovation within the Global Industrial Accumulation Roller Chains Market.

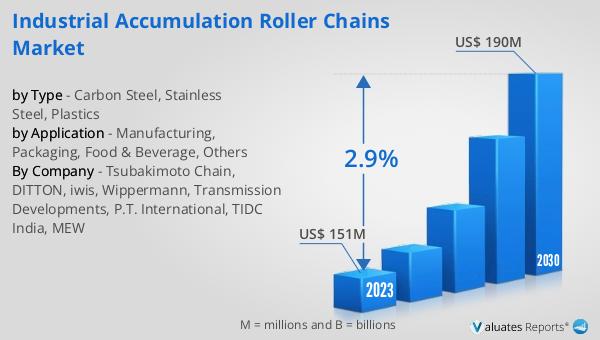

Global Industrial Accumulation Roller Chains Market Outlook:

The global Industrial Accumulation Roller Chains market was valued at US$ 151 million in 2023 and is anticipated to reach US$ 190 million by 2030, witnessing a CAGR of 2.9% during the forecast period 2024-2030. This indicates a steady growth trajectory for the market, driven by the increasing demand for efficient and reliable material handling solutions across various industries. The growth is attributed to the rising adoption of automation and advanced technologies in manufacturing, packaging, food and beverage, and other sectors, which require robust and durable roller chains to ensure smooth and efficient operations. The market's expansion is also supported by the continuous advancements in material technology and manufacturing processes, enabling the production of high-quality roller chains that meet the diverse needs of different industries. As industries continue to prioritize efficiency, reliability, and cost-effectiveness in their operations, the demand for industrial accumulation roller chains is expected to grow, driving further innovation and development within the market.

| Report Metric | Details |

| Report Name | Industrial Accumulation Roller Chains Market |

| Accounted market size in 2023 | US$ 151 million |

| Forecasted market size in 2030 | US$ 190 million |

| CAGR | 2.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tsubakimoto Chain, DITTON, iwis, Wippermann, Transmission Developments, P.T. International, TIDC India, MEW |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |