What is Global Home Appliance PVC Compound Market?

The Global Home Appliance PVC Compound Market refers to the industry focused on the production and distribution of polyvinyl chloride (PVC) compounds specifically designed for use in home appliances. PVC compounds are versatile plastic materials that can be formulated to meet various performance requirements, making them ideal for a wide range of applications in household appliances. These compounds are used in the manufacturing of components such as cables, wires, gaskets, seals, and other parts that require durability, flexibility, and resistance to heat and chemicals. The market encompasses a variety of PVC compounds, including both plasticized and non-plasticized types, each offering distinct properties to cater to specific needs within the home appliance sector. The demand for PVC compounds in this market is driven by the growing consumer electronics industry, advancements in home appliance technology, and the increasing need for energy-efficient and durable materials. As a result, the Global Home Appliance PVC Compound Market plays a crucial role in ensuring the reliability and performance of modern household appliances.

Non-plasticized PVC Compound, Plasticized PVC Compound in the Global Home Appliance PVC Compound Market:

Non-plasticized PVC compounds, also known as rigid PVC, are characterized by their high strength, rigidity, and resistance to impact and abrasion. These properties make them suitable for applications where structural integrity and durability are paramount. In the context of the Global Home Appliance PVC Compound Market, non-plasticized PVC compounds are commonly used in the production of components that require a high degree of mechanical strength and stability. For instance, they are often utilized in the manufacturing of refrigerator liners, washing machine tubs, and air conditioner housings. These applications benefit from the material's ability to withstand physical stress and maintain its shape over time. Additionally, non-plasticized PVC compounds are resistant to chemicals and moisture, making them ideal for use in environments where exposure to water and cleaning agents is common. On the other hand, plasticized PVC compounds, also known as flexible PVC, are formulated with the addition of plasticizers to enhance their flexibility, elasticity, and softness. This makes them suitable for applications that require a high degree of flexibility and ease of installation. In the home appliance sector, plasticized PVC compounds are widely used in the production of cables, wires, gaskets, and seals. For example, the flexible nature of plasticized PVC makes it an excellent choice for electrical wiring and insulation in appliances such as refrigerators, washing machines, and air conditioners. The material's ability to bend and conform to different shapes and spaces ensures reliable electrical connections and reduces the risk of damage during installation and use. Furthermore, plasticized PVC compounds offer excellent resistance to heat and chemicals, which is essential for maintaining the performance and safety of home appliances. The versatility of both non-plasticized and plasticized PVC compounds allows manufacturers to select the most appropriate material for each specific application, ensuring optimal performance and longevity of the final product. As the demand for advanced and energy-efficient home appliances continues to grow, the Global Home Appliance PVC Compound Market is expected to see increased innovation and development in both types of PVC compounds to meet the evolving needs of the industry.

Refrigerator, Washing Machine, Air Conditioner, Television, Other in the Global Home Appliance PVC Compound Market:

The usage of PVC compounds in the Global Home Appliance Market spans across various household appliances, including refrigerators, washing machines, air conditioners, televisions, and other devices. In refrigerators, PVC compounds are used extensively in the production of door gaskets, liners, and insulation materials. The flexibility and durability of plasticized PVC make it ideal for door gaskets, ensuring a tight seal to maintain the internal temperature and improve energy efficiency. Non-plasticized PVC is often used for the inner liners and shelves due to its rigidity and resistance to impact and chemicals. In washing machines, PVC compounds are utilized in the manufacturing of hoses, seals, and electrical insulation. The flexible nature of plasticized PVC makes it suitable for water hoses and seals, providing leak-proof connections and resistance to water pressure. Additionally, the material's electrical insulation properties ensure safe and reliable operation of the washing machine's electrical components. Air conditioners also benefit from the use of PVC compounds, particularly in the production of insulation materials, hoses, and electrical wiring. The heat resistance and flexibility of plasticized PVC make it an excellent choice for insulating the internal components of air conditioners, ensuring efficient cooling and reducing energy consumption. The material's durability and resistance to chemicals also make it suitable for use in hoses and ducts, which are exposed to varying temperatures and environmental conditions. In televisions, PVC compounds are primarily used in the production of electrical cables and connectors. The flexibility and electrical insulation properties of plasticized PVC ensure safe and reliable connections between the various components of the television, reducing the risk of electrical faults and enhancing the overall performance of the device. Other household appliances, such as microwaves, vacuum cleaners, and kitchen appliances, also utilize PVC compounds for various components, including electrical wiring, seals, and gaskets. The versatility and performance characteristics of PVC compounds make them an essential material in the manufacturing of modern home appliances, contributing to their durability, safety, and energy efficiency. As the demand for advanced and reliable household appliances continues to grow, the Global Home Appliance PVC Compound Market is expected to play a crucial role in meeting the industry's needs and driving innovation in material development.

Global Home Appliance PVC Compound Market Outlook:

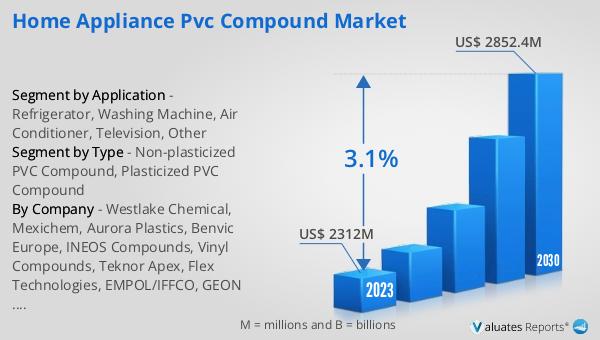

The global Home Appliance PVC Compound market was valued at US$ 2312 million in 2023 and is anticipated to reach US$ 2852.4 million by 2030, witnessing a CAGR of 3.1% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for durable and energy-efficient home appliances. The use of PVC compounds in the manufacturing of household appliances is expected to continue expanding, as manufacturers seek materials that offer a balance of performance, cost-effectiveness, and environmental sustainability. The projected growth in market value reflects the ongoing advancements in PVC compound formulations and their applications in various home appliances. As consumers increasingly prioritize energy efficiency and durability in their purchasing decisions, the demand for high-quality PVC compounds is likely to rise, further propelling the market's growth. The anticipated increase in market value also underscores the importance of innovation and development in the PVC compound industry, as manufacturers strive to meet the evolving needs of the home appliance sector. Overall, the Global Home Appliance PVC Compound Market is poised for significant growth, driven by the continuous advancements in material technology and the rising demand for reliable and efficient household appliances.

| Report Metric | Details |

| Report Name | Home Appliance PVC Compound Market |

| Accounted market size in 2023 | US$ 2312 million |

| Forecasted market size in 2030 | US$ 2852.4 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Westlake Chemical, Mexichem, Aurora Plastics, Benvic Europe, INEOS Compounds, Vinyl Compounds, Teknor Apex, Flex Technologies, EMPOL/IFFCO, GEON Performance Solutions, S&E Specialty Polymers, Sylvin Technologies, Konnark Polymer, Mazda Plastic, Thevinyl, ACTEGA, Avient Corporation, Hanwha, Kingfa, Alphagary, RIKEN, Orinko Advanced Plastics, Guangdong Silver Age Sci & Tech, China General Nuclear Power, MEGA Compound, SHENZHEN HOPEFINDER POLYMER |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |