What is Global High Precision Welding Machine Market?

The Global High Precision Welding Machine Market refers to the worldwide industry focused on the production and distribution of welding machines that offer high precision and accuracy. These machines are essential in various industries where exact welding is crucial, such as automotive, aerospace, electronics, and manufacturing. High precision welding machines are designed to perform intricate welding tasks with minimal errors, ensuring strong and reliable joints. They utilize advanced technologies to control the welding process, including parameters like heat, speed, and pressure, to achieve the desired results. The market for these machines is driven by the increasing demand for high-quality welding in complex applications, advancements in welding technology, and the need for automation in manufacturing processes. As industries continue to evolve and require more precise and efficient welding solutions, the global high precision welding machine market is expected to grow significantly.

Arc Welding Machine, Resistance Welding Machine, Laser Welding Machine, Plasma Arc Welding Machine, Others in the Global High Precision Welding Machine Market:

Arc welding machines are a staple in the Global High Precision Welding Machine Market, known for their versatility and ability to weld a wide range of metals. These machines use an electric arc to melt the base material and filler rod, creating a strong joint. They are widely used in construction, automotive, and shipbuilding industries due to their robustness and adaptability. Resistance welding machines, on the other hand, use the heat generated by electrical resistance to join materials. This method is highly efficient for mass production and is commonly used in the automotive industry for spot welding car bodies. Laser welding machines represent the cutting edge of welding technology, utilizing focused laser beams to achieve extremely precise welds. These machines are ideal for applications requiring high accuracy and minimal thermal distortion, such as in the aerospace and electronics industries. Plasma arc welding machines are similar to arc welding but use a plasma torch to produce a more concentrated and hotter arc. This allows for deeper penetration and faster welding speeds, making them suitable for thick materials and high-strength applications. Other types of high precision welding machines include ultrasonic welding, which uses high-frequency vibrations to create welds, and electron beam welding, which employs a focused beam of electrons to join materials. Each type of welding machine has its unique advantages and is chosen based on the specific requirements of the application, such as material type, thickness, and desired weld quality. The diversity of welding technologies in the Global High Precision Welding Machine Market ensures that there is a suitable solution for virtually any welding challenge.

Car, Aviation, Electronic Manufacturing in the Global High Precision Welding Machine Market:

The usage of high precision welding machines in the automotive industry is crucial for manufacturing components that require exact specifications and high strength. These machines are used to weld car bodies, frames, and other critical parts, ensuring the safety and durability of the vehicles. In the aviation industry, high precision welding machines are indispensable for producing aircraft components that must withstand extreme conditions and stresses. The precision and reliability of these machines ensure that the welded joints meet the stringent standards required for aviation safety. In electronic manufacturing, high precision welding machines are used to assemble delicate and intricate components, such as circuit boards and microchips. The ability to perform precise welds without damaging sensitive electronic parts is essential for maintaining the functionality and performance of electronic devices. The demand for high precision welding machines in these industries is driven by the need for high-quality, reliable, and efficient welding solutions that can meet the specific requirements of each application. As technology continues to advance, the capabilities of high precision welding machines are expected to expand, further enhancing their usage in various industries.

Global High Precision Welding Machine Market Outlook:

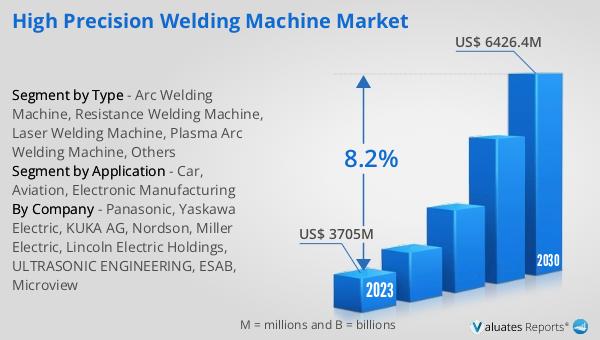

The global High Precision Welding Machine market was valued at US$ 3705 million in 2023 and is anticipated to reach US$ 6426.4 million by 2030, witnessing a CAGR of 8.2% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high precision welding solutions across various industries. The market's expansion is driven by advancements in welding technology, the need for automation in manufacturing processes, and the growing emphasis on producing high-quality and reliable welded joints. As industries such as automotive, aerospace, and electronics continue to evolve and require more precise and efficient welding solutions, the global high precision welding machine market is poised for substantial growth. The market's trajectory indicates a strong future for high precision welding machines, with continuous innovation and development expected to further enhance their capabilities and applications.

| Report Metric | Details |

| Report Name | High Precision Welding Machine Market |

| Accounted market size in 2023 | US$ 3705 million |

| Forecasted market size in 2030 | US$ 6426.4 million |

| CAGR | 8.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Panasonic, Yaskawa Electric, KUKA AG, Nordson, Miller Electric, Lincoln Electric Holdings, ULTRASONIC ENGINEERING, ESAB, Microview |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |