What is Global Fusion Method Laminated Steel Market?

The Global Fusion Method Laminated Steel Market refers to a specialized segment within the steel industry that focuses on producing laminated steel using the fusion method. This method involves bonding multiple layers of steel together to create a composite material that combines the strengths of each layer. The resulting laminated steel is known for its enhanced durability, resistance to corrosion, and improved aesthetic qualities. It is widely used in various industries, including automotive, construction, and packaging, due to its superior performance characteristics. The market for this type of steel is growing as industries seek materials that offer both strength and versatility. The fusion method allows for the production of steel with specific properties tailored to meet the demands of different applications, making it a highly sought-after material in the global market. The increasing demand for high-performance materials in various sectors is driving the growth of the Global Fusion Method Laminated Steel Market.

2-Piece Cans, 3-Piece Cans, Others in the Global Fusion Method Laminated Steel Market:

In the context of the Global Fusion Method Laminated Steel Market, 2-piece cans, 3-piece cans, and other types of containers play a significant role. 2-piece cans are typically made from a single sheet of laminated steel, which is drawn and ironed to form the body and bottom of the can, with a separate lid attached. This type of can is widely used in the beverage industry for packaging soft drinks, beer, and other liquids due to its lightweight and durable nature. The fusion method laminated steel used in these cans provides excellent resistance to corrosion and ensures the contents remain fresh for longer periods. On the other hand, 3-piece cans consist of three separate components: a cylindrical body, a bottom lid, and a top lid. These cans are commonly used for packaging food products, such as canned vegetables, fruits, and soups. The laminated steel used in 3-piece cans offers superior strength and can withstand the high temperatures and pressures involved in the canning process. Additionally, the fusion method ensures a tight seal, preventing any leakage or contamination of the contents. Other types of containers made from fusion method laminated steel include aerosol cans, paint cans, and specialty containers used in the chemical and pharmaceutical industries. These containers benefit from the enhanced properties of laminated steel, such as improved chemical resistance, which is crucial for storing hazardous materials. The versatility of fusion method laminated steel makes it an ideal choice for a wide range of packaging applications, ensuring the safety and integrity of the contents while providing a durable and reliable solution. The growing demand for sustainable and high-performance packaging materials is driving the adoption of fusion method laminated steel in various industries, further boosting the market's growth.

Food & Beverages, Chemical, Consumer Goods, Others in the Global Fusion Method Laminated Steel Market:

The usage of Global Fusion Method Laminated Steel Market in various sectors such as Food & Beverages, Chemical, Consumer Goods, and others is extensive and multifaceted. In the Food & Beverages industry, laminated steel is primarily used for packaging purposes. The fusion method laminated steel provides an excellent barrier against moisture, oxygen, and light, which helps in preserving the freshness and quality of food and beverages for extended periods. This makes it an ideal material for manufacturing cans, containers, and other packaging solutions for products like canned vegetables, fruits, soups, and beverages. The chemical industry also benefits significantly from the use of laminated steel. The enhanced chemical resistance of fusion method laminated steel makes it suitable for storing and transporting hazardous chemicals and substances. Containers made from this material can withstand the corrosive nature of various chemicals, ensuring safe storage and reducing the risk of leaks or spills. In the Consumer Goods sector, laminated steel is used in the production of durable and aesthetically pleasing products. For instance, it is used in the manufacturing of household appliances, electronics, and furniture. The fusion method allows for the creation of steel with specific properties, such as improved strength and resistance to wear and tear, making it an ideal choice for products that require both functionality and visual appeal. Additionally, the laminated steel can be coated with various finishes to enhance its appearance and provide additional protection against environmental factors. Other industries, such as automotive and construction, also utilize fusion method laminated steel for its superior performance characteristics. In the automotive industry, it is used in the production of car bodies, chassis, and other components that require high strength and durability. The construction industry uses laminated steel for structural applications, such as beams, columns, and roofing materials, due to its ability to withstand heavy loads and harsh environmental conditions. The versatility and enhanced properties of fusion method laminated steel make it a valuable material across various sectors, driving its demand and contributing to the growth of the Global Fusion Method Laminated Steel Market.

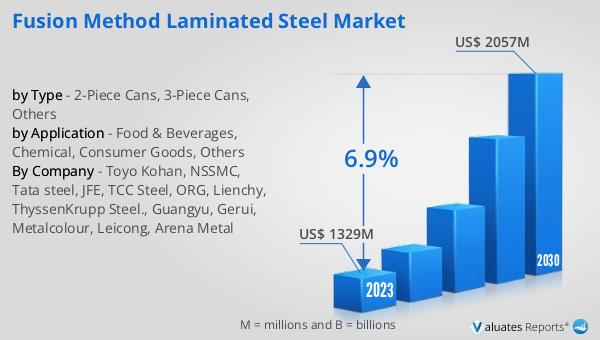

Global Fusion Method Laminated Steel Market Outlook:

The global Fusion Method Laminated Steel market was valued at US$ 1329 million in 2023 and is anticipated to reach US$ 2057 million by 2030, witnessing a CAGR of 6.9% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high-performance materials across various industries. The fusion method laminated steel offers a unique combination of strength, durability, and resistance to corrosion, making it an ideal choice for applications in automotive, construction, packaging, and other sectors. The market's expansion is driven by the need for materials that can meet the stringent requirements of modern industrial applications while providing cost-effective and sustainable solutions. As industries continue to evolve and seek innovative materials to enhance their products and processes, the demand for fusion method laminated steel is expected to rise. The market outlook indicates a positive trend, with substantial growth opportunities in the coming years, driven by advancements in manufacturing technologies and the increasing adoption of laminated steel in various applications. The projected growth of the market underscores the importance of fusion method laminated steel as a critical material in the global industrial landscape.

| Report Metric | Details |

| Report Name | Fusion Method Laminated Steel Market |

| Accounted market size in 2023 | US$ 1329 million |

| Forecasted market size in 2030 | US$ 2057 million |

| CAGR | 6.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toyo Kohan, NSSMC, Tata steel, JFE, TCC Steel, ORG, Lienchy, ThyssenKrupp Steel., Guangyu, Gerui, Metalcolour, Leicong, Arena Metal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |