What is Global Explosion-proof AC Servo Motor Market?

The Global Explosion-proof AC Servo Motor Market refers to the worldwide industry focused on the production and distribution of AC servo motors that are designed to operate safely in hazardous environments where explosive gases, vapors, or dust may be present. These specialized motors are engineered to prevent ignition of the surrounding atmosphere, thereby ensuring safety in industries such as oil and gas, mining, chemical processing, and others where explosive conditions are a risk. The market encompasses a variety of products, including different types of explosion-proof AC servo motors, each tailored to meet specific safety standards and operational requirements. The demand for these motors is driven by stringent safety regulations, the need for reliable and efficient motor performance in hazardous locations, and the growing automation in various industrial sectors. As industries continue to prioritize safety and efficiency, the global explosion-proof AC servo motor market is expected to see significant growth.

Brushless Motors, Brushed Motors in the Global Explosion-proof AC Servo Motor Market:

Brushless motors and brushed motors are two primary types of motors used in the Global Explosion-proof AC Servo Motor Market. Brushless motors, also known as BLDC motors, are designed without brushes, which are components that conduct electrical current between stationary wires and moving parts. This design offers several advantages, including higher efficiency, longer lifespan, and reduced maintenance requirements. Brushless motors are particularly suitable for applications where reliability and performance are critical, such as in hazardous environments where explosion-proof characteristics are essential. These motors are known for their precise control, high torque, and ability to operate at various speeds, making them ideal for use in industries like oil and gas, chemical processing, and mining. On the other hand, brushed motors, which have been in use for a longer time, utilize brushes to conduct electrical current. While they are generally less expensive and simpler in design compared to brushless motors, they come with certain drawbacks. The brushes in these motors wear out over time, leading to higher maintenance needs and shorter operational lifespans. However, brushed motors still find applications in the explosion-proof AC servo motor market due to their cost-effectiveness and simplicity. They are often used in applications where the operational demands are not as stringent, and the cost is a significant consideration. In the context of the explosion-proof AC servo motor market, both brushless and brushed motors are designed to meet stringent safety standards to prevent ignition in hazardous environments. This involves using materials and construction techniques that can withstand explosive conditions and prevent sparks or heat generation that could ignite the surrounding atmosphere. The choice between brushless and brushed motors depends on various factors, including the specific requirements of the application, cost considerations, and the desired balance between performance and maintenance needs. Brushless motors are increasingly preferred in the explosion-proof AC servo motor market due to their superior performance characteristics. They offer better speed control, higher efficiency, and longer operational life, which are critical in industries where downtime can be costly and safety is paramount. The absence of brushes eliminates the risk of sparking, making them inherently safer for use in explosive environments. Additionally, the reduced maintenance requirements of brushless motors translate to lower long-term operational costs, further driving their adoption in the market. Despite the advantages of brushless motors, brushed motors continue to hold a place in the market due to their lower initial cost and simplicity. They are often used in applications where the operational environment is less demanding, and the cost is a significant factor. For instance, in certain industrial applications where the risk of explosion is lower, and the operational demands are not as high, brushed motors can provide a cost-effective solution. In summary, the Global Explosion-proof AC Servo Motor Market includes both brushless and brushed motors, each with its own set of advantages and disadvantages. Brushless motors are favored for their superior performance, efficiency, and safety features, making them ideal for high-demand applications in hazardous environments. Brushed motors, while less advanced, offer a cost-effective solution for less demanding applications. The choice between the two depends on the specific needs of the application, balancing factors such as cost, performance, maintenance, and safety requirements.

Automotive, Electronics, Metal and Machining, Others in the Global Explosion-proof AC Servo Motor Market:

The Global Explosion-proof AC Servo Motor Market finds extensive usage across various industries, including automotive, electronics, metal and machining, and others. In the automotive industry, explosion-proof AC servo motors are crucial for ensuring safety in environments where flammable gases or vapors may be present. These motors are used in various applications, such as in the manufacturing process of vehicles, where precision and reliability are essential. For instance, they are employed in robotic arms for welding, painting, and assembly processes, where the risk of sparks must be minimized to prevent explosions. The high torque and precise control offered by these motors make them ideal for such applications, ensuring both safety and efficiency in the production process. In the electronics industry, explosion-proof AC servo motors are used in the manufacturing of electronic components and devices. The production of electronics often involves the use of volatile chemicals and solvents, creating a potentially explosive environment. Explosion-proof motors ensure that the manufacturing process can be carried out safely, without the risk of igniting these hazardous substances. These motors are used in various stages of production, including assembly lines, testing equipment, and packaging machinery. Their ability to provide precise control and reliable performance is critical in maintaining the quality and safety of electronic products. The metal and machining industry also relies heavily on explosion-proof AC servo motors. In this sector, these motors are used in equipment such as CNC machines, lathes, and milling machines, where the presence of flammable dust or gases can pose a significant risk. The explosion-proof design of these motors ensures that they can operate safely in such environments, preventing any potential ignition sources. The high precision and control offered by AC servo motors are essential for achieving the desired accuracy and quality in metalworking processes. Additionally, the robust construction of these motors allows them to withstand the harsh conditions often encountered in metal and machining applications. Beyond these specific industries, explosion-proof AC servo motors are used in various other sectors where safety is a primary concern. For example, in the oil and gas industry, these motors are used in drilling rigs, pumps, and other equipment that operates in potentially explosive environments. The chemical processing industry also utilizes explosion-proof motors in reactors, mixers, and conveyors to ensure safe operation in the presence of hazardous chemicals. Additionally, these motors are used in the food and beverage industry, where the presence of flammable dust or vapors can create a risk of explosion. The ability of explosion-proof AC servo motors to provide reliable and safe performance in such diverse applications underscores their importance in ensuring safety and efficiency across various industries. In summary, the Global Explosion-proof AC Servo Motor Market plays a vital role in enhancing safety and efficiency across multiple industries. In the automotive sector, these motors are essential for ensuring safe and precise manufacturing processes. In the electronics industry, they enable the safe production of electronic components and devices. The metal and machining industry relies on these motors for achieving high precision and safety in metalworking processes. Additionally, explosion-proof AC servo motors are used in various other sectors, including oil and gas, chemical processing, and food and beverage, where safety is a primary concern. The widespread usage of these motors highlights their critical role in maintaining safety and efficiency in hazardous environments.

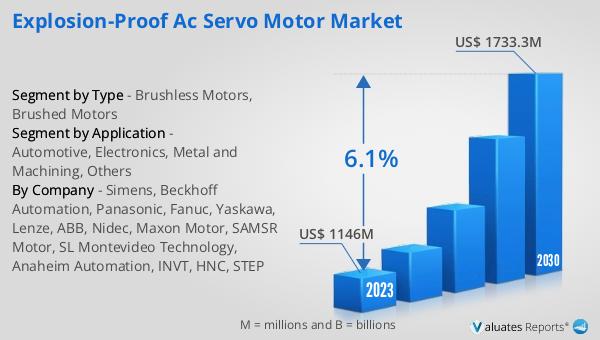

Global Explosion-proof AC Servo Motor Market Outlook:

The global Explosion-proof AC Servo Motor market was valued at US$ 1146 million in 2023 and is projected to reach US$ 1733.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.1% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for safety and efficiency in hazardous environments across various industries. The stringent safety regulations and the need for reliable motor performance in explosive conditions are key factors contributing to the market's expansion. As industries continue to prioritize safety and automation, the adoption of explosion-proof AC servo motors is expected to rise, further propelling market growth.

| Report Metric | Details |

| Report Name | Explosion-proof AC Servo Motor Market |

| Accounted market size in 2023 | US$ 1146 million |

| Forecasted market size in 2030 | US$ 1733.3 million |

| CAGR | 6.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Simens, Beckhoff Automation, Panasonic, Fanuc, Yaskawa, Lenze, ABB, Nidec, Maxon Motor, SAMSR Motor, SL Montevideo Technology, Anaheim Automation, INVT, HNC, STEP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |