What is Global Etching Electronic Special Gas Market?

The Global Etching Electronic Special Gas Market refers to the industry that deals with the production, distribution, and utilization of specialized gases used in the etching processes of electronic components. Etching is a critical step in the manufacturing of various electronic devices, where specific patterns are created on semiconductor materials. These special gases are essential in achieving the precision and efficiency required in modern electronics manufacturing. The market encompasses a wide range of gases, each with unique properties tailored for different etching applications. These gases are used in industries such as integrated circuits, display panels, solar cells, and LEDs. The demand for these gases is driven by the rapid advancements in technology and the increasing need for high-performance electronic devices. As the electronics industry continues to grow, the Global Etching Electronic Special Gas Market is expected to expand, providing essential materials for the production of cutting-edge electronic components.

Fluorine Containing Gas, Chlorine Containing Gas, Oxygen Containing Gas, Others in the Global Etching Electronic Special Gas Market:

Fluorine-containing gases, chlorine-containing gases, oxygen-containing gases, and other specialized gases play a crucial role in the Global Etching Electronic Special Gas Market. Fluorine-containing gases, such as sulfur hexafluoride (SF6) and nitrogen trifluoride (NF3), are widely used due to their high reactivity and ability to create precise etching patterns. These gases are particularly effective in the etching of silicon-based materials, which are commonly used in integrated circuits and display panels. Chlorine-containing gases, including chlorine (Cl2) and hydrogen chloride (HCl), are also essential in the etching process. They are known for their ability to etch a variety of materials, including metals and dielectrics, making them versatile for different applications. Oxygen-containing gases, such as oxygen (O2) and ozone (O3), are used to enhance the etching process by providing additional reactivity and improving the overall efficiency. These gases are often used in combination with other etching gases to achieve the desired results. Other specialized gases, such as argon (Ar) and helium (He), are used as carrier gases or to control the plasma environment during the etching process. Each type of gas has its unique properties and applications, making them indispensable in the production of high-quality electronic components. The careful selection and use of these gases are critical in achieving the precision and performance required in modern electronics manufacturing.

Integrated Circuits, Display Panels, Solar, LED in the Global Etching Electronic Special Gas Market:

The usage of Global Etching Electronic Special Gas Market in various areas such as integrated circuits, display panels, solar cells, and LEDs is extensive and diverse. In the production of integrated circuits, etching gases are used to create intricate patterns on silicon wafers, which form the basis of microchips. These gases enable the precise removal of material, allowing for the creation of complex circuit designs that are essential for the functionality of modern electronic devices. In display panels, etching gases are used to create the fine patterns required for high-resolution screens. The use of these gases ensures that the display panels have the necessary clarity and performance for applications such as smartphones, televisions, and computer monitors. In the solar industry, etching gases are used to create the patterns on solar cells that are necessary for efficient energy conversion. These gases help in the removal of unwanted material, allowing for the creation of high-efficiency solar cells that can capture and convert sunlight into electricity. In the LED industry, etching gases are used to create the patterns on the semiconductor materials that form the basis of LED lights. These gases enable the precise control of the etching process, ensuring that the LEDs have the necessary performance characteristics for applications such as lighting and displays. The use of etching gases in these areas is critical in achieving the precision and performance required for modern electronic devices, making them an essential component of the Global Etching Electronic Special Gas Market.

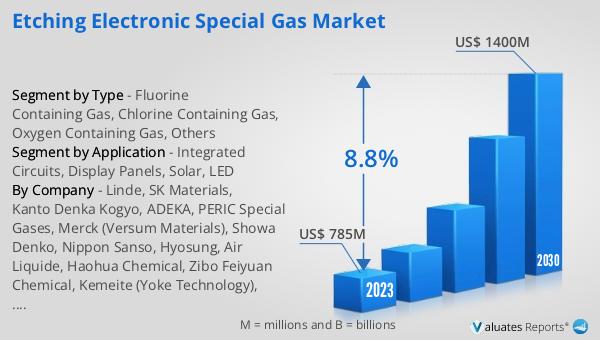

Global Etching Electronic Special Gas Market Outlook:

The global Etching Electronic Special Gas market was valued at US$ 785 million in 2023 and is anticipated to reach US$ 1400 million by 2030, witnessing a CAGR of 8.8% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high-performance electronic devices and the critical role that etching gases play in their production. The market's expansion is driven by advancements in technology and the growing need for precision and efficiency in electronics manufacturing. As the industry continues to evolve, the demand for specialized etching gases is expected to rise, providing essential materials for the production of cutting-edge electronic components. The careful selection and use of these gases are critical in achieving the precision and performance required in modern electronics manufacturing. The market's growth is a testament to the importance of these gases in the production of high-quality electronic devices, and their continued development will be essential in meeting the demands of the rapidly advancing electronics industry.

| Report Metric | Details |

| Report Name | Etching Electronic Special Gas Market |

| Accounted market size in 2023 | US$ 785 million |

| Forecasted market size in 2030 | US$ 1400 million |

| CAGR | 8.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Linde, SK Materials, Kanto Denka Kogyo, ADEKA, PERIC Special Gases, Merck (Versum Materials), Showa Denko, Nippon Sanso, Hyosung, Air Liquide, Haohua Chemical, Zibo Feiyuan Chemical, Kemeite (Yoke Technology), Solvay, Huate Gas, Yongjing Technology, Air Products, Jinhong Gas, Concorde Specialty Gases, Linggas |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |