What is Global Conductive Carbon Coated Copper Foil For Lithium ion Battery Market?

The Global Conductive Carbon Coated Copper Foil for Lithium-ion Battery Market is a specialized segment within the broader battery materials industry. This market focuses on the production and application of copper foil that is coated with a conductive carbon layer, which is essential for enhancing the performance of lithium-ion batteries. These batteries are widely used in various applications, including electric vehicles, consumer electronics, and energy storage systems. The conductive carbon coating on the copper foil improves the electrical conductivity and mechanical strength of the battery, leading to better efficiency and longer lifespan. This market is driven by the increasing demand for high-performance batteries, particularly in the automotive and electronics sectors. The growth of electric vehicles and renewable energy storage solutions has significantly boosted the need for advanced battery materials, making the conductive carbon coated copper foil a critical component in the industry. The market is characterized by continuous innovation and technological advancements aimed at improving the quality and performance of the copper foil to meet the evolving needs of the battery industry.

Ultra-Thin Copper Foil (<12μm), Thin Copper Foil (12-18μm), Common Copper Foil (18-70μm), Thick Copper Foil (>70μm) in the Global Conductive Carbon Coated Copper Foil For Lithium ion Battery Market:

Ultra-Thin Copper Foil (<12μm), Thin Copper Foil (12-18μm), Common Copper Foil (18-70μm), and Thick Copper Foil (>70μm) are different categories of copper foil used in the Global Conductive Carbon Coated Copper Foil for Lithium-ion Battery Market. Each type of copper foil has specific characteristics and applications based on its thickness. Ultra-Thin Copper Foil, with a thickness of less than 12 micrometers, is primarily used in high-performance batteries where space and weight are critical factors. This type of foil offers excellent electrical conductivity and flexibility, making it ideal for compact and lightweight battery designs. Thin Copper Foil, ranging from 12 to 18 micrometers, is commonly used in batteries that require a balance between performance and cost. It provides good electrical conductivity and mechanical strength, making it suitable for a wide range of applications, including consumer electronics and electric vehicles. Common Copper Foil, with a thickness of 18 to 70 micrometers, is the most widely used type in the battery industry. It offers a good balance of performance, cost, and ease of manufacturing, making it suitable for mass production of lithium-ion batteries. This type of foil is used in various applications, including smartphones, laptops, and power tools. Thick Copper Foil, with a thickness of more than 70 micrometers, is used in applications where high current carrying capacity and mechanical strength are required. This type of foil is typically used in large-scale energy storage systems and industrial applications. The choice of copper foil thickness depends on the specific requirements of the battery application, including factors such as energy density, power output, and mechanical durability. The continuous development and optimization of copper foil technology are essential to meet the evolving demands of the lithium-ion battery market. Manufacturers are investing in research and development to improve the quality and performance of copper foil, including advancements in coating techniques and material composition. The goal is to enhance the electrical conductivity, mechanical strength, and overall efficiency of the copper foil to support the growing demand for high-performance batteries. The Global Conductive Carbon Coated Copper Foil for Lithium-ion Battery Market is expected to witness significant growth in the coming years, driven by the increasing adoption of electric vehicles, renewable energy storage solutions, and advanced consumer electronics. The market is characterized by intense competition among key players, with a focus on innovation and technological advancements to gain a competitive edge. The development of new and improved copper foil products is essential to meet the stringent requirements of the battery industry and support the transition to a more sustainable and energy-efficient future.

Automotive, Others in the Global Conductive Carbon Coated Copper Foil For Lithium ion Battery Market:

The usage of Global Conductive Carbon Coated Copper Foil for Lithium-ion Battery Market in the automotive sector is particularly significant. Electric vehicles (EVs) are becoming increasingly popular as a sustainable alternative to traditional internal combustion engine vehicles. The performance and efficiency of EVs largely depend on the quality of their batteries, and conductive carbon coated copper foil plays a crucial role in this regard. The conductive carbon coating enhances the electrical conductivity and mechanical strength of the copper foil, leading to improved battery performance, longer lifespan, and faster charging times. This is essential for EVs, which require high energy density and reliable power output to ensure optimal performance and driving range. The automotive industry is investing heavily in the development of advanced battery technologies, and the demand for high-quality conductive carbon coated copper foil is expected to grow significantly. In addition to electric vehicles, conductive carbon coated copper foil is also used in hybrid vehicles, which combine an internal combustion engine with an electric motor. The batteries in hybrid vehicles require high-performance materials to ensure efficient energy storage and power delivery. The conductive carbon coated copper foil helps to achieve these goals by providing excellent electrical conductivity and mechanical strength. Beyond the automotive sector, conductive carbon coated copper foil is used in various other applications, including consumer electronics, renewable energy storage systems, and industrial applications. In consumer electronics, such as smartphones, laptops, and tablets, the demand for high-performance batteries is driven by the need for longer battery life, faster charging times, and improved overall performance. Conductive carbon coated copper foil helps to meet these requirements by enhancing the electrical conductivity and mechanical strength of the batteries. In renewable energy storage systems, such as solar and wind power, the need for efficient and reliable energy storage solutions is critical. Conductive carbon coated copper foil is used in the batteries of these systems to ensure optimal performance and longevity. The foil's enhanced electrical conductivity and mechanical strength contribute to the overall efficiency and reliability of the energy storage systems, supporting the transition to a more sustainable energy future. In industrial applications, conductive carbon coated copper foil is used in various types of batteries, including those used in power tools, medical devices, and backup power systems. The foil's excellent electrical conductivity and mechanical strength make it suitable for high-performance batteries that require reliable power output and long lifespan. The continuous development and optimization of conductive carbon coated copper foil technology are essential to meet the evolving demands of these diverse applications. Manufacturers are investing in research and development to improve the quality and performance of the foil, including advancements in coating techniques and material composition. The goal is to enhance the electrical conductivity, mechanical strength, and overall efficiency of the foil to support the growing demand for high-performance batteries across various industries. The Global Conductive Carbon Coated Copper Foil for Lithium-ion Battery Market is expected to witness significant growth in the coming years, driven by the increasing adoption of electric vehicles, renewable energy storage solutions, and advanced consumer electronics. The market is characterized by intense competition among key players, with a focus on innovation and technological advancements to gain a competitive edge. The development of new and improved conductive carbon coated copper foil products is essential to meet the stringent requirements of the battery industry and support the transition to a more sustainable and energy-efficient future.

Global Conductive Carbon Coated Copper Foil For Lithium ion Battery Market Outlook:

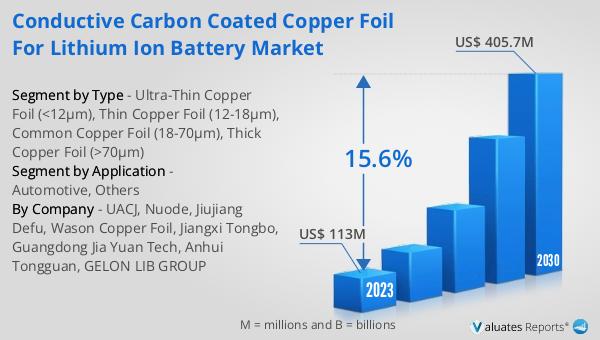

The global market for Conductive Carbon Coated Copper Foil for Lithium-ion Batteries was valued at approximately US$ 113 million in 2023. This market is projected to experience substantial growth, reaching an estimated value of US$ 405.7 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 15.6% during the forecast period from 2024 to 2030. The significant increase in market value underscores the rising demand for high-performance battery materials, driven by the growing adoption of electric vehicles, renewable energy storage solutions, and advanced consumer electronics. The conductive carbon coated copper foil is a critical component in lithium-ion batteries, enhancing their electrical conductivity and mechanical strength, which in turn improves battery performance, lifespan, and efficiency. The market's robust growth is indicative of the ongoing advancements in battery technology and the increasing emphasis on sustainable and energy-efficient solutions across various industries. As the demand for high-quality battery materials continues to rise, the market for conductive carbon coated copper foil is expected to expand, driven by continuous innovation and technological advancements aimed at meeting the evolving needs of the battery industry.

| Report Metric | Details |

| Report Name | Conductive Carbon Coated Copper Foil For Lithium ion Battery Market |

| Accounted market size in 2023 | US$ 113 million |

| Forecasted market size in 2030 | US$ 405.7 million |

| CAGR | 15.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | UACJ, Nuode, Jiujiang Defu, Wason Copper Foil, Jiangxi Tongbo, Guangdong Jia Yuan Tech, Anhui Tongguan, GELON LIB GROUP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |