What is Global CNG Use Stainless Steel Tubing Market?

The global CNG (Compressed Natural Gas) Use Stainless Steel Tubing market is a specialized segment within the broader stainless steel tubing industry. This market focuses on the production and distribution of stainless steel tubes specifically designed for use in CNG applications. These tubes are essential for transporting compressed natural gas safely and efficiently, whether in vehicles, industrial settings, or for residential use. The demand for CNG as an alternative fuel source has been growing due to its environmental benefits and cost-effectiveness compared to traditional fossil fuels. As a result, the need for high-quality, durable stainless steel tubing that can withstand the high pressures and corrosive nature of CNG has also increased. This market includes various types of tubing, such as seamless and welded, each with its own set of advantages and applications. The global CNG Use Stainless Steel Tubing market is characterized by technological advancements, stringent safety standards, and a focus on sustainability, making it a critical component in the transition towards cleaner energy solutions.

Seamless, Welded in the Global CNG Use Stainless Steel Tubing Market:

Seamless and welded stainless steel tubing are two primary types of products in the global CNG Use Stainless Steel Tubing market, each serving distinct purposes and offering unique benefits. Seamless stainless steel tubing is manufactured through a process that involves piercing a solid billet of steel to create a hollow tube, which is then elongated and finished to the desired dimensions. This method results in a tube with no weld seams, providing superior strength and resistance to pressure, making it ideal for high-pressure CNG applications. Seamless tubes are often preferred in critical applications where safety and reliability are paramount, such as in the automotive industry for CNG fuel lines and in industrial settings for high-pressure gas transport. On the other hand, welded stainless steel tubing is produced by rolling a flat strip of steel into a tube shape and then welding the seam. This process is generally more cost-effective and allows for greater flexibility in terms of tube dimensions and wall thickness. Welded tubes are suitable for applications where the pressure requirements are lower, and cost considerations are more critical. They are commonly used in residential and commercial CNG installations, where the operating pressures are not as extreme as in industrial or automotive applications. Both seamless and welded tubes undergo rigorous testing and quality control to ensure they meet the stringent safety and performance standards required for CNG use. The choice between seamless and welded tubing often depends on the specific requirements of the application, including factors such as pressure ratings, cost constraints, and installation conditions. As the global demand for CNG continues to rise, the market for both seamless and welded stainless steel tubing is expected to grow, driven by the need for reliable and efficient gas transport solutions.

Above Ground, Underground in the Global CNG Use Stainless Steel Tubing Market:

The usage of global CNG Use Stainless Steel Tubing can be broadly categorized into above-ground and underground applications, each with its own set of requirements and challenges. Above-ground applications typically involve the installation of stainless steel tubing in environments where the tubes are exposed to the elements and potential physical damage. This includes CNG refueling stations, industrial facilities, and residential areas where CNG is used for heating or cooking. In these settings, the tubing must be highly resistant to corrosion, UV radiation, and mechanical wear and tear. Stainless steel is an ideal material for these applications due to its durability, strength, and resistance to environmental factors. Additionally, above-ground installations often require easy access for maintenance and inspection, making the flexibility and ease of installation of stainless steel tubing a significant advantage. On the other hand, underground applications involve the burial of stainless steel tubing beneath the surface, typically for the transportation of CNG over long distances or for connecting CNG supply lines to end-users. Underground installations pose unique challenges, such as soil corrosion, ground movement, and the need for leak detection systems. Stainless steel tubing used in these applications must be designed to withstand these harsh conditions, with features such as enhanced corrosion resistance and robust jointing systems to prevent leaks. The installation process for underground tubing is also more complex, requiring careful planning and execution to ensure the integrity and safety of the gas transport system. Both above-ground and underground applications benefit from the inherent properties of stainless steel, including its strength, durability, and resistance to corrosion, making it a preferred choice for CNG transport. As the global demand for CNG continues to grow, the need for reliable and efficient stainless steel tubing solutions for both above-ground and underground applications is expected to increase, driving further innovation and development in this market.

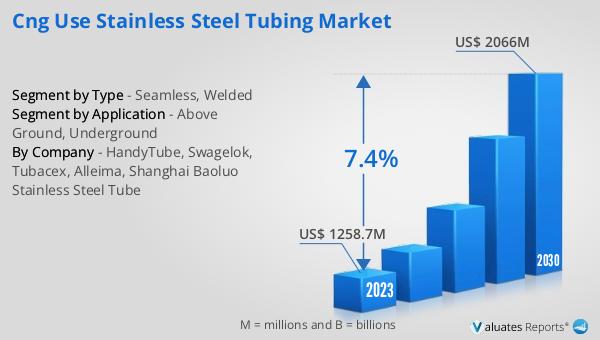

Global CNG Use Stainless Steel Tubing Market Outlook:

The global CNG Use Stainless Steel Tubing market was valued at approximately US$ 1258.7 million in 2023 and is projected to reach around US$ 2066 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.4% during the forecast period from 2024 to 2030. This significant growth is driven by the increasing adoption of CNG as a cleaner and more cost-effective alternative to traditional fossil fuels. The rising environmental concerns and stringent regulations aimed at reducing carbon emissions have further accelerated the shift towards CNG, thereby boosting the demand for high-quality stainless steel tubing designed for CNG applications. The market's expansion is also supported by advancements in stainless steel manufacturing technologies, which have improved the performance and reliability of CNG tubing. Additionally, the growing investments in CNG infrastructure, including refueling stations and distribution networks, are contributing to the market's positive outlook. As more countries and industries embrace CNG as a viable energy source, the demand for durable and efficient stainless steel tubing solutions is expected to continue its upward trajectory, making it a critical component in the global energy landscape.

| Report Metric | Details |

| Report Name | CNG Use Stainless Steel Tubing Market |

| Accounted market size in 2023 | US$ 1258.7 million |

| Forecasted market size in 2030 | US$ 2066 million |

| CAGR | 7.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HandyTube, Swagelok, Tubacex, Alleima, Shanghai Baoluo Stainless Steel Tube |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |