What is Global CNC Foam Cutting Machines Market?

The Global CNC Foam Cutting Machines Market refers to the worldwide industry focused on the production and sale of computer numerical control (CNC) machines specifically designed for cutting foam materials. These machines are used to create precise and intricate shapes from foam, which is a versatile material used in various industries. CNC foam cutting machines utilize advanced software and automated processes to ensure high accuracy and efficiency in cutting operations. The market encompasses a range of machine types, including horizontal and vertical cutters, each suited for different applications and foam types. The demand for these machines is driven by their ability to enhance productivity, reduce material waste, and produce consistent, high-quality cuts. Industries such as packaging, construction, automotive, and aerospace rely on CNC foam cutting machines for their manufacturing processes. The market is characterized by continuous technological advancements, increasing automation, and a growing emphasis on sustainability and energy efficiency. As industries seek to optimize their production processes and meet the demands of modern manufacturing, the Global CNC Foam Cutting Machines Market is expected to experience steady growth.

Horizontal Type, Vertical Type in the Global CNC Foam Cutting Machines Market:

Horizontal and vertical types are two primary categories within the Global CNC Foam Cutting Machines Market, each offering unique advantages and applications. Horizontal CNC foam cutting machines are designed to cut foam blocks horizontally, making them ideal for creating flat, wide shapes and sheets. These machines are commonly used in industries where large foam panels are required, such as in the production of insulation materials, packaging inserts, and architectural elements. Horizontal cutters are known for their ability to handle large volumes of foam efficiently, providing consistent cuts with minimal material waste. They are equipped with advanced software that allows for precise control over cutting parameters, ensuring high accuracy and repeatability. On the other hand, vertical CNC foam cutting machines are designed to cut foam blocks vertically, making them suitable for creating tall, narrow shapes and intricate designs. These machines are often used in industries that require detailed and complex foam components, such as in the production of custom packaging, automotive parts, and aerospace components. Vertical cutters are known for their versatility and ability to handle a wide range of foam densities and types. They are equipped with advanced cutting tools and software that enable intricate and precise cuts, making them ideal for applications that demand high levels of detail and accuracy. Both horizontal and vertical CNC foam cutting machines are equipped with features that enhance their performance and efficiency. These features include automated material handling systems, advanced cutting tools, and user-friendly software interfaces. The machines are designed to minimize material waste and reduce production time, making them cost-effective solutions for foam cutting operations. Additionally, they are built to handle a variety of foam materials, including polyurethane, polystyrene, and polyethylene, ensuring their versatility across different industries. The choice between horizontal and vertical CNC foam cutting machines depends on the specific requirements of the application. For instance, industries that require large, flat foam panels may prefer horizontal cutters, while those that need detailed and intricate foam components may opt for vertical cutters. Both types of machines offer significant advantages in terms of precision, efficiency, and versatility, making them essential tools in modern manufacturing processes. As technology continues to advance, the capabilities of CNC foam cutting machines are expected to improve, further enhancing their performance and expanding their applications. The Global CNC Foam Cutting Machines Market is poised for growth as industries continue to seek innovative solutions for their foam cutting needs.

Architectural, Packaging, Others in the Global CNC Foam Cutting Machines Market:

The usage of Global CNC Foam Cutting Machines Market spans various industries, including architectural, packaging, and others, each benefiting from the precision and efficiency these machines offer. In the architectural sector, CNC foam cutting machines are used to create intricate and detailed architectural elements such as moldings, columns, and decorative panels. These machines allow architects and designers to bring their creative visions to life with high precision and consistency. The ability to cut foam into complex shapes and designs makes CNC foam cutting machines an invaluable tool in the production of custom architectural components. Additionally, the lightweight nature of foam makes it an ideal material for creating large-scale architectural elements that are easy to transport and install. In the packaging industry, CNC foam cutting machines are used to produce custom foam inserts and packaging solutions that provide superior protection for fragile and valuable items. The precision of CNC cutting ensures that each foam insert is tailored to the specific dimensions of the product, offering a snug and secure fit. This level of customization helps prevent damage during transportation and storage, reducing the risk of product returns and enhancing customer satisfaction. CNC foam cutting machines also enable the production of complex packaging designs that can accommodate multiple items within a single package, optimizing space and reducing shipping costs. Beyond architectural and packaging applications, CNC foam cutting machines are used in various other industries, including automotive, aerospace, and entertainment. In the automotive industry, these machines are used to create custom foam components for vehicle interiors, such as seat cushions, armrests, and headrests. The precision of CNC cutting ensures that each component fits perfectly within the vehicle, enhancing comfort and aesthetics. In the aerospace industry, CNC foam cutting machines are used to produce lightweight and durable foam components for aircraft interiors, contributing to weight reduction and fuel efficiency. In the entertainment industry, these machines are used to create props, set pieces, and special effects for movies, theater productions, and theme parks. The versatility of CNC foam cutting machines allows for the creation of a wide range of shapes and designs, making them an essential tool for bringing creative concepts to life. Overall, the usage of CNC foam cutting machines in various industries highlights their importance in modern manufacturing processes. The ability to produce precise, customized, and high-quality foam components makes these machines a valuable asset for businesses seeking to enhance their production capabilities and meet the demands of their customers. As technology continues to advance, the applications of CNC foam cutting machines are expected to expand, further driving their adoption across different industries.

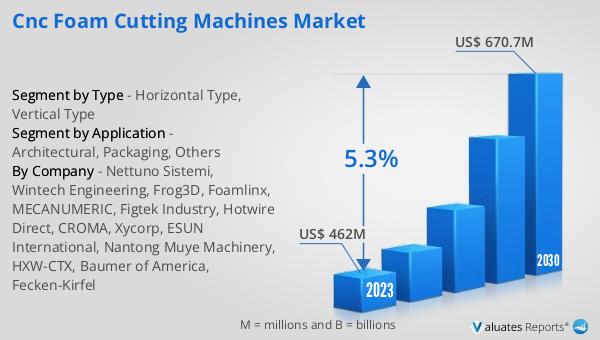

Global CNC Foam Cutting Machines Market Outlook:

The global CNC Foam Cutting Machines market was valued at US$ 462 million in 2023 and is anticipated to reach US$ 670.7 million by 2030, witnessing a CAGR of 5.3% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by increasing demand for precision cutting solutions across various sectors. The market's valuation in 2023 reflects the significant investments and advancements in CNC technology, which have enhanced the efficiency and capabilities of foam cutting machines. As industries continue to seek innovative and cost-effective solutions for their manufacturing processes, the adoption of CNC foam cutting machines is expected to rise. The projected growth to US$ 670.7 million by 2030 underscores the expanding applications of these machines in sectors such as packaging, automotive, aerospace, and construction. The compound annual growth rate (CAGR) of 5.3% highlights the market's potential for sustained development, driven by technological advancements, increasing automation, and a growing emphasis on sustainability. This positive market outlook suggests that the Global CNC Foam Cutting Machines Market will continue to evolve, offering new opportunities for manufacturers and end-users alike.

| Report Metric | Details |

| Report Name | CNC Foam Cutting Machines Market |

| Accounted market size in 2023 | US$ 462 million |

| Forecasted market size in 2030 | US$ 670.7 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nettuno Sistemi, Wintech Engineering, Frog3D, Foamlinx, MECANUMERIC, Figtek Industry, Hotwire Direct, CROMA, Xycorp, ESUN International, Nantong Muye Machinery, HXW-CTX, Baumer of America, Fecken-Kirfel |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |