What is Global CFR Thermoplastic Market?

The Global CFR Thermoplastic Market is a rapidly evolving sector that focuses on the production and application of carbon fiber-reinforced thermoplastics. These materials are known for their exceptional strength-to-weight ratio, making them highly desirable in various industries. CFR thermoplastics combine carbon fibers with thermoplastic resins, resulting in a composite material that is both lightweight and incredibly strong. This unique combination offers significant advantages over traditional materials like metals and non-reinforced plastics, including improved durability, resistance to corrosion, and enhanced performance under stress. The market for CFR thermoplastics is expanding globally, driven by increasing demand in sectors such as aerospace, automotive, and sports equipment. As industries continue to seek materials that offer both high performance and sustainability, the global CFR thermoplastic market is poised for significant growth. The versatility and adaptability of these materials make them suitable for a wide range of applications, further fueling their adoption across various sectors.

Continuous Carbon Fiber, Long Carbon Fiber, Short Carbon Fiber in the Global CFR Thermoplastic Market:

Continuous Carbon Fiber, Long Carbon Fiber, and Short Carbon Fiber are three primary types of carbon fibers used in the Global CFR Thermoplastic Market, each offering distinct properties and applications. Continuous Carbon Fiber is characterized by its long, unbroken strands, which provide superior strength and stiffness. This type of carbon fiber is often used in high-performance applications where maximum strength and minimal weight are crucial, such as in aerospace components and high-end automotive parts. The continuous nature of the fibers allows for the creation of highly durable and resilient materials that can withstand significant stress and strain. Long Carbon Fiber, on the other hand, consists of shorter, but still relatively lengthy strands of carbon fiber. These fibers are typically used in applications that require a balance between strength and flexibility. Long carbon fibers are often found in automotive components, sporting goods, and industrial equipment, where they provide enhanced performance without the need for the extreme strength offered by continuous fibers. Short Carbon Fiber is composed of even shorter strands of carbon fiber, which are often used in applications where ease of processing and cost-effectiveness are more critical than maximum strength. These fibers are commonly used in consumer goods, electronics, and various industrial applications. Despite their shorter length, short carbon fibers still offer significant improvements in strength and durability compared to non-reinforced materials. Each type of carbon fiber brings unique advantages to the table, allowing manufacturers to choose the most appropriate material for their specific needs. The versatility of carbon fibers in the CFR thermoplastic market ensures that there is a suitable option for virtually any application, from high-performance aerospace components to everyday consumer products. As the demand for lightweight, durable, and high-performance materials continues to grow, the use of continuous, long, and short carbon fibers in CFR thermoplastics is expected to expand, driving further innovation and development in this dynamic market.

Aerospace, Automotive, Equipment, Sports Equipment, Others in the Global CFR Thermoplastic Market:

The usage of Global CFR Thermoplastic Market spans across various sectors, including aerospace, automotive, equipment, sports equipment, and others, each benefiting from the unique properties of these advanced materials. In the aerospace industry, CFR thermoplastics are highly valued for their lightweight and high-strength characteristics, which contribute to improved fuel efficiency and performance of aircraft. These materials are used in the manufacturing of various aircraft components, such as fuselage panels, wing structures, and interior parts, where their durability and resistance to extreme conditions are crucial. In the automotive sector, CFR thermoplastics are increasingly being adopted to reduce vehicle weight and enhance fuel efficiency without compromising safety and performance. They are used in the production of structural components, body panels, and interior parts, offering a combination of strength, flexibility, and corrosion resistance that traditional materials cannot match. The equipment industry also benefits from the use of CFR thermoplastics, particularly in the manufacturing of industrial machinery and tools. These materials provide the necessary strength and durability to withstand heavy usage and harsh environments, while their lightweight nature makes handling and installation easier. In the realm of sports equipment, CFR thermoplastics are used to create high-performance gear that is both lightweight and strong. From bicycles and tennis rackets to golf clubs and helmets, these materials enhance the performance and safety of sports equipment, giving athletes a competitive edge. Other sectors, such as consumer electronics and medical devices, also utilize CFR thermoplastics for their superior properties. In consumer electronics, these materials are used to produce lightweight and durable components for smartphones, laptops, and other gadgets. In the medical field, CFR thermoplastics are used in the manufacturing of prosthetics, surgical instruments, and other medical devices, where their biocompatibility and strength are essential. The versatility and adaptability of CFR thermoplastics make them suitable for a wide range of applications, driving their adoption across various industries. As the demand for high-performance, lightweight, and durable materials continues to grow, the usage of CFR thermoplastics in these sectors is expected to expand, further solidifying their position in the global market.

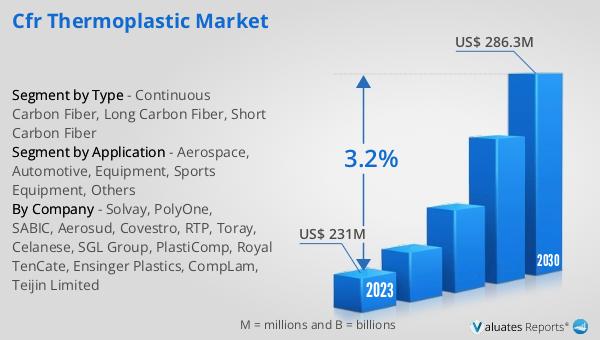

Global CFR Thermoplastic Market Outlook:

The global CFR Thermoplastic market was valued at US$ 231 million in 2023 and is anticipated to reach US$ 286.3 million by 2030, witnessing a CAGR of 3.2% during the forecast period from 2024 to 2030. This market outlook indicates a steady growth trajectory, driven by the increasing demand for lightweight, durable, and high-performance materials across various industries. The aerospace, automotive, and sports equipment sectors, in particular, are expected to be significant contributors to this growth, as they continue to seek advanced materials that offer both performance and sustainability. The projected growth in the CFR thermoplastic market reflects the ongoing advancements in material science and manufacturing technologies, which are enabling the development of more efficient and cost-effective CFR thermoplastic products. As industries continue to prioritize weight reduction, fuel efficiency, and overall performance, the demand for CFR thermoplastics is likely to rise, further driving market expansion. The anticipated growth also underscores the importance of continuous innovation and investment in research and development to meet the evolving needs of various sectors. With a compound annual growth rate of 3.2%, the global CFR thermoplastic market is poised for significant advancements and increased adoption, highlighting its critical role in the future of material science and engineering.

| Report Metric | Details |

| Report Name | CFR Thermoplastic Market |

| Accounted market size in 2023 | US$ 231 million |

| Forecasted market size in 2030 | US$ 286.3 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Solvay, PolyOne, SABIC, Aerosud, Covestro, RTP, Toray, Celanese, SGL Group, PlastiComp, Royal TenCate, Ensinger Plastics, CompLam, Teijin Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |