What is Global Carton Tray Forming Machine Market?

The Global Carton Tray Forming Machine Market refers to the industry that manufactures and sells machines designed to create carton trays. These trays are essential for packaging various products, providing a sturdy and reliable means of transportation and storage. The market encompasses a wide range of machines, from fully automated systems to semi-automatic ones, catering to different production needs and scales. These machines are used across various industries, including food and beverage, electronics, pharmaceuticals, cosmetics, e-commerce, and automotive sectors. The demand for carton tray forming machines is driven by the need for efficient, cost-effective, and sustainable packaging solutions. As businesses continue to seek ways to optimize their packaging processes and reduce waste, the market for these machines is expected to grow. The machines are designed to handle different types of materials, including corrugated cardboard and paperboard, ensuring versatility and adaptability to various packaging requirements.

Full Automatic, Semi Automatic in the Global Carton Tray Forming Machine Market:

Full automatic and semi-automatic carton tray forming machines are two primary categories within the Global Carton Tray Forming Machine Market, each offering distinct advantages and catering to different operational needs. Full automatic machines are designed to perform the entire tray forming process without human intervention, making them ideal for high-volume production environments. These machines are equipped with advanced technology, including programmable logic controllers (PLCs), sensors, and robotic arms, which ensure precision and consistency in tray formation. The automation reduces labor costs and minimizes the risk of human error, leading to higher efficiency and productivity. Full automatic machines are particularly beneficial for large-scale manufacturers who require continuous and rapid production to meet high demand. On the other hand, semi-automatic carton tray forming machines require some level of human involvement, typically in the loading and unloading of materials. These machines are suitable for medium to small-scale operations where flexibility and cost-effectiveness are crucial. Semi-automatic machines offer a balance between automation and manual control, allowing operators to adjust settings and make modifications as needed. This adaptability makes them ideal for businesses that produce a variety of tray sizes and designs. While they may not match the speed and efficiency of full automatic machines, semi-automatic machines provide a more affordable option for companies with lower production volumes or those just starting in the packaging industry. Both types of machines are designed to handle various materials, ensuring that businesses can choose the best option based on their specific needs and budget. The choice between full automatic and semi-automatic machines ultimately depends on factors such as production volume, budget, and the level of customization required. As technology continues to advance, the capabilities of both types of machines are expected to improve, offering even greater efficiency and versatility to meet the evolving demands of the packaging industry.

Food and Beverage, Electronics and Electrical, Pharmaceutical and Medical, Cosmetics and Personal Care, E-commerce and Logistics, Industrial and Automotive in the Global Carton Tray Forming Machine Market:

The usage of Global Carton Tray Forming Machines spans across several key industries, each benefiting from the efficiency and reliability these machines offer. In the food and beverage industry, these machines are essential for packaging products such as fruits, vegetables, baked goods, and beverages. The trays provide a sturdy and hygienic solution for transporting and storing perishable items, ensuring they remain fresh and intact. In the electronics and electrical sector, carton tray forming machines are used to create packaging for delicate components and devices. The trays offer protection against damage during shipping and handling, reducing the risk of costly returns and repairs. The pharmaceutical and medical industry also relies on these machines to package medicines, medical devices, and other healthcare products. The trays ensure that these items are securely contained and protected from contamination, maintaining their efficacy and safety. In the cosmetics and personal care industry, carton tray forming machines are used to package a wide range of products, from skincare and makeup to haircare and fragrances. The trays provide an attractive and functional packaging solution that enhances the presentation and appeal of the products. E-commerce and logistics companies use these machines to create packaging for a variety of goods, ensuring they are securely packed and protected during transit. The trays help to minimize damage and improve customer satisfaction by ensuring that products arrive in perfect condition. In the industrial and automotive sectors, carton tray forming machines are used to package heavy and bulky items, such as machinery parts and automotive components. The trays provide a robust and reliable packaging solution that can withstand the rigors of transportation and storage. Overall, the versatility and efficiency of carton tray forming machines make them an invaluable asset across multiple industries, helping businesses to optimize their packaging processes and improve product protection.

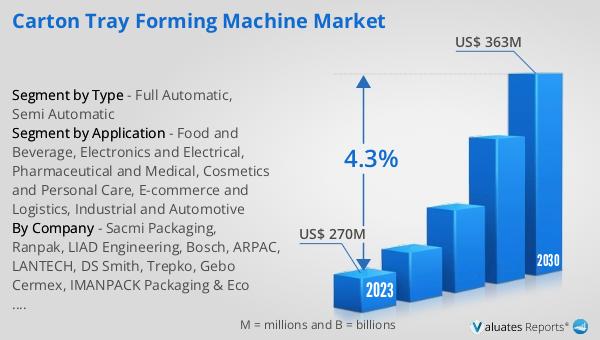

Global Carton Tray Forming Machine Market Outlook:

The global Carton Tray Forming Machine market was valued at US$ 270 million in 2023 and is anticipated to reach US$ 363 million by 2030, witnessing a CAGR of 4.3% during the forecast period 2024-2030. This market outlook highlights the steady growth and increasing demand for carton tray forming machines across various industries. The projected growth indicates a rising need for efficient and reliable packaging solutions that these machines provide. As businesses continue to seek ways to enhance their packaging processes, reduce waste, and improve product protection, the demand for carton tray forming machines is expected to rise. The market's growth is driven by advancements in technology, which have led to the development of more sophisticated and versatile machines. These advancements enable businesses to achieve higher efficiency, precision, and customization in their packaging operations. Additionally, the increasing focus on sustainability and eco-friendly packaging solutions is contributing to the market's expansion. Carton tray forming machines offer a sustainable alternative to traditional packaging methods, as they can handle recyclable materials such as corrugated cardboard and paperboard. This aligns with the growing trend towards environmentally responsible business practices. The market outlook underscores the importance of these machines in meeting the evolving needs of various industries, from food and beverage to electronics, pharmaceuticals, cosmetics, e-commerce, and automotive sectors. As the market continues to grow, businesses are likely to invest in advanced carton tray forming machines to stay competitive and meet the demands of their customers.

| Report Metric | Details |

| Report Name | Carton Tray Forming Machine Market |

| Accounted market size in 2023 | US$ 270 million |

| Forecasted market size in 2030 | US$ 363 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sacmi Packaging, Ranpak, LIAD Engineering, Bosch, ARPAC, LANTECH, DS Smith, Trepko, Gebo Cermex, IMANPACK Packaging & Eco Solutions S.p.a, Ixapack, Carpentier Packaging, DUETTI PACKAGING SRL, Boix Maquinaria S.L, Delta Packaging Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |