What is Global Bridge Anticorrosive Coating Market?

The Global Bridge Anticorrosive Coating Market is a specialized segment within the broader coatings industry, focusing on products designed to protect bridge structures from corrosion. Corrosion is a natural process that deteriorates metal and concrete, leading to structural weaknesses and potential failures. Anticorrosive coatings are essential for extending the lifespan of bridges, ensuring safety, and reducing maintenance costs. These coatings are applied to various parts of a bridge, including the deck, beams, and supports, to create a barrier against environmental factors such as moisture, salt, and pollutants. The market for these coatings is driven by the need for infrastructure maintenance and the construction of new bridges worldwide. With increasing urbanization and the expansion of transportation networks, the demand for durable and long-lasting bridge coatings is on the rise. The market encompasses a variety of coating types, each with specific properties and applications, tailored to meet the diverse needs of different bridge structures and environmental conditions.

Epoxy Coating, Polyurethane Coating, Others in the Global Bridge Anticorrosive Coating Market:

Epoxy coatings are a significant component of the Global Bridge Anticorrosive Coating Market, known for their excellent adhesion, chemical resistance, and durability. These coatings are typically used as primers or topcoats, providing a robust protective layer that can withstand harsh environmental conditions. Epoxy coatings are particularly effective in protecting steel structures from rust and corrosion, making them ideal for use on bridges exposed to marine environments or industrial pollutants. The application process involves mixing two components – a resin and a hardener – which chemically react to form a hard, durable coating. This type of coating is favored for its long-lasting protection and ability to adhere to various substrates, including metal and concrete. Polyurethane coatings, on the other hand, offer superior flexibility and UV resistance, making them suitable for bridge surfaces exposed to sunlight and temperature fluctuations. These coatings are often used as topcoats over epoxy primers, providing an additional layer of protection and enhancing the aesthetic appearance of the bridge. Polyurethane coatings are known for their ability to maintain gloss and color over time, which is crucial for the visual appeal and safety of bridges. Other types of anticorrosive coatings in the market include zinc-rich coatings, which provide sacrificial protection to steel surfaces, and acrylic coatings, known for their quick-drying properties and ease of application. Zinc-rich coatings contain a high percentage of zinc dust, which corrodes preferentially, protecting the underlying steel. This type of coating is often used in conjunction with epoxy and polyurethane systems to provide a comprehensive protective solution. Acrylic coatings, while not as durable as epoxy or polyurethane, offer advantages in terms of application speed and environmental friendliness, as they typically contain fewer volatile organic compounds (VOCs). The choice of coating depends on various factors, including the specific requirements of the bridge, environmental conditions, and maintenance schedules. Each type of coating has its strengths and limitations, and often, a combination of different coatings is used to achieve optimal protection. The Global Bridge Anticorrosive Coating Market continues to evolve, with ongoing research and development aimed at improving the performance and sustainability of these coatings. Innovations in coating technology, such as the development of nanocoatings and environmentally friendly formulations, are expected to drive future growth in this market.

Arch Bridge, Beam Bridge, Cantilever Bridge, Suspension Bridge, Others in the Global Bridge Anticorrosive Coating Market:

The usage of Global Bridge Anticorrosive Coating Market products varies significantly across different types of bridges, each with unique structural and environmental challenges. Arch bridges, known for their curved design and ability to span large distances, require coatings that can protect both the arch and the supporting structures from corrosion. The curved surfaces of arch bridges can create challenges for coating application, necessitating specialized techniques and equipment. Beam bridges, which consist of horizontal beams supported by piers, are among the simplest and most common bridge types. These bridges often require coatings that can protect the beams and piers from moisture and salt, especially in regions with harsh winters or coastal environments. Cantilever bridges, which extend horizontally into space and are supported at only one end, present unique challenges for anticorrosive coatings. The cantilever design creates areas of high stress and potential corrosion, requiring coatings that can provide robust protection and withstand mechanical stresses. Suspension bridges, characterized by their long spans and use of cables to support the bridge deck, require coatings that can protect both the cables and the deck from corrosion. The cables, often made of steel, are particularly susceptible to corrosion and require specialized coatings that can penetrate and protect the individual wires. Other types of bridges, such as truss bridges and cable-stayed bridges, also have specific coating requirements based on their design and environmental exposure. Truss bridges, with their interconnected triangular units, require coatings that can protect the numerous joints and connections from corrosion. Cable-stayed bridges, which use cables directly connected to the bridge towers to support the deck, require coatings that can protect both the cables and the towers from environmental factors. In all these cases, the choice of anticorrosive coating is critical to ensuring the longevity and safety of the bridge. The coatings must be able to withstand the specific environmental conditions, such as humidity, temperature fluctuations, and exposure to salt and pollutants. Regular maintenance and inspection are also essential to ensure that the coatings remain effective and to address any areas of damage or wear. The Global Bridge Anticorrosive Coating Market plays a vital role in providing the products and technologies needed to protect these critical infrastructure assets.

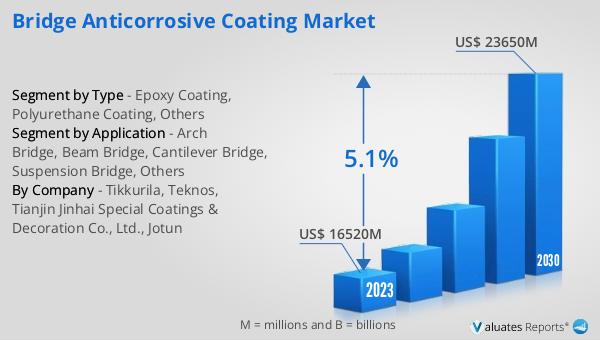

Global Bridge Anticorrosive Coating Market Outlook:

The global Bridge Anticorrosive Coating market was valued at US$ 16,520 million in 2023 and is anticipated to reach US$ 23,650 million by 2030, witnessing a compound annual growth rate (CAGR) of 5.1% during the forecast period from 2024 to 2030. This market growth reflects the increasing demand for durable and effective coatings to protect bridge structures from corrosion and extend their lifespan. The rising investments in infrastructure development and maintenance, coupled with the need to ensure the safety and reliability of bridges, are key factors driving this market. The market encompasses a wide range of coating types, each designed to meet specific requirements and environmental conditions. The ongoing advancements in coating technology, including the development of more sustainable and high-performance products, are expected to further fuel market growth. The Global Bridge Anticorrosive Coating Market is poised for significant expansion, driven by the critical need to protect and maintain the world's bridge infrastructure.

| Report Metric | Details |

| Report Name | Bridge Anticorrosive Coating Market |

| Accounted market size in 2023 | US$ 16520 million |

| Forecasted market size in 2030 | US$ 23650 million |

| CAGR | 5.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tikkurila, Teknos, Tianjin Jinhai Special Coatings & Decoration Co., Ltd., Jotun |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |