What is Global Bottom Sealing Bags Making Machine Market?

The global Bottom Sealing Bags Making Machine market is a specialized segment within the broader packaging machinery industry. These machines are designed to produce bags with a sealed bottom, which are commonly used for packaging a variety of products. The market for these machines is driven by the increasing demand for efficient and reliable packaging solutions across various industries. Bottom sealing bags are preferred because they offer superior strength and durability, making them ideal for heavy-duty applications. The machines used to produce these bags come in various configurations, including fully automatic and semi-automatic models, to cater to different production needs and scales. The market is characterized by technological advancements, which have led to the development of more efficient and user-friendly machines. Additionally, the growing emphasis on sustainability and eco-friendly packaging solutions is also influencing the market, as manufacturers seek to produce bags that are not only functional but also environmentally responsible. Overall, the global Bottom Sealing Bags Making Machine market is poised for steady growth, driven by the increasing demand for high-quality packaging solutions across various sectors.

Fully Automatic, Semi-Automatic in the Global Bottom Sealing Bags Making Machine Market:

Fully automatic and semi-automatic bottom sealing bags making machines are two primary types of equipment used in the global market, each offering distinct advantages and catering to different production needs. Fully automatic machines are designed to operate with minimal human intervention, making them ideal for large-scale production environments where efficiency and speed are paramount. These machines are equipped with advanced features such as automated feeding, cutting, sealing, and stacking, which significantly reduce the need for manual labor and increase production throughput. The integration of sophisticated control systems and sensors ensures precise and consistent bag production, minimizing waste and enhancing overall product quality. On the other hand, semi-automatic machines require some level of human intervention, particularly in the feeding and stacking processes. While they may not match the speed and efficiency of fully automatic machines, semi-automatic models offer greater flexibility and are often more cost-effective, making them suitable for small to medium-sized enterprises or production runs with varying requirements. These machines allow operators to make adjustments and control specific aspects of the production process, providing a balance between automation and manual oversight. Both types of machines are designed to handle a wide range of materials, including polyethylene, polypropylene, and biodegradable films, catering to the diverse needs of different industries. The choice between fully automatic and semi-automatic machines depends on various factors, including production volume, budget, and specific application requirements. Fully automatic machines are typically favored in high-volume production settings where speed and consistency are critical, while semi-automatic machines are preferred in scenarios where flexibility and cost considerations are more important. As technology continues to evolve, both types of machines are expected to incorporate more advanced features, such as improved energy efficiency, enhanced user interfaces, and greater adaptability to different materials and bag designs. This ongoing innovation will further drive the adoption of bottom sealing bags making machines across various sectors, contributing to the overall growth of the market.

Industrial, Agriculture, Manufacturing, Food Industry, Others in the Global Bottom Sealing Bags Making Machine Market:

The global Bottom Sealing Bags Making Machine market finds extensive usage across various sectors, including industrial, agriculture, manufacturing, and the food industry, among others. In the industrial sector, these machines are used to produce heavy-duty bags that can withstand the rigors of transporting and storing bulk materials such as chemicals, construction materials, and machinery parts. The strength and durability of bottom-sealed bags make them ideal for these applications, ensuring that the contents are securely contained and protected from damage. In agriculture, bottom sealing bags are commonly used for packaging seeds, fertilizers, and other agricultural products. The ability to produce bags in different sizes and materials allows farmers and agricultural businesses to choose the most suitable packaging solutions for their specific needs, enhancing the efficiency of storage and transportation. In the manufacturing sector, these machines are used to produce bags for packaging a wide range of products, from small components to large assemblies. The versatility of bottom sealing bags makes them suitable for various manufacturing applications, providing reliable and cost-effective packaging solutions. The food industry is another major user of bottom sealing bags making machines, as these bags are ideal for packaging a variety of food products, including grains, snacks, and frozen foods. The ability to produce bags with airtight seals helps to preserve the freshness and quality of the food, extending its shelf life and ensuring that it reaches consumers in optimal condition. Additionally, the market also caters to other sectors, such as retail and healthcare, where bottom sealing bags are used for packaging a diverse range of products. The growing demand for sustainable and eco-friendly packaging solutions is also driving the adoption of bottom sealing bags made from biodegradable and recyclable materials, further expanding the market's reach. Overall, the versatility and reliability of bottom sealing bags making machines make them indispensable across various industries, contributing to the efficient and secure packaging of a wide range of products.

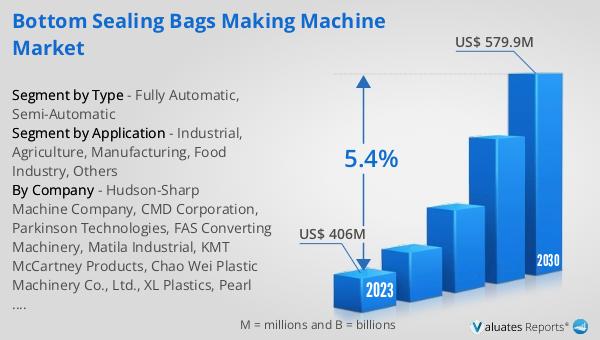

Global Bottom Sealing Bags Making Machine Market Outlook:

The global Bottom Sealing Bags Making Machine market was valued at US$ 406 million in 2023 and is anticipated to reach US$ 579.9 million by 2030, witnessing a CAGR of 5.4% during the forecast period from 2024 to 2030. This growth trajectory underscores the increasing demand for efficient and reliable packaging solutions across various industries. The market's expansion is driven by several factors, including technological advancements, the growing emphasis on sustainability, and the rising need for high-quality packaging in sectors such as food, agriculture, and manufacturing. As businesses continue to seek innovative and cost-effective packaging solutions, the demand for bottom sealing bags making machines is expected to rise, contributing to the market's steady growth. The adoption of these machines is also influenced by the need for improved production efficiency and the ability to produce bags with superior strength and durability. As a result, manufacturers are investing in advanced machinery that can meet the evolving needs of different industries, further propelling the market's growth. Overall, the global Bottom Sealing Bags Making Machine market is poised for significant expansion, driven by the increasing demand for high-quality and sustainable packaging solutions.

| Report Metric | Details |

| Report Name | Bottom Sealing Bags Making Machine Market |

| Accounted market size in 2023 | US$ 406 million |

| Forecasted market size in 2030 | US$ 579.9 million |

| CAGR | 5.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hudson-Sharp Machine Company, CMD Corporation, Parkinson Technologies, FAS Converting Machinery, Matila Industrial, KMT McCartney Products, Chao Wei Plastic Machinery Co., Ltd., XL Plastics, Pearl Engineering Company, Penta Machinery, Mamata Machinery, Wuxi HuaMao Plastics Co., Ltd.: |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |