What is Global 3D Factory Simulation Software Market?

The Global 3D Factory Simulation Software Market is a rapidly evolving sector that focuses on the use of advanced software to create virtual models of factory environments. This technology allows manufacturers to simulate and analyze various production processes in a three-dimensional space, providing valuable insights into efficiency, productivity, and potential bottlenecks. By using 3D factory simulation software, companies can visualize their entire production line, test different scenarios, and make data-driven decisions to optimize operations. This market is driven by the increasing demand for automation, the need for cost reduction, and the desire to improve overall production quality. The software is used across various industries, including manufacturing, logistics, automotive, food and beverage, aerospace, and defense, among others. As businesses continue to seek ways to enhance their operational efficiency and reduce downtime, the adoption of 3D factory simulation software is expected to grow, making it a crucial tool for modern industrial operations.

Cloud-based, On-premise in the Global 3D Factory Simulation Software Market:

In the Global 3D Factory Simulation Software Market, there are two primary deployment models: cloud-based and on-premise. Cloud-based solutions are hosted on remote servers and accessed via the internet, offering several advantages such as scalability, flexibility, and reduced upfront costs. These solutions allow companies to access the software from anywhere, making it ideal for businesses with multiple locations or remote teams. Cloud-based 3D factory simulation software also benefits from regular updates and maintenance provided by the service provider, ensuring that users always have access to the latest features and improvements. Additionally, cloud solutions often come with robust security measures to protect sensitive data, although some companies may still have concerns about data privacy and control. On the other hand, on-premise solutions are installed and run on a company's local servers and infrastructure. This deployment model offers greater control over the software and data, which can be crucial for businesses with strict security and compliance requirements. On-premise solutions can be customized to meet specific needs and integrated with existing systems, providing a tailored approach to factory simulation. However, this model typically involves higher upfront costs for hardware and software, as well as ongoing maintenance and support expenses. Companies opting for on-premise solutions must also ensure they have the necessary IT resources and expertise to manage the system effectively. Both cloud-based and on-premise 3D factory simulation software have their unique advantages and challenges. The choice between the two largely depends on a company's specific needs, budget, and IT capabilities. For instance, small to medium-sized enterprises (SMEs) with limited resources may prefer cloud-based solutions due to their lower initial investment and ease of use. In contrast, larger organizations with more complex requirements and stringent security standards might opt for on-premise solutions to maintain greater control over their data and systems. In conclusion, the Global 3D Factory Simulation Software Market offers a range of deployment options to suit different business needs. Cloud-based solutions provide flexibility, scalability, and cost-effectiveness, making them suitable for many companies. On-premise solutions, while requiring a higher initial investment, offer greater control and customization, making them ideal for businesses with specific security and compliance requirements. As the market continues to evolve, companies must carefully evaluate their needs and resources to choose the deployment model that best aligns with their operational goals and objectives.

Manufacturing, Logistics, Automobile, Food and Beverage, Aerospace and Defense, Others in the Global 3D Factory Simulation Software Market:

The usage of Global 3D Factory Simulation Software Market spans across various industries, each benefiting from the technology in unique ways. In manufacturing, 3D factory simulation software is used to design and optimize production lines, ensuring efficient use of resources and minimizing downtime. By simulating different production scenarios, manufacturers can identify potential bottlenecks and implement solutions before they become issues in the real world. This leads to improved productivity, reduced costs, and higher quality products. In the logistics sector, 3D factory simulation software helps in planning and optimizing warehouse layouts, material handling systems, and distribution networks. By creating virtual models of logistics operations, companies can test different strategies for inventory management, order fulfillment, and transportation, leading to more efficient and cost-effective operations. This technology also aids in identifying and mitigating risks, ensuring smooth and uninterrupted supply chain processes. The automotive industry leverages 3D factory simulation software to design and optimize assembly lines, ensuring that vehicles are produced efficiently and to the highest quality standards. By simulating the entire production process, automotive manufacturers can identify potential issues and make necessary adjustments, reducing the risk of costly errors and rework. This technology also supports the integration of new technologies and processes, such as automation and robotics, into the production line. In the food and beverage industry, 3D factory simulation software is used to design and optimize production processes, ensuring that products are manufactured efficiently and safely. By simulating different production scenarios, companies can identify potential issues and implement solutions to improve productivity and product quality. This technology also supports compliance with food safety regulations, helping companies to maintain high standards of hygiene and quality control. The aerospace and defense industry uses 3D factory simulation software to design and optimize complex production processes, ensuring that aircraft and defense systems are manufactured to the highest standards. By simulating different production scenarios, companies can identify potential issues and implement solutions to improve efficiency and reduce costs. This technology also supports the integration of new technologies and processes, such as advanced materials and manufacturing techniques, into the production line. Other industries, such as electronics, pharmaceuticals, and consumer goods, also benefit from the use of 3D factory simulation software. By creating virtual models of their production processes, companies can identify potential issues and implement solutions to improve efficiency, reduce costs, and enhance product quality. This technology supports the integration of new technologies and processes, helping companies to stay competitive in an increasingly complex and dynamic market. In summary, the Global 3D Factory Simulation Software Market is a versatile and valuable tool for a wide range of industries. By creating virtual models of production processes, companies can identify potential issues, implement solutions, and optimize operations, leading to improved efficiency, reduced costs, and higher quality products. As businesses continue to seek ways to enhance their operational efficiency and stay competitive, the adoption of 3D factory simulation software is expected to grow across various sectors.

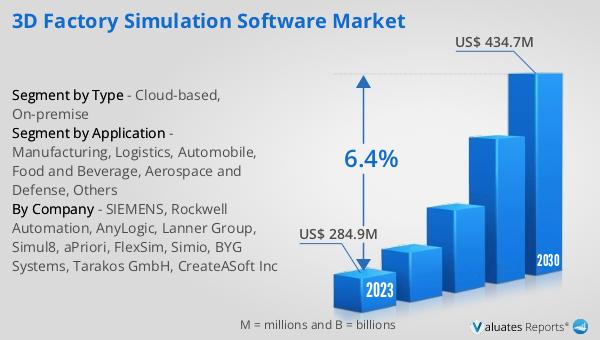

Global 3D Factory Simulation Software Market Outlook:

The global 3D Factory Simulation Software market was valued at US$ 284.9 million in 2023 and is anticipated to reach US$ 434.7 million by 2030, witnessing a CAGR of 6.4% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for advanced simulation tools that help businesses optimize their production processes and improve overall efficiency. The market's expansion is driven by the need for cost reduction, enhanced productivity, and the integration of new technologies into manufacturing and logistics operations. As companies across various industries recognize the benefits of 3D factory simulation software, the adoption of these tools is expected to rise, contributing to the market's steady growth. The software's ability to create detailed virtual models of factory environments allows businesses to test different scenarios, identify potential issues, and implement solutions before they impact real-world operations. This proactive approach not only saves time and resources but also ensures higher quality and more reliable production processes. As a result, the global 3D Factory Simulation Software market is poised for significant growth in the coming years, driven by the continuous advancements in technology and the increasing focus on operational efficiency.

| Report Metric | Details |

| Report Name | 3D Factory Simulation Software Market |

| Accounted market size in 2023 | US$ 284.9 million |

| Forecasted market size in 2030 | US$ 434.7 million |

| CAGR | 6.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | SIEMENS, Rockwell Automation, AnyLogic, Lanner Group, Simul8, aPriori, FlexSim, Simio, BYG Systems, Tarakos GmbH, CreateASoft Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |