What is Global Liposomes and Lipid Nanoparticles Pharmaceutical Reagents Market?

The Global Liposomes and Lipid Nanoparticles Pharmaceutical Reagents Market is a specialized segment within the broader pharmaceutical industry, focusing on the development and application of liposomes and lipid nanoparticles as carriers for drug delivery. These tiny, spherical vesicles are composed of lipid bilayers, which can encapsulate both hydrophilic and hydrophobic drugs, enhancing their stability and bioavailability. Liposomes and lipid nanoparticles are particularly valuable in the pharmaceutical field because they can improve the therapeutic index of drugs, reduce toxicity, and enable targeted delivery to specific tissues or cells. This market is driven by the increasing demand for advanced drug delivery systems, the rising prevalence of chronic diseases, and the growing interest in personalized medicine. As research and development in this area continue to advance, the market is expected to expand, offering innovative solutions for drug formulation and delivery. The versatility and efficacy of liposomes and lipid nanoparticles make them a promising area of exploration for pharmaceutical companies aiming to enhance the effectiveness of their products and meet the evolving needs of healthcare providers and patients worldwide.

DOTAP, DPPG-NA, DLPC, DSPE, Others in the Global Liposomes and Lipid Nanoparticles Pharmaceutical Reagents Market:

DOTAP, DPPG-NA, DLPC, DSPE, and other reagents are integral components of the Global Liposomes and Lipid Nanoparticles Pharmaceutical Reagents Market, each playing a unique role in the formulation and functionality of lipid-based drug delivery systems. DOTAP, or 1,2-dioleoyl-3-trimethylammonium-propane, is a cationic lipid commonly used in the preparation of liposomes for gene delivery. Its positive charge facilitates the binding of negatively charged nucleic acids, enhancing the efficiency of gene transfection. This makes DOTAP a valuable tool in gene therapy and vaccine development, where precise delivery of genetic material is crucial. DPPG-NA, or 1,2-dipalmitoyl-sn-glycero-3-phospho-(1'-rac-glycerol) sodium salt, is an anionic phospholipid that contributes to the stability and structural integrity of liposomes. It is often used in combination with other lipids to create stable liposomal formulations that can encapsulate a wide range of therapeutic agents. DLPC, or 1,2-dilauroyl-sn-glycero-3-phosphocholine, is a phospholipid that forms the structural backbone of liposomes. Its role is to provide a biocompatible and biodegradable matrix for drug encapsulation, ensuring that the liposomes can safely deliver their payload to target sites within the body. DSPE, or 1,2-distearoyl-sn-glycero-3-phosphoethanolamine, is another phospholipid that is often modified with polyethylene glycol (PEG) to create PEGylated liposomes. PEGylation enhances the circulation time of liposomes in the bloodstream by reducing their recognition and clearance by the immune system. This modification is particularly important for the delivery of drugs that require prolonged exposure to achieve therapeutic effects. In addition to these specific reagents, the market also includes a variety of other lipids and surfactants that can be tailored to meet the specific needs of different drug delivery applications. These components can be customized to optimize the size, charge, and release profile of liposomes and lipid nanoparticles, enabling the development of highly specialized drug delivery systems. The versatility of these reagents allows for the creation of liposomal formulations that can address a wide range of therapeutic challenges, from improving the solubility of poorly water-soluble drugs to enhancing the targeting of specific tissues or cells. As research in this field continues to evolve, the development of new and improved lipid reagents will play a critical role in advancing the capabilities of liposomal and lipid nanoparticle-based drug delivery systems.

Drug Discovery, Basic Research, Others in the Global Liposomes and Lipid Nanoparticles Pharmaceutical Reagents Market:

The Global Liposomes and Lipid Nanoparticles Pharmaceutical Reagents Market plays a crucial role in various areas of pharmaceutical research and development, including drug discovery, basic research, and other specialized applications. In drug discovery, liposomes and lipid nanoparticles are used as tools to enhance the delivery and efficacy of new therapeutic compounds. By encapsulating drugs within lipid-based carriers, researchers can improve the solubility, stability, and bioavailability of potential drug candidates, increasing their chances of success in preclinical and clinical trials. This is particularly important for drugs that have poor water solubility or are rapidly metabolized in the body, as liposomal encapsulation can help overcome these challenges and enable more effective drug delivery. In basic research, liposomes and lipid nanoparticles are used as model systems to study the behavior of biological membranes and the interactions between lipids and proteins. These studies provide valuable insights into the fundamental mechanisms of cellular processes, such as membrane fusion, signal transduction, and transport across cell membranes. By using liposomes as simplified models of cell membranes, researchers can investigate the effects of different lipid compositions, membrane curvature, and other factors on membrane dynamics and function. This knowledge can inform the design of more effective drug delivery systems and contribute to our understanding of various diseases and disorders. Beyond drug discovery and basic research, liposomes and lipid nanoparticles are also used in a variety of other applications, such as vaccine development, gene therapy, and diagnostic imaging. In vaccine development, liposomes can serve as adjuvants to enhance the immune response to antigens, improving the efficacy of vaccines against infectious diseases and cancer. In gene therapy, lipid nanoparticles are used to deliver nucleic acids, such as DNA and RNA, to target cells, enabling the correction of genetic defects or the modulation of gene expression. In diagnostic imaging, liposomes can be loaded with contrast agents to improve the visualization of tissues and organs in medical imaging techniques, such as MRI and CT scans. The versatility and adaptability of liposomes and lipid nanoparticles make them valuable tools in a wide range of pharmaceutical and biomedical applications, driving innovation and progress in the field.

Global Liposomes and Lipid Nanoparticles Pharmaceutical Reagents Market Outlook:

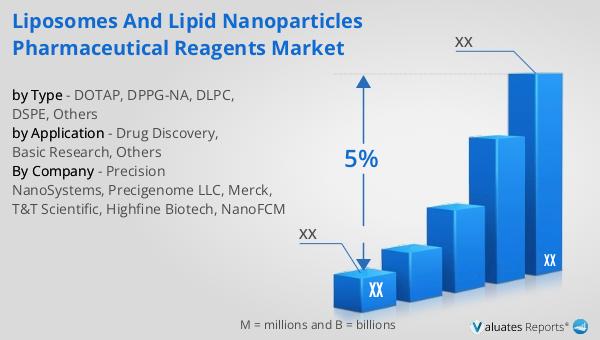

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, and it is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. This growth reflects the increasing demand for innovative and effective healthcare solutions worldwide. In comparison, the chemical drug market has shown a steady increase, with its value rising from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth in the chemical drug market highlights the ongoing importance of traditional pharmaceuticals, even as the industry continues to explore new frontiers in drug delivery and personalized medicine. The expansion of both the overall pharmaceutical market and the chemical drug segment underscores the dynamic nature of the industry, driven by advancements in research and development, regulatory approvals, and the introduction of new therapies. As the market continues to evolve, the integration of cutting-edge technologies, such as liposomes and lipid nanoparticles, will play a pivotal role in shaping the future of drug development and delivery. These innovations offer the potential to enhance the efficacy and safety of pharmaceutical products, ultimately improving patient outcomes and addressing unmet medical needs.

| Report Metric | Details |

| Report Name | Liposomes and Lipid Nanoparticles Pharmaceutical Reagents Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Precision NanoSystems, Precigenome LLC, Merck, T&T Scientific, Highfine Biotech, NanoFCM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |