What is Global Laser Calibration System Market?

The Global Laser Calibration System Market is a specialized sector within the broader field of precision measurement and instrumentation. Laser calibration systems are essential tools used to ensure the accuracy and precision of various equipment and machinery across different industries. These systems utilize laser technology to measure and adjust the performance of machines, ensuring they operate within specified tolerances. The market for these systems is driven by the increasing demand for high-precision manufacturing processes, where even the slightest deviation can lead to significant quality issues. Industries such as aerospace, automotive, electronics, and healthcare rely heavily on laser calibration systems to maintain the integrity of their production processes. As technology advances, the capabilities of laser calibration systems continue to improve, offering more accurate and efficient solutions. This market is characterized by continuous innovation, with companies investing in research and development to enhance the performance and functionality of their products. The global reach of this market is expanding as more industries recognize the importance of precision in their operations, leading to increased adoption of laser calibration systems worldwide.

Portable, Desktop in the Global Laser Calibration System Market:

In the Global Laser Calibration System Market, there are two primary types of systems: portable and desktop-based. Portable laser calibration systems are designed for flexibility and ease of use, allowing technicians to perform calibration tasks in various locations without the need for a fixed setup. These systems are compact, lightweight, and often battery-operated, making them ideal for fieldwork or situations where mobility is crucial. They are commonly used in industries such as construction, where equipment needs to be calibrated on-site to ensure accuracy in measurements and alignments. Portable systems are also favored in maintenance and repair operations, where quick and efficient calibration can minimize downtime and improve productivity. On the other hand, desktop-based laser calibration systems are typically more robust and offer higher precision and functionality. These systems are designed for use in controlled environments, such as laboratories or manufacturing facilities, where they can be integrated into existing workflows. Desktop systems often feature advanced software and hardware components, providing detailed analysis and reporting capabilities. They are ideal for applications that require high levels of accuracy and repeatability, such as in the production of semiconductors or aerospace components. The choice between portable and desktop-based systems depends on the specific needs of the user, with each offering distinct advantages. Portable systems provide convenience and flexibility, while desktop systems offer superior precision and functionality. As the demand for precision measurement continues to grow, both types of systems are expected to see increased adoption across various industries. Companies in the laser calibration system market are continually innovating to enhance the capabilities of their products, ensuring they meet the evolving needs of their customers. This includes the development of hybrid systems that combine the portability of handheld devices with the advanced features of desktop systems, providing users with the best of both worlds. The market for laser calibration systems is highly competitive, with numerous players offering a wide range of products to cater to different applications and industries. As technology advances, the distinction between portable and desktop systems is becoming less pronounced, with many systems now offering similar levels of precision and functionality. This trend is expected to continue as manufacturers strive to provide versatile solutions that can meet the diverse needs of their customers. Overall, the Global Laser Calibration System Market is poised for growth as industries increasingly recognize the importance of precision in their operations. Whether portable or desktop-based, laser calibration systems play a crucial role in ensuring the accuracy and reliability of equipment and machinery, ultimately contributing to improved quality and efficiency in various sectors.

Aerospace and Defense, Electronics and Semiconductors, Others in the Global Laser Calibration System Market:

The Global Laser Calibration System Market finds significant applications in various industries, including aerospace and defense, electronics and semiconductors, and others. In the aerospace and defense sector, laser calibration systems are crucial for maintaining the precision and accuracy of equipment and components. The aerospace industry demands high levels of precision due to the critical nature of its applications, where even minor deviations can have significant consequences. Laser calibration systems are used to ensure that components such as engines, navigation systems, and structural parts meet stringent quality standards. In defense, these systems are employed to calibrate weapons systems, radar equipment, and other critical technologies, ensuring they operate with the highest level of accuracy. In the electronics and semiconductor industry, laser calibration systems play a vital role in the production and testing of components. The manufacturing of semiconductors requires extreme precision, as even the smallest error can lead to defective products. Laser calibration systems are used to align and calibrate equipment used in the production process, ensuring that components are manufactured to exact specifications. These systems are also used in the testing phase, where they help verify the performance and reliability of electronic components. The demand for laser calibration systems in this industry is driven by the increasing complexity of electronic devices and the need for high-quality components. Beyond aerospace, defense, and electronics, laser calibration systems are used in a variety of other industries. In the automotive sector, they are employed to calibrate manufacturing equipment and ensure the precision of components such as engines and transmissions. In healthcare, laser calibration systems are used to maintain the accuracy of medical devices and equipment, ensuring they provide reliable results. The construction industry also benefits from these systems, using them to calibrate tools and equipment for accurate measurements and alignments. The versatility of laser calibration systems makes them valuable tools across a wide range of applications, contributing to improved quality and efficiency in various sectors. As industries continue to prioritize precision and accuracy, the demand for laser calibration systems is expected to grow, driving innovation and development in this market.

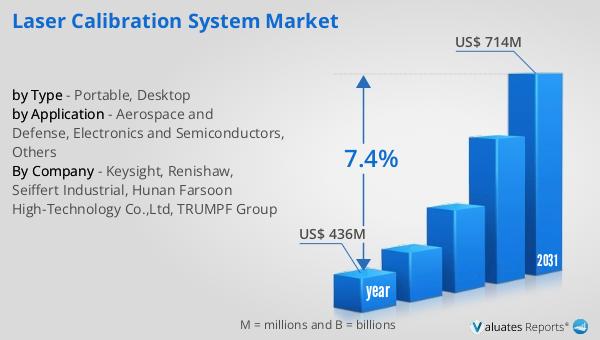

Global Laser Calibration System Market Outlook:

The outlook for the Global Laser Calibration System Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $436 million. By 2031, it is anticipated to expand significantly, reaching an estimated value of $714 million. This growth is expected to occur at a compound annual growth rate (CAGR) of 7.4% over the forecast period. This upward trend reflects the increasing demand for precision measurement solutions across various industries. As technology continues to advance, the capabilities of laser calibration systems are expected to improve, offering more accurate and efficient solutions. The market's expansion is driven by the growing recognition of the importance of precision in manufacturing and other sectors. Industries such as aerospace, automotive, electronics, and healthcare are increasingly relying on laser calibration systems to ensure the accuracy and reliability of their equipment and processes. This demand is further fueled by the need for high-quality products and the desire to minimize errors and defects. As a result, the Global Laser Calibration System Market is poised for substantial growth, with companies investing in research and development to enhance the performance and functionality of their products. The market's positive outlook is a testament to the critical role that laser calibration systems play in ensuring precision and accuracy across various applications.

| Report Metric | Details |

| Report Name | Laser Calibration System Market |

| Accounted market size in year | US$ 436 million |

| Forecasted market size in 2031 | US$ 714 million |

| CAGR | 7.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Keysight, Renishaw, Seiffert Industrial, Hunan Farsoon High-Technology Co.,Ltd, TRUMPF Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |