What is Global Vertical Furnace Equipment Market?

The Global Vertical Furnace Equipment Market refers to the industry focused on the production and distribution of vertical furnace systems used primarily in semiconductor manufacturing. These furnaces are essential for processes such as oxidation, diffusion, and annealing, which are critical steps in the fabrication of integrated circuits and other semiconductor devices. Vertical furnaces are preferred in many applications due to their ability to handle multiple wafers simultaneously, offering high throughput and uniform processing. The market is driven by the increasing demand for semiconductors across various sectors, including consumer electronics, automotive, and telecommunications. As technology advances, the need for more efficient and precise manufacturing equipment grows, propelling the demand for vertical furnace equipment. Companies in this market are continually innovating to improve the performance and efficiency of their products, catering to the evolving needs of semiconductor manufacturers. The market's growth is also influenced by the expansion of semiconductor manufacturing facilities worldwide, particularly in regions like Asia-Pacific, which is a hub for electronics production. Overall, the Global Vertical Furnace Equipment Market plays a crucial role in supporting the semiconductor industry's growth and technological advancements.

200mm and Below, 300mm in the Global Vertical Furnace Equipment Market:

In the Global Vertical Furnace Equipment Market, wafer sizes are a critical factor, with 200mm and below, and 300mm being the primary categories. The 200mm and below category includes wafers that are typically used in mature semiconductor processes. These wafers are prevalent in the production of devices that do not require the latest technology nodes, such as power management ICs, analog devices, and certain types of sensors. The demand for 200mm wafers remains steady due to their cost-effectiveness and the continued need for legacy semiconductor devices. Vertical furnaces designed for 200mm and below wafers are optimized for these specific processes, ensuring efficient and uniform thermal treatment. On the other hand, the 300mm wafer category represents the more advanced segment of the market. These larger wafers are used in cutting-edge semiconductor manufacturing processes, where high-volume production and advanced technology nodes are required. The shift towards 300mm wafers is driven by the need for increased production efficiency and reduced costs per chip. Vertical furnaces for 300mm wafers are designed to handle the complexities of modern semiconductor fabrication, offering precise control over temperature and atmospheric conditions. The transition from 200mm to 300mm wafers is a significant trend in the semiconductor industry, as manufacturers seek to optimize their production capabilities and meet the growing demand for advanced electronic devices. This shift also reflects the industry's move towards more sophisticated and miniaturized semiconductor components, which require the precision and scalability offered by 300mm wafer processing. As the Global Vertical Furnace Equipment Market evolves, manufacturers are investing in research and development to enhance the capabilities of their equipment, ensuring they can meet the diverse needs of both 200mm and 300mm wafer processing. This includes innovations in furnace design, materials, and process control technologies, which are essential for maintaining competitiveness in a rapidly changing market. The ability to efficiently process both 200mm and 300mm wafers is crucial for companies operating in this space, as it allows them to cater to a broad range of customer requirements and capitalize on the opportunities presented by the ongoing evolution of the semiconductor industry.

Integrated Circuit, MEMS in the Global Vertical Furnace Equipment Market:

The Global Vertical Furnace Equipment Market finds significant applications in the production of Integrated Circuits (ICs) and Micro-Electro-Mechanical Systems (MEMS). In the realm of Integrated Circuits, vertical furnaces are indispensable for several critical processes. These include oxidation, where a layer of silicon dioxide is grown on the wafer surface, and diffusion, which involves the introduction of dopants to modify the electrical properties of the silicon. Vertical furnaces are also used for annealing, a process that repairs damage to the silicon lattice and activates dopants. The precision and uniformity offered by vertical furnaces are crucial for ensuring the performance and reliability of ICs, which are the building blocks of modern electronics. As the demand for smaller, faster, and more efficient ICs grows, the role of vertical furnace equipment becomes increasingly important. In the case of MEMS, vertical furnaces are used in similar processes, such as oxidation and annealing, but with additional considerations for the unique structures and materials involved in MEMS fabrication. MEMS devices, which combine mechanical and electrical components at a microscale, are used in a wide range of applications, from automotive sensors to medical devices. The ability to precisely control the thermal processes in MEMS fabrication is essential for achieving the desired mechanical and electrical properties. Vertical furnaces provide the necessary control and uniformity, enabling the production of high-quality MEMS devices. The Global Vertical Furnace Equipment Market is thus integral to the advancement of both IC and MEMS technologies, supporting the development of innovative electronic and electromechanical devices. As these technologies continue to evolve, the demand for advanced vertical furnace equipment is expected to grow, driving further innovation and investment in this critical area of semiconductor manufacturing.

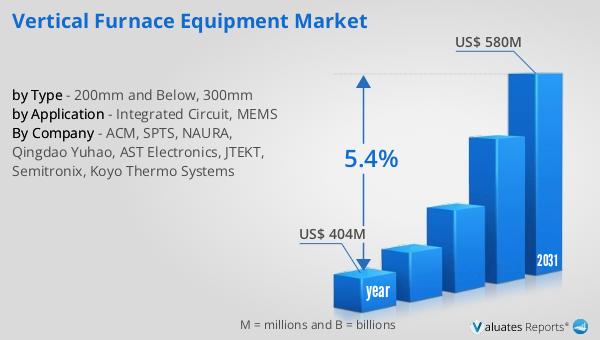

Global Vertical Furnace Equipment Market Outlook:

The global market for Vertical Furnace Equipment was valued at approximately $404 million in 2024, with expectations to expand to around $580 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.4% over the forecast period. This growth trajectory underscores the increasing demand for vertical furnace systems, driven by advancements in semiconductor manufacturing and the rising need for efficient and precise processing equipment. The market is dominated by the top three companies, which collectively hold a significant share of over 73%, highlighting the competitive nature of the industry and the importance of innovation and technological leadership. China emerges as the largest market, accounting for about 37% of the global share, followed by Japan and North America, with shares of approximately 15% and 14%, respectively. This distribution indicates the strategic importance of the Asia-Pacific region in the semiconductor industry, given its robust manufacturing infrastructure and growing investments in technology development. The market dynamics are shaped by various factors, including technological advancements, the expansion of semiconductor fabrication facilities, and the increasing complexity of semiconductor devices. As the industry continues to evolve, companies operating in the Global Vertical Furnace Equipment Market are focusing on enhancing their product offerings and expanding their market presence to capitalize on the opportunities presented by the growing demand for advanced semiconductor manufacturing equipment.

| Report Metric | Details |

| Report Name | Vertical Furnace Equipment Market |

| Accounted market size in year | US$ 404 million |

| Forecasted market size in 2031 | US$ 580 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ACM, SPTS, NAURA, Qingdao Yuhao, AST Electronics, JTEKT, Semitronix, Koyo Thermo Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |