What is Global Dosing Mixer Market?

The Global Dosing Mixer Market is a specialized segment within the broader industrial equipment sector, focusing on devices designed to mix and dose various materials accurately. These mixers are essential in industries where precise measurement and mixing of components are crucial for product quality and consistency. The market encompasses a range of mixer types, each tailored to specific applications and materials, such as liquids, powders, and granules. The demand for dosing mixers is driven by the need for efficiency, accuracy, and automation in manufacturing processes. As industries strive to enhance productivity and reduce waste, the adoption of advanced dosing mixers becomes increasingly important. These mixers are equipped with sophisticated control systems that allow for precise adjustments and monitoring, ensuring optimal performance. The market is characterized by continuous innovation, with manufacturers developing new technologies to meet the evolving needs of various industries. As a result, the Global Dosing Mixer Market plays a vital role in supporting the operational efficiency and product quality of numerous sectors worldwide.

Pulp Type, Screw Type, Disc Turbine Type, Others in the Global Dosing Mixer Market:

In the Global Dosing Mixer Market, various types of mixers are utilized, each serving distinct purposes based on their design and functionality. The Pulp Type mixer is primarily used in industries where the mixing of fibrous materials is required. These mixers are designed to handle high-viscosity materials, ensuring that the fibers are evenly distributed throughout the mixture. They are commonly used in the paper and pulp industry, where the uniformity of the pulp is crucial for the quality of the final product. The Screw Type mixer, on the other hand, is designed for continuous mixing processes. It is particularly effective in handling bulk materials and is widely used in industries such as food processing and pharmaceuticals. The screw mechanism allows for consistent mixing and dosing, making it ideal for applications where precision is key. The Disc Turbine Type mixer is known for its versatility and efficiency in mixing low to medium viscosity liquids. It is often used in the chemical and water treatment industries, where rapid mixing and uniform distribution of components are essential. The design of the disc turbine allows for high shear mixing, which is beneficial in breaking down particles and ensuring a homogeneous mixture. Other types of mixers in the market include those designed for specific applications, such as static mixers and dynamic mixers. Static mixers are used for inline mixing processes, where the flow of materials is continuous, and no moving parts are involved. They are ideal for applications where low maintenance and energy efficiency are priorities. Dynamic mixers, on the other hand, involve moving parts and are used in applications where more intensive mixing is required. These mixers are often used in industries such as cosmetics and personal care, where the texture and consistency of the product are critical. Each type of mixer in the Global Dosing Mixer Market is designed to meet the specific needs of different industries, ensuring that the mixing process is efficient, accurate, and tailored to the materials being handled.

Chemical Industry, Pharmaceutical Industry, Product Industry, Water Treatment Industry, Others in the Global Dosing Mixer Market:

The Global Dosing Mixer Market finds extensive applications across various industries, each utilizing these mixers to enhance their production processes and product quality. In the Chemical Industry, dosing mixers are essential for the precise mixing of chemicals, ensuring that reactions occur under controlled conditions. This precision is crucial for the production of high-quality chemical products, where even minor deviations in composition can lead to significant differences in product performance. Dosing mixers in this industry are often equipped with advanced control systems that allow for real-time monitoring and adjustments, ensuring optimal mixing conditions. In the Pharmaceutical Industry, dosing mixers play a vital role in the formulation of medications. The accuracy and consistency provided by these mixers are essential for ensuring that each batch of medication meets stringent quality standards. This is particularly important in the production of drugs, where the correct dosage of active ingredients is critical for efficacy and safety. The Product Industry, which includes sectors such as food and beverage, cosmetics, and personal care, also relies heavily on dosing mixers. In these industries, the texture, flavor, and appearance of the final product are often dependent on the precise mixing of ingredients. Dosing mixers ensure that these components are evenly distributed, resulting in a consistent and high-quality product. In the Water Treatment Industry, dosing mixers are used to mix chemicals and additives into water to achieve desired treatment outcomes. This includes processes such as disinfection, pH adjustment, and coagulation, where precise dosing is essential for effective treatment. The use of dosing mixers in this industry helps to ensure that water treatment processes are efficient and that the treated water meets regulatory standards. Other industries that utilize dosing mixers include agriculture, where they are used for the precise mixing of fertilizers and pesticides, and the construction industry, where they are used in the preparation of concrete and other building materials. Across all these industries, the Global Dosing Mixer Market provides the tools necessary for efficient and accurate mixing, supporting the production of high-quality products and the achievement of desired outcomes.

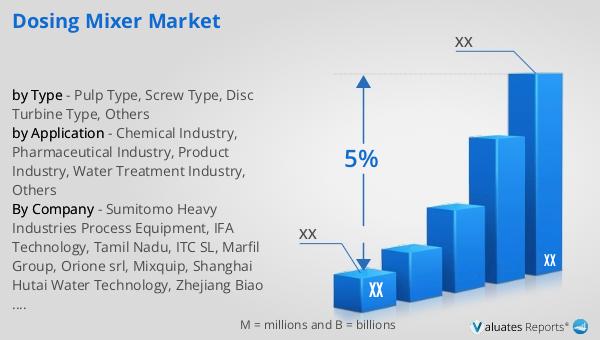

Global Dosing Mixer Market Outlook:

The outlook for the Global Dosing Mixer Market can be contextualized by examining the broader trends in related industries. For instance, the global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth trajectory highlights the increasing demand for pharmaceutical products, which in turn drives the need for precise and efficient dosing mixers in the industry. In comparison, the chemical drug market has shown a steady increase, growing from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth underscores the expanding scope of chemical manufacturing, where dosing mixers play a crucial role in ensuring the accurate mixing of chemical components. The demand for dosing mixers is closely linked to these industry trends, as they are integral to the production processes in both the pharmaceutical and chemical sectors. As these industries continue to grow and evolve, the need for advanced dosing mixers that can meet the demands of modern manufacturing processes becomes increasingly important. The Global Dosing Mixer Market is poised to benefit from these trends, providing the necessary equipment to support the efficient and accurate production of a wide range of products.

| Report Metric | Details |

| Report Name | Dosing Mixer Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sumitomo Heavy Industries Process Equipment, IFA Technology, Tamil Nadu, ITC SL, Marfil Group, Orione srl, Mixquip, Shanghai Hutai Water Technology, Zhejiang Biao Long Pump Technology, Changzhou Mingye Machinery, Jiangsu Ruke Environmental Protection Equipment, Yixing Mingyu Environmental Protection Technology, Jiangsu Joyal Environmental Protection, Chengdu Xinyuan Environmental Protection Equipment, Wuxi Zevui Environmental Protection Technology, Ningbo Yao Luo Mechanical & Electrical, Shanghai Qiyang Environmental Protection Electromechanical Equipment, Nanjing Linuo Water Treatment Equipment, Nanjing Lanjiang Water Treatment Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |