What is Global Industrial Shredding Machinery Market?

The Global Industrial Shredding Machinery Market is a dynamic and essential segment of the industrial equipment industry, focusing on machines designed to reduce the size of various materials through shredding. These machines are crucial for waste management, recycling, and material processing across numerous industries. Industrial shredders are used to process a wide range of materials, including metals, plastics, wood, and paper, transforming them into smaller, manageable pieces. This not only aids in recycling efforts but also helps in reducing waste volume, making disposal more efficient and environmentally friendly. The market for industrial shredding machinery is driven by the increasing need for efficient waste management solutions and the growing emphasis on recycling and sustainability. As industries continue to expand and the demand for raw materials rises, the role of shredding machinery becomes even more critical. These machines are available in various configurations, including single shaft, two shaft, and four shaft designs, each catering to specific shredding needs and material types. The market is characterized by technological advancements, with manufacturers focusing on developing more efficient, durable, and user-friendly shredding solutions to meet the diverse needs of industries worldwide.

Single Shaft, Two Shaft, Four Shaft, Others in the Global Industrial Shredding Machinery Market:

In the Global Industrial Shredding Machinery Market, different types of shredders are designed to meet specific industrial needs, with single shaft, two shaft, and four shaft shredders being the most common. Single shaft shredders are typically used for processing materials that require a consistent particle size. They feature a rotor with cutting blades that rotate at high speeds, effectively shredding materials like plastics, wood, and paper. These shredders are known for their simplicity and efficiency, making them ideal for applications where uniformity in output is crucial. Two shaft shredders, on the other hand, are designed for heavier-duty applications. They consist of two parallel shafts with interlocking blades that rotate in opposite directions. This design allows them to handle tougher materials such as metals and tires, making them suitable for industries dealing with bulky and dense waste. The interlocking blades ensure that materials are shredded into smaller pieces, facilitating easier handling and processing. Four shaft shredders take the shredding process a step further by incorporating two additional shafts. This design enhances the shredding capability, allowing for finer and more consistent output. Four shaft shredders are often used in applications where precise particle size is required, such as in the recycling of electronic waste and other complex materials. They offer superior performance in terms of throughput and efficiency, making them a preferred choice for industries with high-volume shredding needs. In addition to these, there are other specialized shredders designed for specific applications, such as granulators and grinders, which further diversify the market. Each type of shredder offers unique advantages, catering to the diverse requirements of industries ranging from waste management to manufacturing. As the demand for efficient and sustainable waste processing solutions continues to grow, the Global Industrial Shredding Machinery Market is expected to evolve, with manufacturers focusing on innovation and customization to meet the ever-changing needs of their clients.

MSW Recycling, WEEE Recycling, Paper Recycling, Wood Recycling, Scrap Metal Recycling, Others in the Global Industrial Shredding Machinery Market:

The Global Industrial Shredding Machinery Market plays a pivotal role in various recycling and waste management applications, including MSW (Municipal Solid Waste) Recycling, WEEE (Waste Electrical and Electronic Equipment) Recycling, Paper Recycling, Wood Recycling, and Scrap Metal Recycling. In MSW Recycling, shredders are used to reduce the volume of municipal waste, making it easier to handle and process. By breaking down waste into smaller pieces, shredders facilitate the separation of recyclable materials from non-recyclable ones, enhancing the efficiency of recycling operations. In WEEE Recycling, shredders are essential for processing electronic waste, which often contains valuable metals and components. Shredding electronic waste allows for the recovery of precious metals and the safe disposal of hazardous materials, contributing to environmental sustainability. Paper Recycling is another area where shredding machinery is indispensable. Shredders are used to process waste paper, breaking it down into smaller pieces that can be easily pulped and recycled into new paper products. This not only conserves natural resources but also reduces the environmental impact of paper production. Wood Recycling involves the shredding of wood waste, such as pallets, construction debris, and tree branches, into smaller pieces that can be used as biomass fuel or raw material for new wood products. Shredders play a crucial role in transforming wood waste into valuable resources, supporting the circular economy. Scrap Metal Recycling is another critical application of shredding machinery. Shredders are used to process metal waste, such as old vehicles, appliances, and industrial scrap, into smaller pieces that can be easily melted and recycled into new metal products. This not only conserves natural resources but also reduces the energy consumption and environmental impact of metal production. In addition to these applications, shredders are also used in other areas, such as plastic recycling and rubber recycling, further highlighting their versatility and importance in the global recycling industry. As the demand for sustainable waste management solutions continues to grow, the Global Industrial Shredding Machinery Market is expected to expand, with manufacturers focusing on developing more efficient and environmentally friendly shredding technologies.

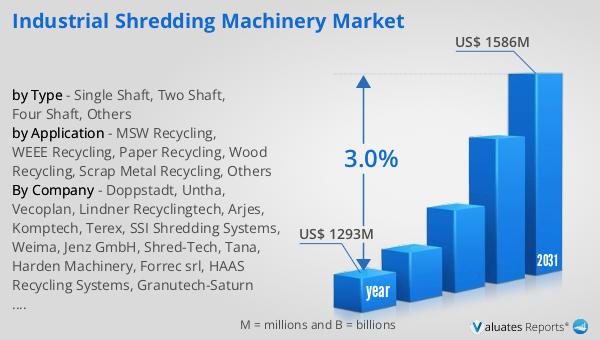

Global Industrial Shredding Machinery Market Outlook:

The global market for industrial shredding machinery was valued at approximately $1,293 million in 2024. This market is anticipated to grow steadily, reaching an estimated size of $1,586 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.0% over the forecast period. This steady increase in market size reflects the rising demand for efficient waste management and recycling solutions across various industries. As environmental concerns continue to mount, industries are increasingly turning to shredding machinery to help manage waste and promote sustainability. The growth in this market is driven by several factors, including technological advancements in shredding machinery, the increasing emphasis on recycling and resource conservation, and the need for efficient waste processing solutions. Manufacturers are focusing on developing more efficient, durable, and user-friendly shredding machines to meet the diverse needs of industries worldwide. As the market continues to evolve, it is expected to witness further innovations and advancements, with manufacturers striving to offer more customized and sustainable shredding solutions. This growth in the Global Industrial Shredding Machinery Market underscores the critical role that shredding machinery plays in promoting sustainability and resource conservation in today's industrial landscape.

| Report Metric | Details |

| Report Name | Industrial Shredding Machinery Market |

| Accounted market size in year | US$ 1293 million |

| Forecasted market size in 2031 | US$ 1586 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Doppstadt, Untha, Vecoplan, Lindner Recyclingtech, Arjes, Komptech, Terex, SSI Shredding Systems, Weima, Jenz GmbH, Shred-Tech, Tana, Harden Machinery, Forrec srl, HAAS Recycling Systems, Granutech-Saturn Systems, ZERMA, Allegheny, Genox, Cresswood, Erdwich, William |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |