What is Global Permanent Magnet Variable Frequency Centrifugal Blower Market?

The Global Permanent Magnet Variable Frequency Centrifugal Blower Market is a specialized segment within the broader industrial machinery sector. These blowers are designed to provide efficient air movement by utilizing permanent magnets and variable frequency drives, which allow for precise control over the blower's speed and power consumption. This technology is particularly advantageous in applications requiring consistent airflow and pressure, as it can adapt to varying operational demands while maintaining energy efficiency. The use of permanent magnets reduces mechanical friction, leading to lower noise and vibration levels, which in turn extends the service life of the equipment. Additionally, these blowers are known for their ability to save more than 30% of energy compared to traditional blowers, making them an attractive option for industries looking to reduce operational costs and environmental impact. The market for these blowers is expanding globally, driven by increasing demand in sectors such as manufacturing, HVAC, and wastewater treatment, where efficient air handling is crucial. As industries continue to prioritize sustainability and cost-effectiveness, the adoption of permanent magnet variable frequency centrifugal blowers is expected to grow, offering significant benefits in terms of performance and energy savings.

37-100 KW, 100-200 KW, 200-300 KW, 300-400 KW, Above 400 KW in the Global Permanent Magnet Variable Frequency Centrifugal Blower Market:

In the Global Permanent Magnet Variable Frequency Centrifugal Blower Market, the power range of blowers is categorized into several segments, including 37-100 KW, 100-200 KW, 200-300 KW, 300-400 KW, and above 400 KW. Each of these categories serves different industrial needs based on the required airflow and pressure. The 37-100 KW segment is typically used in smaller industrial applications where moderate airflow is sufficient. These blowers are ideal for facilities that require efficient air movement without the need for high power consumption, making them suitable for small to medium-sized manufacturing plants or workshops. The 100-200 KW range caters to medium-sized operations, providing a balance between power and efficiency. These blowers are often found in industries such as food processing and pharmaceuticals, where precise air control is necessary for maintaining product quality and safety. Moving up the scale, the 200-300 KW blowers are designed for larger industrial applications, such as in the cement and building materials industry, where substantial airflow is required to manage dust and particulate matter. These blowers offer robust performance and are capable of handling more demanding environments. The 300-400 KW segment is tailored for even more intensive applications, providing high power output for large-scale operations. Industries such as paper-making and heavy manufacturing benefit from these blowers due to their ability to maintain consistent airflow under challenging conditions. Finally, blowers above 400 KW are used in the most demanding industrial settings, where maximum airflow and pressure are critical. These blowers are essential in large-scale facilities that require continuous and reliable air movement, such as in power plants and large chemical processing units. Across all these segments, the integration of permanent magnet and variable frequency technology ensures that the blowers operate with high efficiency, reduced energy consumption, and minimal environmental impact. This makes them a preferred choice for industries aiming to enhance operational efficiency while adhering to environmental regulations.

Paper-Making Industry, Cement and Building Materials Industry, Food Industry, Pharmaceutical Industry, Others in the Global Permanent Magnet Variable Frequency Centrifugal Blower Market:

The Global Permanent Magnet Variable Frequency Centrifugal Blower Market finds extensive usage across various industries due to its energy efficiency and adaptability. In the paper-making industry, these blowers are crucial for processes such as drying and ventilation. The ability to control airflow precisely ensures that paper products are dried uniformly, reducing the risk of defects and improving overall quality. Additionally, the energy-saving features of these blowers help paper mills reduce operational costs significantly. In the cement and building materials industry, these blowers play a vital role in managing dust and particulate emissions. The high airflow capacity of these blowers ensures that dust is effectively captured and removed, maintaining a clean and safe working environment. This is particularly important in cement production, where dust control is a major concern. The food industry also benefits from the use of these blowers, particularly in processes that require controlled environments, such as drying and packaging. The precise airflow control helps maintain product quality and safety, which is critical in food processing. In the pharmaceutical industry, these blowers are used in cleanrooms and other controlled environments where maintaining air purity is essential. The low noise and vibration levels of these blowers make them ideal for sensitive applications where equipment reliability and minimal disruption are paramount. Beyond these specific industries, the blowers are also used in various other applications, such as wastewater treatment and HVAC systems, where efficient air movement is necessary. The versatility and efficiency of permanent magnet variable frequency centrifugal blowers make them a valuable asset in any industry that requires reliable and cost-effective air handling solutions.

Global Permanent Magnet Variable Frequency Centrifugal Blower Market Outlook:

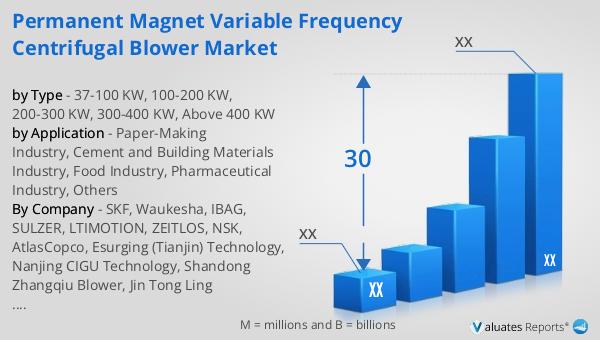

The market outlook for the Global Permanent Magnet Variable Frequency Centrifugal Blower Market highlights several key advantages that make these blowers an attractive choice for various industries. These blowers are designed to adapt to both positive and negative pressure fields, allowing them to function effectively in diverse operational environments. Their ability to start and stop frequently without experiencing significant mechanical wear is a notable benefit, as it reduces maintenance requirements and extends the equipment's lifespan. The low mechanical friction inherent in the design of these blowers contributes to their quiet operation, with reduced noise and vibration levels compared to traditional blowers. This not only enhances the working environment but also minimizes the risk of equipment failure. One of the most significant advantages of these blowers is their energy efficiency, with potential energy savings of more than 30% compared to conventional blowers. This makes them an appealing option for industries looking to reduce energy consumption and operational costs. In the North American market, the demand for permanent magnet variable frequency centrifugal blowers is expected to grow significantly. The market is projected to increase from its 2024 valuation to reach a higher value by 2031, driven by a compound annual growth rate (CAGR) during the forecast period from 2025 to 2031. This growth is indicative of the increasing recognition of the benefits these blowers offer in terms of performance, efficiency, and sustainability. As industries continue to prioritize energy efficiency and cost-effectiveness, the adoption of these advanced blower technologies is likely to expand, contributing to the overall growth of the market.

| Report Metric | Details |

| Report Name | Permanent Magnet Variable Frequency Centrifugal Blower Market |

| CAGR | 30 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SKF, Waukesha, IBAG, SULZER, LTIMOTION, ZEITLOS, NSK, AtlasCopco, Esurging (Tianjin) Technology, Nanjing CIGU Technology, Shandong Zhangqiu Blower, Jin Tong Ling Technology Group, Xi'an Shaangu Power, Shandong Tianrui Heavy Industry, Xinlei Compressor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |