What is Global Single Stand Reversing Cold Mill Market?

The Global Single Stand Reversing Cold Mill Market is a specialized segment within the broader industrial machinery sector, focusing on equipment used for cold rolling processes. Cold rolling is a metalworking process that involves the deformation of metal at room temperature to achieve a desired thickness and surface finish. The single stand reversing cold mill is a type of machinery that allows for the rolling of metal sheets in a back-and-forth manner, enhancing precision and control over the final product. This market is driven by the demand for high-quality metal sheets with specific mechanical properties, which are essential in various industries such as automotive, construction, and electronics. The equipment is designed to handle different types of metals, including steel, aluminum, and copper, making it versatile and adaptable to various industrial needs. The market's growth is influenced by technological advancements, increasing industrialization, and the need for energy-efficient and cost-effective manufacturing solutions. As industries continue to evolve, the demand for high-performance cold rolling mills is expected to rise, further propelling the market's expansion.

Four-roller Cold Rolling Mill, Six-roller Cold Rolling Mill, Others in the Global Single Stand Reversing Cold Mill Market:

The Global Single Stand Reversing Cold Mill Market encompasses various types of cold rolling mills, each designed to meet specific industrial requirements. Among these, the four-roller cold rolling mill is a widely used configuration. This type of mill consists of four rolls: two work rolls and two backup rolls. The work rolls are in direct contact with the metal sheet, applying the necessary pressure to achieve the desired thickness. The backup rolls provide additional support, ensuring stability and reducing the risk of deflection. This configuration is particularly effective for producing thin metal sheets with high precision and uniformity. The six-roller cold rolling mill, on the other hand, offers enhanced control and flexibility. It includes two additional intermediate rolls between the work rolls and backup rolls. These intermediate rolls help distribute the rolling force more evenly, reducing the load on the work rolls and minimizing the risk of defects. This setup is ideal for producing ultra-thin metal sheets with superior surface quality and dimensional accuracy. The six-roller mill is often used in applications where stringent quality standards are required, such as in the production of high-grade automotive components and electronic materials. In addition to the four-roller and six-roller configurations, the market also includes other types of cold rolling mills, each designed to address specific challenges and requirements. For instance, some mills are equipped with advanced automation and control systems, allowing for real-time monitoring and adjustment of rolling parameters. This ensures consistent product quality and reduces the likelihood of defects. Other mills may feature specialized roll materials or coatings to enhance durability and performance, particularly when working with hard or abrasive materials. The choice of mill configuration depends on various factors, including the type of metal being processed, the desired product specifications, and the production volume. Manufacturers in the Global Single Stand Reversing Cold Mill Market are continually innovating to develop more efficient and versatile equipment. This includes the integration of advanced technologies such as artificial intelligence and machine learning, which enable predictive maintenance and process optimization. By leveraging these technologies, manufacturers can enhance the performance and reliability of their mills, reducing downtime and operational costs. Furthermore, the market is witnessing a growing emphasis on sustainability and energy efficiency. Manufacturers are exploring ways to reduce the environmental impact of cold rolling processes, such as by optimizing energy consumption and minimizing waste. This aligns with the broader industry trend towards sustainable manufacturing practices and the increasing demand for eco-friendly products. Overall, the Global Single Stand Reversing Cold Mill Market is characterized by a diverse range of products and technologies, each designed to meet the evolving needs of modern industries. As manufacturers continue to innovate and adapt to changing market dynamics, the demand for high-performance cold rolling mills is expected to remain strong.

Automotive Industry, Medical Industry, Construction Industry, Others in the Global Single Stand Reversing Cold Mill Market:

The Global Single Stand Reversing Cold Mill Market plays a crucial role in various industries, providing essential equipment for the production of high-quality metal sheets. In the automotive industry, cold rolling mills are used to produce lightweight and durable components that meet stringent safety and performance standards. The ability to produce thin metal sheets with precise dimensions and superior surface quality is critical for automotive manufacturers, who are constantly seeking ways to improve fuel efficiency and reduce emissions. Cold rolling mills enable the production of high-strength steel and aluminum alloys, which are used in the construction of vehicle bodies, chassis, and other critical components. In the medical industry, the demand for high-quality metal sheets is driven by the need for precision and reliability in medical devices and equipment. Cold rolling mills are used to produce stainless steel and other biocompatible materials that are essential for the manufacture of surgical instruments, implants, and diagnostic equipment. The ability to produce ultra-thin metal sheets with exceptional surface finish and dimensional accuracy is crucial for ensuring the safety and effectiveness of medical products. In the construction industry, cold rolling mills are used to produce metal sheets and profiles that are used in a wide range of applications, from roofing and cladding to structural components. The ability to produce high-strength and corrosion-resistant materials is essential for ensuring the durability and longevity of construction projects. Cold rolling mills enable the production of galvanized steel and other coated materials that provide enhanced protection against environmental factors. In addition to these industries, the Global Single Stand Reversing Cold Mill Market serves a variety of other sectors, including electronics, aerospace, and consumer goods. In the electronics industry, cold rolling mills are used to produce thin metal foils and sheets that are used in the manufacture of circuit boards, connectors, and other components. The ability to produce materials with precise thickness and excellent electrical conductivity is critical for ensuring the performance and reliability of electronic devices. In the aerospace industry, cold rolling mills are used to produce lightweight and high-strength materials that are used in the construction of aircraft and spacecraft. The ability to produce materials with exceptional mechanical properties and resistance to extreme temperatures is essential for ensuring the safety and performance of aerospace applications. Overall, the Global Single Stand Reversing Cold Mill Market is characterized by its versatility and adaptability to a wide range of industrial applications. As industries continue to evolve and demand for high-quality metal products increases, the market is expected to play a vital role in supporting the growth and development of various sectors.

Global Single Stand Reversing Cold Mill Market Outlook:

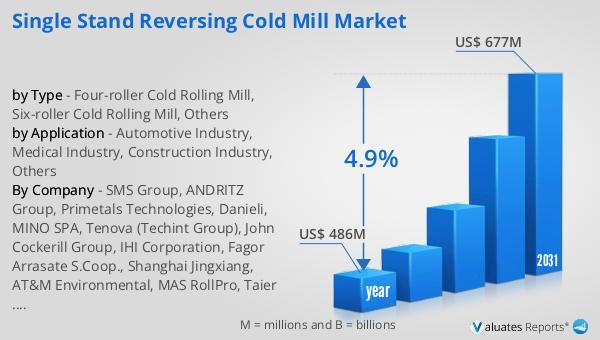

The global market for Single Stand Reversing Cold Mill was valued at $486 million in 2024 and is anticipated to grow to a revised size of $677 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.9% during the forecast period. This growth trajectory underscores the increasing demand for advanced cold rolling mills across various industries. The market's expansion is driven by several factors, including the rising need for high-quality metal sheets with precise mechanical properties, advancements in manufacturing technologies, and the growing emphasis on energy efficiency and sustainability. As industries such as automotive, construction, and electronics continue to evolve, the demand for high-performance cold rolling mills is expected to rise, further propelling the market's growth. Manufacturers are investing in research and development to enhance the capabilities of their equipment, incorporating advanced technologies such as artificial intelligence and machine learning to optimize performance and reduce operational costs. Additionally, the market is witnessing a shift towards sustainable manufacturing practices, with manufacturers exploring ways to minimize the environmental impact of cold rolling processes. This includes optimizing energy consumption, reducing waste, and developing eco-friendly products. As a result, the Global Single Stand Reversing Cold Mill Market is poised for continued growth, driven by the increasing demand for high-quality metal products and the ongoing advancements in manufacturing technologies.

| Report Metric | Details |

| Report Name | Single Stand Reversing Cold Mill Market |

| Accounted market size in year | US$ 486 million |

| Forecasted market size in 2031 | US$ 677 million |

| CAGR | 4.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SMS Group, ANDRITZ Group, Primetals Technologies, Danieli, MINO SPA, Tenova (Techint Group), John Cockerill Group, IHI Corporation, Fagor Arrasate S.Coop., Shanghai Jingxiang, AT&M Environmental, MAS RollPro, Taier Group, Jiangyin Zongyu Automation Equipment, Antai Environmental Engineering Technology, Wuhan Beikai Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |