What is Global Dual-Arm Robot for Wafer Handling Market?

The Global Dual-Arm Robot for Wafer Handling Market is a specialized segment within the robotics industry that focuses on the development and deployment of dual-arm robots specifically designed for handling wafers. Wafers are thin slices of semiconductor material, such as silicon, used in the fabrication of integrated circuits and other microdevices. These robots are engineered to perform precise and delicate operations, ensuring that wafers are handled with the utmost care to prevent damage or contamination. The dual-arm configuration allows for greater flexibility and efficiency, as the robots can perform simultaneous tasks, such as picking up a wafer with one arm while positioning it with the other. This market is driven by the increasing demand for semiconductors across various industries, including electronics, automotive, and telecommunications. As technology advances, the need for more sophisticated and efficient wafer handling solutions grows, making dual-arm robots an essential component in semiconductor manufacturing facilities. These robots not only enhance productivity but also improve the quality and consistency of wafer handling processes, contributing to the overall efficiency of semiconductor production. The market is characterized by continuous innovation and development, with companies striving to create more advanced and reliable dual-arm robots to meet the evolving needs of the semiconductor industry.

Atmospheric Robot, Vacuum Robot in the Global Dual-Arm Robot for Wafer Handling Market:

In the realm of the Global Dual-Arm Robot for Wafer Handling Market, two primary types of robots are utilized: Atmospheric Robots and Vacuum Robots. Atmospheric Robots operate in environments where the pressure is similar to the Earth's atmosphere. These robots are typically used in processes where wafers are exposed to air, such as during the initial stages of wafer handling or in certain inspection processes. Atmospheric Robots are designed to handle wafers delicately, ensuring that they are not exposed to contaminants or physical damage. They are equipped with advanced sensors and control systems that allow for precise movements and positioning, which is crucial in maintaining the integrity of the wafers. On the other hand, Vacuum Robots are used in environments where wafers need to be handled in a vacuum or controlled atmosphere. These robots are essential in processes such as chemical vapor deposition or etching, where the presence of air could interfere with the process or damage the wafers. Vacuum Robots are designed to operate in low-pressure environments, and they are equipped with specialized grippers and arms that can handle wafers without causing any damage. The dual-arm configuration of these robots allows for simultaneous handling of multiple wafers, increasing efficiency and throughput in semiconductor manufacturing processes. Both Atmospheric and Vacuum Robots play a crucial role in the Global Dual-Arm Robot for Wafer Handling Market, providing the necessary precision and reliability required in the semiconductor industry. As the demand for semiconductors continues to grow, the need for advanced wafer handling solutions becomes more critical, driving innovation and development in this market segment. Companies are continually working to improve the capabilities of these robots, incorporating new technologies and features to enhance their performance and adaptability in various wafer handling applications. The integration of artificial intelligence and machine learning in these robots is also becoming more prevalent, allowing for more autonomous and intelligent operations. This not only improves the efficiency of wafer handling processes but also reduces the likelihood of errors and defects, ultimately contributing to the overall quality and yield of semiconductor production. The Global Dual-Arm Robot for Wafer Handling Market is poised for significant growth as the semiconductor industry continues to expand and evolve, with Atmospheric and Vacuum Robots playing a pivotal role in meeting the demands of modern wafer handling applications.

200mm Wafer, 300mm Wafer, Others in the Global Dual-Arm Robot for Wafer Handling Market:

The usage of Global Dual-Arm Robots for Wafer Handling Market is particularly significant in the handling of 200mm and 300mm wafers, as well as other wafer sizes. In the case of 200mm wafers, these robots are employed to manage the handling processes with precision and care. The 200mm wafers are commonly used in the production of various semiconductor devices, and the dual-arm robots ensure that these wafers are handled efficiently and without damage. The robots' ability to perform simultaneous tasks with their dual arms allows for increased throughput and productivity in the manufacturing process. Additionally, the advanced sensors and control systems integrated into these robots enable them to handle 200mm wafers with the utmost accuracy, reducing the risk of contamination or defects. When it comes to 300mm wafers, the demand for dual-arm robots is even more pronounced. The larger size of these wafers requires more sophisticated handling solutions to ensure their integrity throughout the manufacturing process. Dual-arm robots are particularly well-suited for this task, as their design allows for the simultaneous handling of multiple wafers, increasing efficiency and reducing cycle times. The precision and reliability of these robots are crucial in maintaining the quality of 300mm wafers, which are used in the production of advanced semiconductor devices. The robots' ability to operate in both atmospheric and vacuum environments further enhances their versatility and applicability in various wafer handling processes. In addition to 200mm and 300mm wafers, dual-arm robots are also used in the handling of other wafer sizes and types. This includes specialized wafers used in niche applications or emerging technologies. The adaptability of dual-arm robots makes them an ideal solution for handling a wide range of wafer sizes and types, ensuring that they can meet the diverse needs of the semiconductor industry. As the demand for semiconductors continues to grow, the need for efficient and reliable wafer handling solutions becomes increasingly important. The Global Dual-Arm Robot for Wafer Handling Market is well-positioned to address these needs, providing advanced robotic solutions that enhance productivity, quality, and consistency in semiconductor manufacturing processes. The continuous development and innovation in this market segment ensure that dual-arm robots remain at the forefront of wafer handling technology, meeting the evolving demands of the semiconductor industry and contributing to its ongoing growth and success.

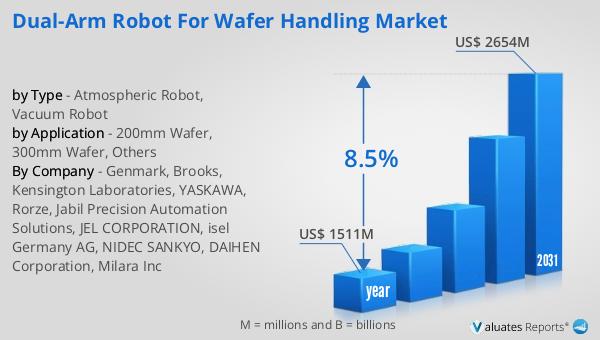

Global Dual-Arm Robot for Wafer Handling Market Outlook:

In 2024, the Global Dual-Arm Robot for Wafer Handling Market was valued at approximately $1,511 million. By 2031, it is anticipated to expand to a revised size of around $2,654 million, reflecting a compound annual growth rate (CAGR) of 8.5% over the forecast period. This growth trajectory underscores the increasing demand for dual-arm robots in the semiconductor industry, driven by the need for more efficient and precise wafer handling solutions. The market's expansion is fueled by advancements in technology and the growing complexity of semiconductor manufacturing processes, which require sophisticated robotic solutions to maintain productivity and quality. Notably, regions such as North America, Europe, and Japan collectively hold a significant portion of the market, accounting for 23% of the global share. This indicates a strong presence and demand for dual-arm robots in these regions, where the semiconductor industry is well-established and continues to evolve. The market outlook for dual-arm robots in wafer handling is promising, with continuous innovation and development expected to drive further growth and adoption across various industries. As the semiconductor industry continues to expand, the need for advanced robotic solutions becomes increasingly critical, positioning the Global Dual-Arm Robot for Wafer Handling Market as a key player in meeting the demands of modern semiconductor manufacturing.

| Report Metric | Details |

| Report Name | Dual-Arm Robot for Wafer Handling Market |

| Accounted market size in year | US$ 1511 million |

| Forecasted market size in 2031 | US$ 2654 million |

| CAGR | 8.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Genmark, Brooks, Kensington Laboratories, YASKAWA, Rorze, Jabil Precision Automation Solutions, JEL CORPORATION, isel Germany AG, NIDEC SANKYO, DAIHEN Corporation, Milara Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |