What is Global Gearbox for Wind Turbine Market?

The Global Gearbox for Wind Turbine Market is a crucial component of the wind energy sector, playing a vital role in the conversion of kinetic energy from wind into electrical energy. A gearbox in a wind turbine is responsible for increasing the rotational speed of the blades to a level that is suitable for electricity generation. This is achieved by connecting the low-speed shaft, which is turned by the turbine blades, to the high-speed shaft that drives the generator. The gearbox thus acts as a mediator, ensuring that the energy captured by the blades is efficiently transferred to the generator. The market for these gearboxes is driven by the increasing demand for renewable energy sources, as countries worldwide strive to reduce their carbon footprints and transition to sustainable energy solutions. As wind energy becomes more prevalent, the demand for efficient and reliable gearboxes continues to grow, making this market a significant player in the global push towards cleaner energy. The market is characterized by technological advancements aimed at improving the efficiency and durability of gearboxes, as well as efforts to reduce maintenance costs and enhance the overall performance of wind turbines.

Planetary Gears, Spur Gears, Bevel Gears, Helical Gears in the Global Gearbox for Wind Turbine Market:

Planetary gears, spur gears, bevel gears, and helical gears are integral components of the Global Gearbox for Wind Turbine Market, each serving distinct functions to optimize the performance of wind turbines. Planetary gears, also known as epicyclic gears, are renowned for their compact design and high power density, making them ideal for applications where space and weight are critical factors. These gears consist of a central sun gear, planet gears, and an outer ring gear, working together to distribute the load evenly and provide high torque transmission. This design is particularly beneficial in wind turbines, where the gearbox must handle varying loads and speeds efficiently. Spur gears, on the other hand, are characterized by their straight teeth and parallel shaft alignment. They are known for their simplicity and efficiency in transmitting power between parallel shafts. In wind turbines, spur gears are often used in conjunction with other gear types to achieve the desired speed and torque conversion. Bevel gears are distinguished by their conical shape, allowing them to transmit power between intersecting shafts at various angles. This capability is essential in wind turbines, where the gearbox must accommodate the changing orientation of the turbine blades as they capture wind from different directions. Helical gears, with their angled teeth, offer smoother and quieter operation compared to spur gears. The angled teeth engage gradually, reducing noise and vibration, which is crucial in maintaining the structural integrity of the wind turbine and minimizing wear and tear. Helical gears are often used in the main gearbox of wind turbines to ensure efficient power transmission and enhance the overall performance of the system. Each of these gear types plays a vital role in the functionality of wind turbine gearboxes, contributing to the efficient conversion of wind energy into electrical power. The choice of gear type depends on various factors, including the specific requirements of the wind turbine, the desired efficiency, and the operational conditions. As the demand for wind energy continues to rise, the development and optimization of these gear types remain a focal point for manufacturers and researchers in the Global Gearbox for Wind Turbine Market.

Onshore, Offshore in the Global Gearbox for Wind Turbine Market:

The usage of Global Gearbox for Wind Turbine Market in onshore and offshore applications highlights the versatility and adaptability of these systems in harnessing wind energy across different environments. Onshore wind turbines are typically installed on land, where they benefit from easier access for installation and maintenance. The gearboxes used in onshore wind turbines are designed to withstand varying weather conditions and terrain, ensuring reliable performance and longevity. Onshore wind farms are often located in areas with consistent wind patterns, allowing for efficient energy generation. The gearboxes in these turbines must be robust and capable of handling the mechanical stresses associated with fluctuating wind speeds and directions. Offshore wind turbines, on the other hand, are installed in bodies of water, such as oceans or large lakes, where wind speeds are generally higher and more consistent than on land. The gearboxes used in offshore wind turbines face unique challenges, including exposure to harsh marine environments, saltwater corrosion, and the logistical complexities of installation and maintenance. To address these challenges, offshore gearboxes are engineered with advanced materials and coatings to resist corrosion and enhance durability. Additionally, they are designed to accommodate the larger size and higher capacity of offshore turbines, which are often built to capture the stronger and more consistent winds found at sea. The increased energy output of offshore wind farms makes them an attractive option for countries looking to expand their renewable energy portfolios. Both onshore and offshore applications of wind turbine gearboxes contribute significantly to the global energy landscape, providing clean and sustainable power to meet the growing demand for electricity. The continued development and optimization of gearbox technology are essential to maximizing the efficiency and reliability of wind energy systems, ensuring that they remain a viable and competitive source of renewable energy. As the Global Gearbox for Wind Turbine Market evolves, the focus remains on enhancing the performance and durability of gearboxes to support the expansion of wind energy infrastructure worldwide.

Global Gearbox for Wind Turbine Market Outlook:

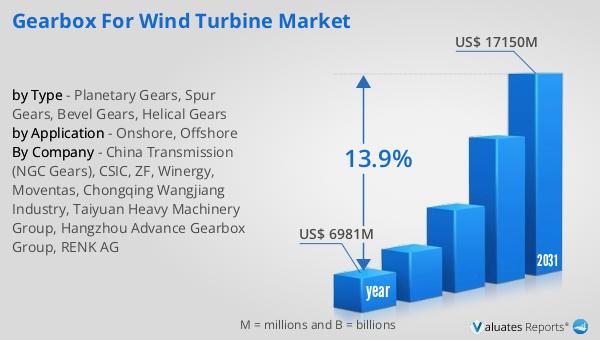

The global market for gearboxes used in wind turbines was valued at approximately $6,981 million in 2024. This market is anticipated to expand significantly, reaching an estimated value of $17,150 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 13.9% over the forecast period. This impressive growth rate underscores the increasing demand for wind energy solutions as part of the global shift towards renewable energy sources. The expansion of the gearbox market is driven by several factors, including technological advancements in gearbox design, the rising adoption of wind energy across various regions, and the need for efficient and reliable power transmission systems in wind turbines. As countries strive to reduce their carbon emissions and transition to cleaner energy sources, the demand for wind turbines and their components, such as gearboxes, is expected to rise. The market's growth is also supported by government initiatives and policies promoting renewable energy development, as well as investments in wind energy infrastructure. As the market continues to evolve, manufacturers and researchers are focused on enhancing the efficiency, durability, and cost-effectiveness of gearboxes to meet the growing demand and support the expansion of wind energy capacity worldwide.

| Report Metric | Details |

| Report Name | Gearbox for Wind Turbine Market |

| Accounted market size in year | US$ 6981 million |

| Forecasted market size in 2031 | US$ 17150 million |

| CAGR | 13.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | China Transmission (NGC Gears), CSIC, ZF, Winergy, Moventas, Chongqing Wangjiang Industry, Taiyuan Heavy Machinery Group, Hangzhou Advance Gearbox Group, RENK AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |