What is Global Automatic Tray Sealer for Food Market?

The Global Automatic Tray Sealer for Food Market is a dynamic segment within the packaging industry that focuses on sealing trays containing various food products. These machines are designed to enhance the shelf life of food by providing airtight seals, which help in preserving freshness and preventing contamination. The market is driven by the increasing demand for convenient and ready-to-eat food products, which require efficient packaging solutions. Automatic tray sealers are widely used in food processing industries to ensure that products are securely packaged, maintaining their quality during transportation and storage. The market encompasses a range of machines that vary in size, capacity, and automation level, catering to different production needs. With advancements in technology, these sealers have become more efficient, offering features like vacuum sealing and modified atmosphere packaging, which further extend the shelf life of food products. The global market is witnessing growth due to the rising awareness about food safety and the need for sustainable packaging solutions. As consumers continue to demand high-quality, fresh, and safe food products, the role of automatic tray sealers becomes increasingly significant in the food packaging industry.

Semi-automatic, Fully Automatic in the Global Automatic Tray Sealer for Food Market:

In the Global Automatic Tray Sealer for Food Market, machines are categorized based on their level of automation, primarily into semi-automatic and fully automatic tray sealers. Semi-automatic tray sealers require some level of human intervention during the sealing process. Operators are typically needed to load trays into the machine and initiate the sealing cycle. These machines are ideal for small to medium-sized food processing businesses where production volumes are not extremely high. They offer flexibility and are often more affordable than their fully automatic counterparts, making them a popular choice for businesses looking to balance cost with efficiency. Semi-automatic tray sealers are designed to handle a variety of tray sizes and materials, providing versatility in packaging different types of food products. On the other hand, fully automatic tray sealers are designed for high-volume production environments. These machines operate with minimal human intervention, as they are equipped with advanced features such as automatic tray loading, sealing, and unloading. Fully automatic tray sealers are capable of handling large quantities of trays in a continuous process, significantly increasing production efficiency. They are often integrated with other automated systems in a production line, such as filling and labeling machines, to create a seamless packaging process. The choice between semi-automatic and fully automatic tray sealers depends on several factors, including production volume, budget, and the specific needs of the food processing operation. Fully automatic machines are generally more expensive but offer higher throughput and reduced labor costs in the long run. They are suitable for large-scale manufacturers who require consistent and high-speed packaging solutions. In contrast, semi-automatic machines are more suited for smaller operations or those with variable production demands. Both types of machines contribute to the overall efficiency and effectiveness of the food packaging process, ensuring that food products are securely sealed and protected from external contaminants. As the demand for packaged food continues to rise, the market for both semi-automatic and fully automatic tray sealers is expected to grow, driven by the need for reliable and efficient packaging solutions.

Fresh Food, Ready Food, Processed Food in the Global Automatic Tray Sealer for Food Market:

The Global Automatic Tray Sealer for Food Market plays a crucial role in the packaging of various food categories, including fresh food, ready food, and processed food. In the fresh food segment, automatic tray sealers are essential for maintaining the freshness and quality of products such as fruits, vegetables, and meats. These machines provide airtight seals that prevent the entry of air and moisture, which can lead to spoilage. By extending the shelf life of fresh food products, tray sealers help reduce food waste and ensure that consumers receive high-quality products. In the ready food category, automatic tray sealers are used to package meals that are pre-cooked and require minimal preparation before consumption. These meals are often packaged in trays that are sealed to preserve their flavor and texture. The use of tray sealers in this segment is driven by the growing demand for convenient meal solutions, as more consumers seek quick and easy options for their busy lifestyles. Tray sealers ensure that ready meals are securely packaged, preventing leaks and spills during transportation and storage. In the processed food segment, automatic tray sealers are used to package a wide range of products, including snacks, baked goods, and dairy products. These machines provide a reliable sealing solution that protects processed foods from contamination and extends their shelf life. The use of tray sealers in this segment is particularly important for maintaining the quality and safety of products that are distributed over long distances. By providing a secure seal, tray sealers help ensure that processed foods remain fresh and safe for consumption. Overall, the Global Automatic Tray Sealer for Food Market is integral to the packaging of fresh, ready, and processed foods, providing solutions that enhance product quality, safety, and shelf life.

Global Automatic Tray Sealer for Food Market Outlook:

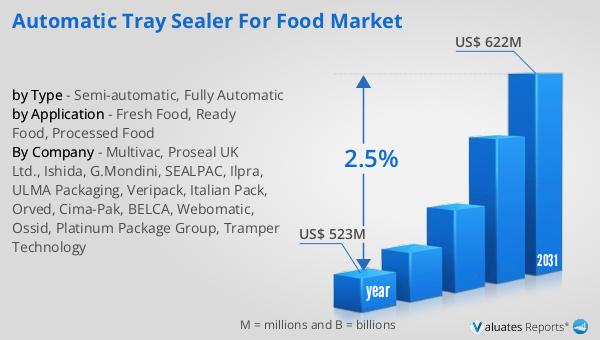

The global market for Automatic Tray Sealer for Food was valued at $523 million in 2024, and it is anticipated to grow to a revised size of $622 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.5% over the forecast period. This growth trajectory indicates a steady increase in demand for automatic tray sealers, driven by the rising need for efficient and reliable food packaging solutions. The market's expansion is fueled by several factors, including the growing consumer preference for packaged and ready-to-eat foods, which require secure and effective packaging to maintain quality and safety. Additionally, advancements in sealing technology and the increasing focus on sustainable packaging solutions are contributing to the market's growth. As the food industry continues to evolve, the demand for automatic tray sealers is expected to rise, as these machines offer a practical solution for extending the shelf life of food products and reducing food waste. The projected growth in the market underscores the importance of automatic tray sealers in the food packaging industry, as they play a critical role in ensuring that food products are safely and efficiently packaged for distribution and consumption.

| Report Metric | Details |

| Report Name | Automatic Tray Sealer for Food Market |

| Accounted market size in year | US$ 523 million |

| Forecasted market size in 2031 | US$ 622 million |

| CAGR | 2.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Multivac, Proseal UK Ltd., Ishida, G.Mondini, SEALPAC, Ilpra, ULMA Packaging, Veripack, Italian Pack, Orved, Cima-Pak, BELCA, Webomatic, Ossid, Platinum Package Group, Tramper Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |