What is Global Industrial Shredding Machine Market?

The Global Industrial Shredding Machine Market is a dynamic and essential segment within the broader machinery industry, focusing on the design, production, and distribution of shredding machines used across various sectors. These machines are pivotal in reducing the size of materials, making them easier to handle, recycle, or dispose of. Industrial shredders are employed in numerous applications, including waste management, recycling, and manufacturing processes, where they help in breaking down materials such as metals, plastics, wood, and paper. The market is driven by the increasing need for efficient waste management solutions and the growing emphasis on recycling and sustainability. As industries strive to minimize their environmental footprint, the demand for shredding machines that can handle diverse materials efficiently is on the rise. Technological advancements have also played a significant role in shaping the market, with modern shredders offering enhanced capabilities, such as energy efficiency, automation, and improved safety features. The market is characterized by a wide range of products, catering to different industrial needs, from small-scale operations to large manufacturing plants. Overall, the Global Industrial Shredding Machine Market is poised for growth as industries continue to prioritize sustainability and efficient resource management.

Single Shaft, Two Shaft, Four Shaft, Others in the Global Industrial Shredding Machine Market:

In the Global Industrial Shredding Machine Market, machines are categorized based on their shaft configurations, which significantly influence their functionality and application. Single Shaft shredders are designed with one shaft and are ideal for processing materials that require a consistent particle size. These machines are commonly used for shredding plastics, wood, and paper, where precision and uniformity are crucial. They are equipped with a rotor and stationary knives, which work together to cut materials into smaller pieces. Single Shaft shredders are known for their simplicity, ease of maintenance, and ability to handle a wide range of materials, making them a popular choice for many industries. Two Shaft shredders, on the other hand, feature two parallel shafts that rotate in opposite directions. This configuration allows them to handle larger and more challenging materials, such as metals and bulky waste. The interlocking blades on the shafts pull materials in and shear them, making Two Shaft shredders ideal for applications where volume reduction is a priority. They are robust and versatile, capable of processing a variety of materials, including tires, electronic waste, and industrial scrap. Four Shaft shredders take the concept further by incorporating four shafts, providing even greater shredding capabilities. These machines are designed for complex and demanding applications, where precise size reduction and high throughput are required. The additional shafts allow for finer shredding and better control over the output size, making them suitable for recycling operations that deal with mixed materials. Four Shaft shredders are often used in industries that require the processing of hazardous waste, confidential documents, and other sensitive materials. Lastly, the "Others" category in the Global Industrial Shredding Machine Market includes specialized shredders that do not fit into the standard shaft configurations. These machines are designed for niche applications and may incorporate unique features to address specific industrial needs. For example, some shredders are equipped with advanced sorting and separation technologies, enabling them to process complex waste streams more efficiently. Others may be designed for mobile operations, allowing them to be deployed in remote locations or used for on-site shredding. Overall, the diversity in shaft configurations within the Global Industrial Shredding Machine Market reflects the wide range of applications and industries that rely on these machines for efficient material processing and waste management.

MSW Recycling, WEEE Recycling, Paper Recycling, Wood Recycling, Scrap Metal Recycling, Others in the Global Industrial Shredding Machine Market:

The Global Industrial Shredding Machine Market plays a crucial role in various recycling and waste management applications, contributing significantly to environmental sustainability and resource conservation. In the realm of Municipal Solid Waste (MSW) Recycling, industrial shredders are indispensable. They help in reducing the volume of waste, making it easier to handle and process. By breaking down large and bulky items, shredders facilitate the separation and sorting of recyclable materials, such as plastics, metals, and paper, from non-recyclable waste. This process not only aids in efficient waste management but also enhances the recovery of valuable resources, reducing the burden on landfills. In Waste Electrical and Electronic Equipment (WEEE) Recycling, shredders are vital for dismantling and processing electronic waste. These machines can handle a wide range of electronic devices, from small gadgets to large appliances, breaking them down into smaller components. This size reduction is essential for the subsequent separation and recovery of valuable materials, such as precious metals and rare earth elements, which are often found in electronic waste. Shredders also play a significant role in Paper Recycling, where they are used to process waste paper into smaller pieces, making it easier to pulp and recycle. By efficiently shredding paper, these machines help in reducing the energy and resources required for recycling, contributing to a more sustainable paper production process. In Wood Recycling, industrial shredders are used to process waste wood, such as pallets, construction debris, and tree branches, into smaller chips or sawdust. This material can then be used for various applications, including the production of particleboard, mulch, and bioenergy. Shredders help in maximizing the value of waste wood, turning it into a valuable resource rather than letting it go to waste. Scrap Metal Recycling is another area where industrial shredders are indispensable. These machines can process a wide range of metal waste, from small aluminum cans to large steel beams, reducing them to manageable sizes for further processing. By efficiently shredding scrap metal, these machines facilitate the recovery and recycling of valuable metals, reducing the need for virgin materials and conserving natural resources. Lastly, the "Others" category in the Global Industrial Shredding Machine Market includes specialized applications, such as the shredding of textiles, rubber, and other niche materials. These machines are designed to handle specific waste streams, providing tailored solutions for industries with unique recycling and waste management needs. Overall, the Global Industrial Shredding Machine Market is integral to various recycling and waste management processes, supporting industries in their efforts to minimize environmental impact and promote sustainable resource use.

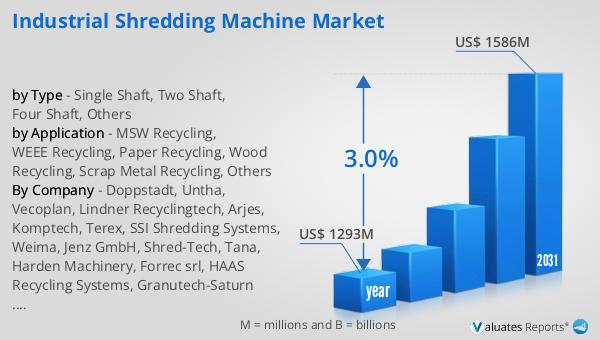

Global Industrial Shredding Machine Market Outlook:

The worldwide market for Industrial Shredding Machines was valued at approximately $1,293 million in 2024. It is anticipated to grow to a revised size of about $1,586 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.0% over the forecast period. This growth trajectory underscores the increasing demand for efficient and versatile shredding solutions across various industries. As businesses and governments worldwide place a greater emphasis on sustainability and waste reduction, the need for advanced shredding technology becomes more pronounced. Industrial shredders are crucial in facilitating recycling processes, reducing waste volume, and recovering valuable materials, which are key factors driving market expansion. The projected growth also highlights the ongoing technological advancements in shredding machinery, which are enhancing their efficiency, safety, and adaptability to different materials and applications. As industries continue to evolve and adapt to environmental regulations and consumer expectations, the role of shredding machines in achieving these goals becomes increasingly significant. The market's steady growth reflects a broader trend towards sustainable industrial practices and the adoption of innovative technologies that support these efforts. Overall, the Global Industrial Shredding Machine Market is poised for continued expansion as it aligns with global sustainability initiatives and the growing need for efficient waste management solutions.

| Report Metric | Details |

| Report Name | Industrial Shredding Machine Market |

| Accounted market size in year | US$ 1293 million |

| Forecasted market size in 2031 | US$ 1586 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Doppstadt, Untha, Vecoplan, Lindner Recyclingtech, Arjes, Komptech, Terex, SSI Shredding Systems, Weima, Jenz GmbH, Shred-Tech, Tana, Harden Machinery, Forrec srl, HAAS Recycling Systems, Granutech-Saturn Systems, ZERMA, Allegheny, Genox, Cresswood, Erdwich, William |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |