What is Global Pharmaceutical X-ray Inspection System Market?

The Global Pharmaceutical X-ray Inspection System Market is a specialized segment within the broader medical imaging industry, focusing on the use of X-ray technology to ensure the quality and safety of pharmaceutical products. These systems are designed to detect foreign particles, verify the integrity of packaging, and ensure the correct dosage of medications. As the pharmaceutical industry continues to grow, driven by increasing demand for medications and stringent regulatory requirements, the need for advanced inspection systems has become more critical. X-ray inspection systems offer a non-destructive method to examine products, providing a high level of accuracy and reliability. They are capable of detecting contaminants such as glass, metal, and stone, which are invisible to the naked eye. Additionally, these systems help in maintaining compliance with international safety standards, thereby reducing the risk of product recalls and enhancing consumer trust. The market for these systems is expanding globally, with significant investments in research and development to improve their efficiency and effectiveness. As a result, the Global Pharmaceutical X-ray Inspection System Market is poised for substantial growth, driven by technological advancements and the increasing complexity of pharmaceutical products.

Digital Radiography (DR) Type, Computed Tomography (CT) Type in the Global Pharmaceutical X-ray Inspection System Market:

Digital Radiography (DR) and Computed Tomography (CT) are two prominent types of X-ray inspection technologies used in the Global Pharmaceutical X-ray Inspection System Market. Digital Radiography (DR) is a form of X-ray imaging where digital sensors are used instead of traditional photographic film. This technology offers several advantages, including immediate image preview and availability, elimination of costly film processing steps, and the ability to digitally transfer and enhance images. In the pharmaceutical industry, DR is used to inspect the integrity of packaging, such as blister packs and bottles, ensuring that they are sealed correctly and free from contaminants. The high-resolution images produced by DR systems allow for precise detection of foreign particles, ensuring the safety and efficacy of pharmaceutical products. Moreover, DR systems are known for their speed and efficiency, making them ideal for high-throughput environments where large volumes of products need to be inspected quickly. On the other hand, Computed Tomography (CT) provides a more detailed and comprehensive analysis by creating three-dimensional images of the object being inspected. CT technology is particularly useful in the pharmaceutical industry for analyzing complex products, such as multi-layer tablets and intricate packaging designs. By providing a cross-sectional view of the product, CT systems can detect internal defects and inconsistencies that may not be visible with traditional X-ray methods. This level of detail is crucial for ensuring the quality and safety of pharmaceutical products, especially as they become more complex and customized. CT systems are also used in research and development to analyze the structural integrity of new drug formulations and packaging designs, helping manufacturers optimize their products before they reach the market. Both DR and CT technologies play a vital role in the Global Pharmaceutical X-ray Inspection System Market, each offering unique benefits that cater to different inspection needs. While DR is favored for its speed and efficiency in high-volume production environments, CT is preferred for its detailed analysis capabilities, making it ideal for research and development applications. As the pharmaceutical industry continues to evolve, the demand for advanced X-ray inspection technologies is expected to grow, driven by the need for higher quality standards and the increasing complexity of pharmaceutical products. Manufacturers are investing in the development of more sophisticated DR and CT systems, incorporating features such as artificial intelligence and machine learning to enhance their capabilities. These advancements are expected to further drive the growth of the Global Pharmaceutical X-ray Inspection System Market, providing manufacturers with the tools they need to ensure the safety and efficacy of their products.

Pharmaceutical, Bio-pharmaceutical in the Global Pharmaceutical X-ray Inspection System Market:

The Global Pharmaceutical X-ray Inspection System Market plays a crucial role in ensuring the quality and safety of pharmaceutical and bio-pharmaceutical products. In the pharmaceutical sector, X-ray inspection systems are used to detect foreign particles and contaminants in medications, ensuring that they meet stringent safety standards. These systems are capable of identifying a wide range of contaminants, including metal, glass, and stone, which can compromise the safety and efficacy of pharmaceutical products. By providing a non-destructive method of inspection, X-ray systems allow manufacturers to maintain the integrity of their products while ensuring compliance with international safety standards. This is particularly important in the pharmaceutical industry, where even the smallest defect can have serious consequences for patient safety. In the bio-pharmaceutical sector, X-ray inspection systems are used to ensure the quality and safety of biologically derived products, such as vaccines and monoclonal antibodies. These products are often more complex than traditional pharmaceuticals, requiring advanced inspection technologies to ensure their safety and efficacy. X-ray systems are used to inspect the integrity of packaging, such as vials and syringes, ensuring that they are sealed correctly and free from contaminants. Additionally, X-ray systems are used to verify the correct dosage of bio-pharmaceutical products, ensuring that they meet the required specifications. This is particularly important in the bio-pharmaceutical industry, where precise dosing is critical to the safety and efficacy of the product. The use of X-ray inspection systems in the pharmaceutical and bio-pharmaceutical industries is driven by the need for higher quality standards and the increasing complexity of products. As these industries continue to evolve, the demand for advanced inspection technologies is expected to grow, driven by the need for higher quality standards and the increasing complexity of pharmaceutical products. Manufacturers are investing in the development of more sophisticated X-ray systems, incorporating features such as artificial intelligence and machine learning to enhance their capabilities. These advancements are expected to further drive the growth of the Global Pharmaceutical X-ray Inspection System Market, providing manufacturers with the tools they need to ensure the safety and efficacy of their products.

Global Pharmaceutical X-ray Inspection System Market Outlook:

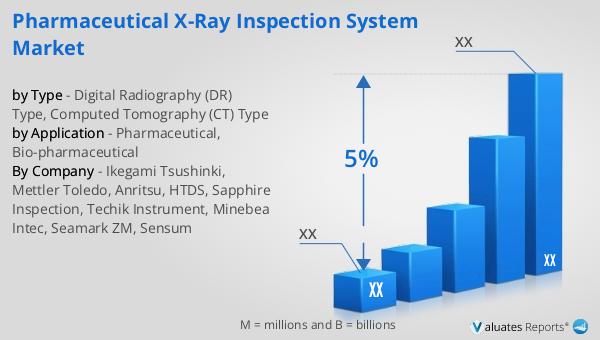

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, reflecting a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in drug development. In comparison, the chemical drug market has also shown significant growth, expanding from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth in the chemical drug market underscores the continued importance of traditional pharmaceuticals, even as the industry shifts towards more complex and biologically derived products. The expansion of both the global pharmaceutical market and the chemical drug market highlights the increasing need for advanced inspection technologies, such as X-ray inspection systems, to ensure the quality and safety of pharmaceutical products. As the industry continues to grow, manufacturers are investing in the development of more sophisticated inspection systems to meet the evolving needs of the market. These investments are expected to drive further growth in the Global Pharmaceutical X-ray Inspection System Market, providing manufacturers with the tools they need to ensure the safety and efficacy of their products.

| Report Metric | Details |

| Report Name | Pharmaceutical X-ray Inspection System Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ikegami Tsushinki, Mettler Toledo, Anritsu, HTDS, Sapphire Inspection, Techik Instrument, Minebea Intec, Seamark ZM, Sensum |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |