What is Global Inspection System for Food and Pharmaceutical Market?

The Global Inspection System for Food and Pharmaceutical Market is a comprehensive framework designed to ensure the safety, quality, and compliance of products within the food and pharmaceutical industries. This system encompasses a range of technologies and processes aimed at detecting and eliminating contaminants, ensuring that products meet stringent regulatory standards. In the food industry, inspection systems are crucial for identifying foreign objects, such as metal fragments or glass, that could pose a risk to consumers. Similarly, in the pharmaceutical sector, these systems are vital for verifying the integrity and purity of drugs, ensuring that they are free from contaminants and meet the required specifications. The global inspection system employs advanced technologies like metal detectors, X-ray inspection equipment, and vision systems to conduct thorough examinations of products at various stages of production. By implementing these systems, manufacturers can maintain high standards of quality control, reduce the risk of product recalls, and enhance consumer trust. Overall, the Global Inspection System for Food and Pharmaceutical Market plays a critical role in safeguarding public health and ensuring the integrity of products in these essential industries.

Metal Detectors, X-ray Inspection Equipment in the Global Inspection System for Food and Pharmaceutical Market:

Metal detectors and X-ray inspection equipment are integral components of the Global Inspection System for Food and Pharmaceutical Market, each serving distinct yet complementary roles in ensuring product safety and quality. Metal detectors are primarily used to identify and eliminate metal contaminants in food and pharmaceutical products. These devices work by generating a magnetic field and detecting disruptions caused by metal objects passing through it. When a metal contaminant is detected, the system triggers an alert, allowing for the removal of the affected product from the production line. This technology is particularly effective for detecting ferrous, non-ferrous, and stainless steel metals, making it a versatile tool for manufacturers. On the other hand, X-ray inspection equipment offers a more comprehensive solution by detecting a wider range of contaminants, including metal, glass, stone, bone, and dense plastic. X-ray systems work by passing X-rays through the product and capturing the resulting image, which is then analyzed for anomalies. This technology is highly effective for inspecting products with complex shapes or packaging, as it can penetrate through various materials to identify hidden contaminants. In the food industry, X-ray inspection equipment is used to ensure that products are free from foreign objects that could harm consumers. It is particularly useful for inspecting packaged goods, as it can detect contaminants without damaging the packaging. In the pharmaceutical sector, X-ray systems are employed to verify the integrity of tablets, capsules, and other dosage forms, ensuring that they are free from defects and meet quality standards. Both metal detectors and X-ray inspection equipment are essential for maintaining compliance with regulatory requirements, as they help manufacturers adhere to safety standards set by organizations such as the FDA and ISO. By integrating these technologies into their production processes, companies can reduce the risk of product recalls, protect their brand reputation, and enhance consumer confidence. Furthermore, advancements in technology have led to the development of more sophisticated inspection systems that offer improved sensitivity, accuracy, and ease of use. For instance, modern metal detectors are equipped with advanced algorithms that can differentiate between metal contaminants and product effects, reducing the likelihood of false positives. Similarly, X-ray inspection systems now feature high-resolution imaging and automated analysis capabilities, allowing for faster and more accurate detection of contaminants. As the demand for safe and high-quality food and pharmaceutical products continues to grow, the role of metal detectors and X-ray inspection equipment in the Global Inspection System for Food and Pharmaceutical Market becomes increasingly important. These technologies not only help manufacturers comply with regulatory standards but also contribute to the overall safety and quality of products, ultimately benefiting consumers worldwide.

Food, Pharmaceutical in the Global Inspection System for Food and Pharmaceutical Market:

The Global Inspection System for Food and Pharmaceutical Market plays a crucial role in ensuring the safety and quality of products in both the food and pharmaceutical industries. In the food sector, inspection systems are used to detect and eliminate contaminants that could pose a risk to consumers. This includes foreign objects such as metal fragments, glass, and plastic, as well as biological contaminants like bacteria and viruses. By implementing advanced technologies such as metal detectors, X-ray inspection equipment, and vision systems, manufacturers can conduct thorough examinations of products at various stages of production. This helps to ensure that products meet stringent regulatory standards and are safe for consumption. In addition to detecting contaminants, inspection systems are also used to verify the quality and integrity of food products. For example, vision systems can be used to inspect the appearance of products, ensuring that they meet quality standards in terms of size, shape, and color. Similarly, X-ray inspection equipment can be used to verify the weight and fill level of packaged goods, ensuring that they meet labeling requirements. In the pharmaceutical industry, inspection systems are used to ensure the integrity and purity of drugs. This includes verifying that products are free from contaminants and meet the required specifications. For example, metal detectors can be used to detect metal fragments in tablets and capsules, while X-ray inspection equipment can be used to verify the integrity of blister packs and other packaging. In addition to detecting contaminants, inspection systems are also used to verify the quality and consistency of pharmaceutical products. For example, vision systems can be used to inspect the appearance of tablets and capsules, ensuring that they meet quality standards in terms of size, shape, and color. Similarly, X-ray inspection equipment can be used to verify the weight and fill level of liquid medications, ensuring that they meet labeling requirements. Overall, the Global Inspection System for Food and Pharmaceutical Market plays a critical role in safeguarding public health and ensuring the integrity of products in these essential industries. By implementing advanced inspection technologies, manufacturers can maintain high standards of quality control, reduce the risk of product recalls, and enhance consumer trust.

Global Inspection System for Food and Pharmaceutical Market Outlook:

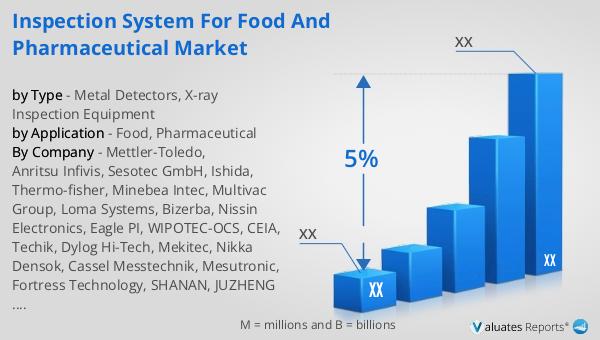

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, marking a significant milestone in the industry. This market is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years, reflecting the increasing demand for pharmaceutical products worldwide. This growth is driven by factors such as the rising prevalence of chronic diseases, advancements in drug development, and the expansion of healthcare infrastructure in emerging markets. In comparison, the chemical drug market has also experienced notable growth, with its value increasing from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth can be attributed to the continued demand for chemical drugs, which remain a cornerstone of modern medicine. The chemical drug market's expansion is supported by ongoing research and development efforts, as well as the introduction of new and innovative therapies. Both the pharmaceutical and chemical drug markets are expected to continue their upward trajectory, driven by the need for effective treatments and the growing emphasis on healthcare access and affordability. As these markets evolve, the role of inspection systems in ensuring product safety and quality becomes increasingly important, highlighting the critical need for robust quality control measures in the production and distribution of pharmaceutical products.

| Report Metric | Details |

| Report Name | Inspection System for Food and Pharmaceutical Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mettler-Toledo, Anritsu Infivis, Sesotec GmbH, Ishida, Thermo-fisher, Minebea Intec, Multivac Group, Loma Systems, Bizerba, Nissin Electronics, Eagle PI, WIPOTEC-OCS, CEIA, Techik, Dylog Hi-Tech, Mekitec, Nikka Densok, Cassel Messtechnik, Mesutronic, Fortress Technology, SHANAN, JUZHENG Electronic and Technology, Easyweigh |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |