What is Global Robot for Warehouse Market?

The Global Robot for Warehouse Market is a rapidly evolving sector that focuses on the integration of robotic technologies to enhance efficiency and productivity in warehouse operations. These robots are designed to automate various tasks such as sorting, picking, packing, and transporting goods within a warehouse setting. The market is driven by the increasing demand for automation in logistics and supply chain management, as businesses strive to reduce operational costs and improve accuracy. With advancements in artificial intelligence and machine learning, these robots are becoming more sophisticated, capable of performing complex tasks with minimal human intervention. The adoption of warehouse robots is particularly prevalent in industries such as e-commerce, retail, and manufacturing, where the need for quick and efficient order fulfillment is paramount. As companies continue to expand their global reach, the demand for warehouse robots is expected to grow, offering significant opportunities for innovation and development in this field. The market is characterized by a diverse range of robotic solutions, each tailored to meet specific operational needs, thereby providing businesses with the flexibility to optimize their warehouse processes.

Robotic Arms, Collaborative Bots (Co-Bots), Mobile Rack Goods-To-Person (GTP) AMR, Roaming Shuttle AMRs, Unit Load Transport Autonomous Mobile Robots (AMR), Bot Sorter AMRs, Others in the Global Robot for Warehouse Market:

Robotic Arms are a fundamental component of the Global Robot for Warehouse Market, designed to perform tasks that require precision and strength, such as picking and placing items. These arms are equipped with sensors and cameras to identify and handle various products, making them indispensable in environments where accuracy is crucial. Collaborative Bots, or Co-Bots, are designed to work alongside human workers, enhancing productivity by taking over repetitive tasks while ensuring safety through advanced sensor technology. These bots are particularly useful in environments where human-robot interaction is necessary. Mobile Rack Goods-To-Person (GTP) AMRs are autonomous mobile robots that transport racks of goods to human pickers, streamlining the picking process and reducing the time spent walking through aisles. This system is highly efficient in large warehouses with extensive inventories. Roaming Shuttle AMRs are designed to navigate warehouse floors independently, transporting goods between different locations. They are equipped with advanced navigation systems that allow them to avoid obstacles and optimize their routes, making them ideal for dynamic warehouse environments. Unit Load Transport Autonomous Mobile Robots (AMR) are specialized in moving large pallets or containers, offering a solution for heavy-duty transport tasks within warehouses. These robots are crucial in industries where bulk movement of goods is common. Bot Sorter AMRs are used for sorting items based on predefined criteria, such as size, weight, or destination. They enhance the sorting process by reducing errors and increasing speed, which is vital in high-volume operations. Other robotic solutions in the warehouse market include drones for inventory management and automated guided vehicles (AGVs) for transporting goods. Each of these technologies plays a unique role in optimizing warehouse operations, contributing to the overall efficiency and effectiveness of supply chain management.

Automobile, IT, Metal and Processing, Plastics and Polymers, Food and Beverage, Others in the Global Robot for Warehouse Market:

The usage of robots in the Global Robot for Warehouse Market spans various industries, each benefiting from the unique capabilities of these technologies. In the automobile industry, robots are used to manage the storage and retrieval of heavy automotive parts, ensuring that assembly lines are supplied with the necessary components without delay. This automation reduces the risk of human error and enhances the overall efficiency of production processes. In the IT sector, warehouse robots are employed to handle delicate electronic components, ensuring that they are stored and transported with precision and care. This is crucial in maintaining the integrity of sensitive equipment and minimizing damage during handling. The metal and processing industry utilizes robots for handling heavy metal parts and raw materials, streamlining the supply chain and reducing the physical strain on human workers. In the plastics and polymers industry, robots are used to manage the storage and distribution of raw materials and finished products, optimizing the flow of goods and reducing lead times. The food and beverage industry benefits from robots in managing perishable goods, ensuring that products are stored and transported under optimal conditions to maintain freshness and quality. Other industries, such as pharmaceuticals and retail, also leverage warehouse robots to enhance their operations, demonstrating the versatility and adaptability of these technologies across different sectors.

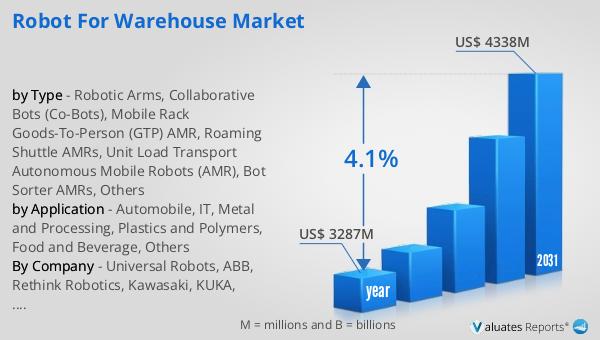

Global Robot for Warehouse Market Outlook:

The global market for robots in warehouses was valued at approximately $3,287 million in 2024, with projections indicating a growth to around $4,338 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.1% over the forecast period. Kuka, a leading manufacturer in this market, accounts for over 20% of the global market revenue, highlighting its significant influence and presence in the industry. North America holds the largest share of the global market, with its revenue exceeding 39%, underscoring the region's advanced adoption of warehouse automation technologies. The market's expansion is driven by the increasing demand for efficiency and accuracy in warehouse operations, as businesses seek to optimize their supply chains and reduce operational costs. The integration of advanced technologies such as artificial intelligence and machine learning is further propelling the market, enabling robots to perform complex tasks with greater precision and autonomy. As companies continue to invest in automation, the Global Robot for Warehouse Market is poised for significant growth, offering opportunities for innovation and development in the field of warehouse robotics.

| Report Metric | Details |

| Report Name | Robot for Warehouse Market |

| Accounted market size in year | US$ 3287 million |

| Forecasted market size in 2031 | US$ 4338 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Universal Robots, ABB, Rethink Robotics, Kawasaki, KUKA, FANUC, Ross, AR+, MR Motion Control, Camerobot, PhotoRobot, Electric Friends, Dongxu Robotics, Hanson Creative |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |