What is PTFE Thread Sealant Tapes - Global Market?

Polytetrafluoroethylene (PTFE) Thread Sealant Tapes are a crucial component in various industries, known for their exceptional sealing capabilities. These tapes are primarily used to ensure leak-free connections in threaded pipe systems. PTFE, a synthetic fluoropolymer, is renowned for its non-reactive and high-temperature resistant properties, making it ideal for sealing applications. The global market for PTFE Thread Sealant Tapes is vast, driven by the demand for reliable and durable sealing solutions in plumbing, pipefitting, and other related applications. These tapes are easy to use, requiring no curing time, and provide a clean, professional finish. They are available in various thicknesses and densities to suit different applications, from residential plumbing to industrial piping systems. The versatility and effectiveness of PTFE Thread Sealant Tapes make them a preferred choice for professionals and DIY enthusiasts alike, contributing to their widespread adoption across the globe. As industries continue to seek efficient and cost-effective sealing solutions, the demand for PTFE Thread Sealant Tapes is expected to grow, reflecting their importance in maintaining the integrity and safety of fluid and gas systems.

White Thread Sealant Tapes, Yellow Thread Sealant Tapes, Red Thread Sealant Tapes, Green Thread Sealant Tapes, Copper Thread Sealant Tapes, Silver Thread Sealant Tapes in the PTFE Thread Sealant Tapes - Global Market:

PTFE Thread Sealant Tapes come in various colors, each serving a specific purpose and application. White Thread Sealant Tapes are the most common and are typically used for general-purpose sealing in residential and commercial plumbing. They are suitable for water and air lines and are often used in applications where a standard seal is sufficient. Yellow Thread Sealant Tapes are specifically designed for gas lines, including natural gas and propane. Their thicker and denser composition provides a more robust seal, essential for preventing leaks in gas systems. Red Thread Sealant Tapes are used in high-pressure systems, often found in industrial applications. They offer superior strength and durability, making them ideal for sealing connections in environments where high pressure is a concern. Green Thread Sealant Tapes are used in oxygen lines, where contamination must be avoided. These tapes are oil-free and safe for use in oxygen-rich environments. Copper Thread Sealant Tapes are used in applications requiring high thermal conductivity, such as in heating systems. They provide a reliable seal while allowing for efficient heat transfer. Silver Thread Sealant Tapes are used in applications where electrical conductivity is required. They are often used in electronic and electrical systems to ensure a secure and conductive seal. Each color-coded tape is designed to meet specific industry standards and requirements, ensuring that the right tape is used for the right application. This color-coding system simplifies the selection process for professionals, ensuring that they can quickly and easily identify the appropriate tape for their needs. The global market for PTFE Thread Sealant Tapes is diverse, with each color serving a unique purpose and catering to different industries and applications. As industries continue to evolve and demand more specialized sealing solutions, the variety and specificity of PTFE Thread Sealant Tapes are expected to expand, providing even more options for professionals and consumers alike.

Building & Construction, Automotive and Transport, Oil & Gas, Petroleum, Chemical Processing, Pulp & Paper, Aerospace & Defense, Others in the PTFE Thread Sealant Tapes - Global Market:

PTFE Thread Sealant Tapes are widely used across various industries due to their versatility and effectiveness in creating leak-free seals. In the Building & Construction industry, these tapes are essential for plumbing applications, ensuring that water and air lines are securely sealed to prevent leaks and maintain system integrity. They are also used in HVAC systems to seal ductwork and prevent air leaks, contributing to energy efficiency and system performance. In the Automotive and Transport industry, PTFE Thread Sealant Tapes are used to seal fluid and air lines, ensuring that systems such as brakes, fuel lines, and air conditioning units operate safely and efficiently. The Oil & Gas industry relies heavily on these tapes to seal threaded connections in pipelines and equipment, preventing leaks and ensuring the safe transport of oil and gas. In the Petroleum industry, PTFE Thread Sealant Tapes are used to seal connections in refineries and processing plants, where high temperatures and pressures are common. The Chemical Processing industry uses these tapes to seal connections in chemical plants, where the non-reactive properties of PTFE are essential for preventing contamination and ensuring safety. In the Pulp & Paper industry, PTFE Thread Sealant Tapes are used to seal connections in processing equipment, where high temperatures and pressures are common. The Aerospace & Defense industry uses these tapes to seal connections in aircraft and defense systems, where reliability and safety are paramount. Other industries, such as food and beverage, pharmaceuticals, and electronics, also use PTFE Thread Sealant Tapes to ensure leak-free connections in their systems. The global market for PTFE Thread Sealant Tapes is vast and diverse, with applications spanning multiple industries and sectors. As industries continue to seek reliable and efficient sealing solutions, the demand for PTFE Thread Sealant Tapes is expected to grow, reflecting their importance in maintaining the integrity and safety of fluid and gas systems.

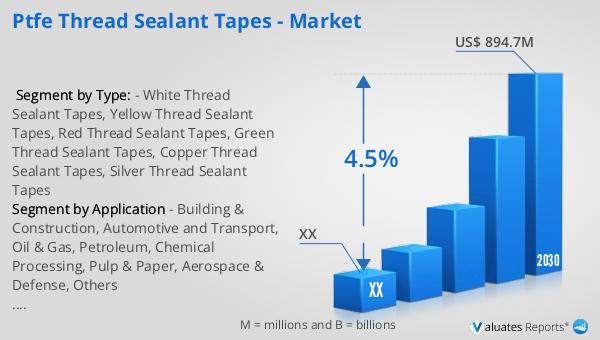

PTFE Thread Sealant Tapes - Global Market Outlook:

The global market for PTFE Thread Sealant Tapes was valued at approximately $665 million in 2023, with projections indicating a growth to around $894.7 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030. PTFE Thread Sealant Tapes, commonly known as thread sealing tapes or PTFE tapes, are extensively utilized in plumbing, pipefitting, and related applications to ensure a secure and leak-free seal on threaded connections. These tapes are favored for their ease of use, requiring no curing time, and their ability to provide a clean, professional finish. The demand for PTFE Thread Sealant Tapes is driven by the need for reliable and durable sealing solutions across various industries, including construction, automotive, oil and gas, and chemical processing. As industries continue to evolve and demand more efficient and cost-effective sealing solutions, the market for PTFE Thread Sealant Tapes is expected to expand, reflecting their importance in maintaining the integrity and safety of fluid and gas systems. The versatility and effectiveness of PTFE Thread Sealant Tapes make them a preferred choice for professionals and DIY enthusiasts alike, contributing to their widespread adoption across the globe.

| Report Metric | Details |

| Report Name | PTFE Thread Sealant Tapes - Market |

| Forecasted market size in 2030 | US$ 894.7 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel, H.B. Fuller, 3M, CSW Industrials, ITW Permatex, Oatey, LA-CO Industries, Swagelok, Permabond, WEICON, Hernon Manufacturing, ND Industries, Mill-Rose, FedPro, JC Whitlam Manufacturing, Loxeal S.r.l., Huron Industries, Anti-Seize Technology (AST), IPS Corporation, TFCO Incorporated, Bondloc UK, ManuSpec, Litai, Zhejiang Keli |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |