What is Dental Porcelain Furnaces - Global Market?

Dental porcelain furnaces are specialized equipment used in the dental industry to create dental prosthetics, such as crowns, bridges, and veneers, from porcelain materials. These furnaces are crucial in the dental laboratory setting as they provide the necessary heat to process and harden dental ceramics, ensuring that the final products are durable and aesthetically pleasing. The global market for dental porcelain furnaces is driven by the increasing demand for dental restorations and the growing awareness of oral health. As more people seek dental treatments for both functional and cosmetic reasons, the need for high-quality dental prosthetics rises, thereby boosting the demand for dental porcelain furnaces. Technological advancements in these furnaces, such as improved temperature control and energy efficiency, further contribute to their growing adoption in dental laboratories worldwide. Additionally, the rise in dental tourism and the expansion of dental care services in emerging markets are expected to fuel the growth of the dental porcelain furnaces market. As dental professionals strive to provide better patient outcomes, the role of dental porcelain furnaces becomes increasingly significant in the global dental industry.

Muffle Furnaces, Vacuum Furnaces, Others in the Dental Porcelain Furnaces - Global Market:

Muffle furnaces, vacuum furnaces, and other types of furnaces play a pivotal role in the dental porcelain furnaces market, each offering unique features and benefits tailored to specific dental applications. Muffle furnaces are widely used in dental laboratories due to their ability to provide uniform heat distribution, which is essential for the consistent firing of dental ceramics. These furnaces are designed with a heating chamber that is insulated from the outer environment, allowing for precise temperature control and minimizing heat loss. This makes muffle furnaces ideal for sintering dental porcelain, ensuring that the material achieves the desired hardness and translucency. On the other hand, vacuum furnaces are employed in situations where the elimination of air and other gases is crucial during the firing process. By creating a vacuum environment, these furnaces prevent oxidation and contamination of the dental ceramics, resulting in a higher quality finish. Vacuum furnaces are particularly beneficial for firing high-strength ceramics and metal-ceramic restorations, where maintaining the integrity of the material is paramount. Other types of furnaces used in the dental industry include infrared furnaces and microwave furnaces, which offer rapid heating capabilities and energy efficiency. Infrared furnaces utilize infrared radiation to heat dental materials quickly and evenly, reducing the overall processing time. This is advantageous in high-volume dental laboratories where time efficiency is critical. Microwave furnaces, on the other hand, use microwave energy to heat dental ceramics, offering a more energy-efficient alternative to traditional heating methods. These furnaces are gaining popularity due to their ability to reduce energy consumption and operational costs while maintaining high-quality results. The choice of furnace type in dental laboratories often depends on the specific requirements of the dental prosthetics being produced, as well as the laboratory's budget and production capacity. As the dental industry continues to evolve, the demand for advanced furnace technologies that offer improved performance, energy efficiency, and cost-effectiveness is expected to grow. Manufacturers are investing in research and development to introduce innovative furnace designs that cater to the diverse needs of dental professionals. This includes the integration of digital controls and automation features that enhance the precision and ease of use of dental porcelain furnaces. Furthermore, the increasing focus on sustainability and environmental responsibility is driving the development of eco-friendly furnace technologies that minimize energy consumption and reduce carbon emissions. As a result, the global market for dental porcelain furnaces is witnessing a shift towards more sustainable and technologically advanced solutions that meet the evolving demands of the dental industry.

Dental Hospitals, Dental Clinics, Others in the Dental Porcelain Furnaces - Global Market:

Dental porcelain furnaces are extensively used in various dental settings, including dental hospitals, dental clinics, and other specialized dental facilities, to fabricate high-quality dental restorations. In dental hospitals, these furnaces are integral to the production of dental prosthetics for patients requiring complex dental treatments. Dental hospitals often have in-house laboratories equipped with advanced porcelain furnaces to ensure that they can provide timely and efficient dental care. The use of these furnaces allows dental hospitals to produce custom-made prosthetics that meet the specific needs of each patient, enhancing the overall quality of care. In dental clinics, porcelain furnaces are used to create a range of dental restorations, from simple crowns to intricate veneers. Dental clinics rely on these furnaces to deliver precise and aesthetically pleasing results, which are crucial for maintaining patient satisfaction and trust. The ability to produce high-quality dental prosthetics in-house enables dental clinics to offer comprehensive dental services, reducing the need for outsourcing and improving turnaround times. Other specialized dental facilities, such as dental laboratories, also utilize porcelain furnaces to meet the growing demand for dental restorations. These laboratories often serve multiple dental practices, providing them with the necessary prosthetics to complete various dental procedures. The use of advanced porcelain furnaces in these facilities ensures that they can produce large volumes of dental restorations without compromising on quality. As the demand for dental care continues to rise, the role of dental porcelain furnaces in these settings becomes increasingly important. The ability to produce durable and aesthetically pleasing dental prosthetics is essential for meeting the expectations of patients and dental professionals alike. Furthermore, the integration of digital technologies in dental porcelain furnaces is transforming the way dental restorations are produced, offering greater precision and efficiency. This is particularly beneficial in dental hospitals and clinics, where the need for accurate and timely dental care is paramount. As dental professionals strive to provide the best possible outcomes for their patients, the use of advanced porcelain furnaces is becoming a standard practice in the dental industry.

Dental Porcelain Furnaces - Global Market Outlook:

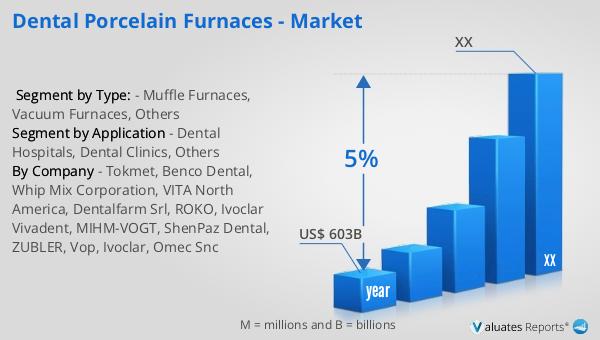

Based on our analysis, the global market for medical devices, which includes dental porcelain furnaces, is projected to reach approximately USD 603 billion in 2023. This market is anticipated to expand at a compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, the aging population, and the rising demand for advanced medical technologies. In the dental sector, the demand for dental porcelain furnaces is expected to grow as more people seek dental treatments for both functional and cosmetic purposes. The advancements in dental technology, such as digital dentistry and CAD/CAM systems, are also contributing to the growth of the dental porcelain furnaces market. These technologies enable dental professionals to produce high-quality dental restorations with greater precision and efficiency, driving the demand for advanced furnace solutions. Additionally, the expansion of dental care services in emerging markets and the rise in dental tourism are expected to further boost the demand for dental porcelain furnaces. As the global medical device market continues to grow, the dental porcelain furnaces segment is poised to benefit from the increasing focus on oral health and the demand for high-quality dental restorations.

| Report Metric | Details |

| Report Name | Dental Porcelain Furnaces - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Tokmet, Benco Dental, Whip Mix Corporation, VITA North America, Dentalfarm Srl, ROKO, Ivoclar Vivadent, MIHM-VOGT, ShenPaz Dental, ZUBLER, Vop, Ivoclar, Omec Snc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |