What is Smart Sonic Waterproof Electric Toothbrush - Global Market?

The Smart Sonic Waterproof Electric Toothbrush is a cutting-edge dental care device that has gained significant traction in the global market. This toothbrush is designed to provide an enhanced oral hygiene experience by utilizing advanced sonic technology, which delivers high-frequency vibrations to effectively clean teeth and gums. Its waterproof feature ensures durability and convenience, allowing users to safely use the toothbrush in wet environments, such as the shower. The global market for this innovative product is driven by increasing consumer awareness about oral health and the growing demand for technologically advanced personal care products. The toothbrush's ability to offer superior cleaning performance compared to traditional manual toothbrushes makes it a popular choice among consumers. Additionally, the sleek design and user-friendly features, such as multiple brushing modes and long battery life, contribute to its widespread appeal. As more people prioritize oral health and seek efficient dental care solutions, the Smart Sonic Waterproof Electric Toothbrush is poised to continue its growth trajectory in the global market.

Chargable, Battery in the Smart Sonic Waterproof Electric Toothbrush - Global Market:

The rechargeable, battery-based Smart Sonic Waterproof Electric Toothbrush represents a significant advancement in personal oral care technology. This toothbrush is equipped with a rechargeable battery, which offers the convenience of cordless operation and eliminates the need for constant battery replacements. The battery life of these toothbrushes is typically long-lasting, allowing users to enjoy extended periods of use before needing to recharge. This feature is particularly beneficial for travelers and individuals with busy lifestyles, as it reduces the frequency of charging and ensures the toothbrush is always ready for use. The charging process is often straightforward, with many models featuring a charging dock or USB charging capabilities, making it easy to power up the device using various power sources. The battery-based design also contributes to the toothbrush's portability, allowing users to maintain their oral hygiene routine wherever they go. In addition to convenience, the rechargeable battery supports the toothbrush's powerful sonic technology, which generates rapid vibrations to effectively remove plaque and debris from teeth and gums. This technology enhances the cleaning efficiency of the toothbrush, providing a thorough and gentle cleaning experience that is superior to manual brushing. The combination of sonic technology and a rechargeable battery makes this toothbrush an attractive option for consumers seeking a high-performance dental care solution. Furthermore, the waterproof feature of the toothbrush ensures that it can withstand exposure to water, making it suitable for use in the shower or during other water-related activities. This durability enhances the product's longevity and reliability, offering users peace of mind knowing that their investment is protected against water damage. The global market for rechargeable, battery-based Smart Sonic Waterproof Electric Toothbrushes is driven by several factors, including the increasing prevalence of oral health issues, rising consumer awareness about the benefits of advanced dental care products, and the growing demand for convenient and efficient personal care solutions. As more consumers recognize the importance of maintaining good oral hygiene, the demand for innovative toothbrushes that offer superior cleaning performance and user-friendly features is expected to rise. The rechargeable, battery-based Smart Sonic Waterproof Electric Toothbrush is well-positioned to meet this demand, offering a compelling combination of advanced technology, convenience, and durability. As a result, this product is likely to continue gaining popularity in the global market, appealing to a wide range of consumers seeking effective and reliable oral care solutions.

Aldult, Child in the Smart Sonic Waterproof Electric Toothbrush - Global Market:

The usage of the Smart Sonic Waterproof Electric Toothbrush varies across different age groups, particularly among adults and children, each benefiting from its advanced features in unique ways. For adults, this toothbrush offers a sophisticated solution to maintaining oral hygiene. Adults often face challenges such as plaque buildup, gum disease, and tooth sensitivity, which require effective cleaning methods. The Smart Sonic Waterproof Electric Toothbrush addresses these issues with its high-frequency sonic vibrations that efficiently remove plaque and debris, promoting healthier gums and teeth. The multiple brushing modes available in many models cater to specific needs, such as sensitive teeth or gum massage, allowing adults to customize their brushing experience. Additionally, the waterproof feature adds convenience, enabling adults to incorporate brushing into their shower routine, saving time and enhancing their daily hygiene regimen. For children, the Smart Sonic Waterproof Electric Toothbrush provides an engaging and effective way to develop good oral hygiene habits from a young age. The toothbrush's gentle yet powerful cleaning action ensures that children's teeth are thoroughly cleaned without causing discomfort. Many models designed for children come with fun and colorful designs, making brushing an enjoyable activity rather than a chore. Some toothbrushes also include interactive features, such as timers or music, to encourage children to brush for the recommended duration. The waterproof aspect is particularly beneficial for children, as it allows for easy cleaning and maintenance of the toothbrush, ensuring it remains hygienic and safe for use. Parents can feel confident that their children are receiving a high level of oral care with a toothbrush that is both effective and appealing to young users. Overall, the Smart Sonic Waterproof Electric Toothbrush serves as a versatile tool for both adults and children, offering tailored solutions to meet their specific oral care needs. Its advanced technology and user-friendly features make it an ideal choice for families seeking to improve their dental hygiene practices and promote long-term oral health.

Smart Sonic Waterproof Electric Toothbrush - Global Market Outlook:

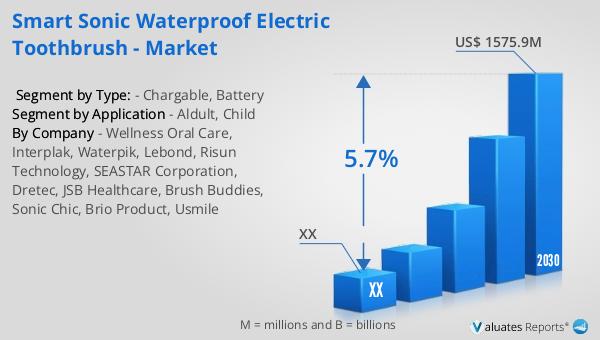

The global market outlook for the Smart Sonic Waterproof Electric Toothbrush indicates a promising growth trajectory. In 2023, the market was valued at approximately US$ 1073 million, reflecting the increasing consumer interest in advanced oral care solutions. This market is projected to expand significantly, reaching an estimated size of US$ 1575.9 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.7% during the forecast period from 2024 to 2030. This upward trend can be attributed to several factors, including the rising awareness of oral health, the demand for innovative and efficient dental care products, and the convenience offered by features such as waterproofing and rechargeable batteries. As consumers continue to prioritize their oral hygiene, the Smart Sonic Waterproof Electric Toothbrush is likely to maintain its appeal, driving further market expansion. The projected growth underscores the product's potential to capture a larger share of the global oral care market, appealing to a diverse range of consumers seeking effective and reliable dental care solutions. This positive market outlook highlights the toothbrush's role in shaping the future of oral hygiene practices worldwide, as more individuals recognize the benefits of incorporating advanced technology into their daily routines.

| Report Metric | Details |

| Report Name | Smart Sonic Waterproof Electric Toothbrush - Market |

| Forecasted market size in 2030 | US$ 1575.9 million |

| CAGR | 5.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Wellness Oral Care, Interplak, Waterpik, Lebond, Risun Technology, SEASTAR Corporation, Dretec, JSB Healthcare, Brush Buddies, Sonic Chic, Brio Product, Usmile |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |