What is Steel Belt Winding Machine - Global Market?

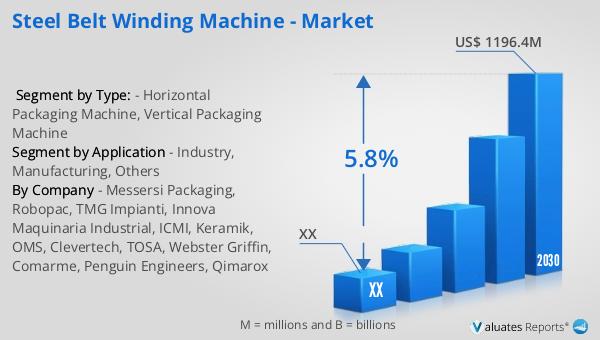

Steel Belt Winding Machines are specialized equipment designed to coil steel strips or similar materials into compact rolls. These machines play a crucial role in various industries by ensuring that steel strips are wound efficiently and uniformly, which is essential for storage, transportation, and further processing. The global market for these machines is significant, reflecting their importance in the industrial sector. In 2023, the market was valued at approximately US$ 806 million, and it is projected to grow to about US$ 1196.4 million by 2030, with a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is driven by the increasing demand for steel products across various industries, including construction, automotive, and manufacturing. The machines are designed to handle different types of steel strips, ensuring that they are wound with precision and consistency. This capability is vital for maintaining the quality and integrity of the steel during storage and transportation. As industries continue to expand and modernize, the demand for efficient and reliable steel belt winding machines is expected to rise, further fueling market growth.

Horizontal Packaging Machine, Vertical Packaging Machine in the Steel Belt Winding Machine - Global Market:

In the realm of packaging, both Horizontal and Vertical Packaging Machines have distinct roles, especially when integrated with Steel Belt Winding Machines. Horizontal Packaging Machines are primarily used for products that are packaged in a horizontal orientation. These machines are ideal for items that require a stable base during packaging, such as biscuits, chocolates, and other confectionery products. The integration of steel belt winding technology in these machines ensures that the packaging material is handled with precision and care, reducing the risk of damage or misalignment. The steel belt provides a robust and reliable mechanism for transporting packaging materials through the machine, ensuring that each package is sealed correctly and consistently. On the other hand, Vertical Packaging Machines are designed for products that are packaged in a vertical orientation. These machines are commonly used for packaging granular or powdered products, such as coffee, sugar, and spices. The use of steel belt winding technology in vertical packaging machines enhances their efficiency by ensuring that the packaging material is fed smoothly and accurately into the machine. This precision is crucial for maintaining the quality and consistency of the packaged product. The steel belt's durability and strength make it an ideal choice for handling the demands of high-speed packaging operations. Both horizontal and vertical packaging machines benefit from the integration of steel belt winding technology, as it enhances their performance and reliability. The global market for these machines is driven by the increasing demand for packaged goods across various industries. As consumer preferences shift towards convenience and ready-to-eat products, the need for efficient and reliable packaging solutions continues to grow. Steel belt winding machines play a vital role in meeting this demand by ensuring that packaging operations are carried out smoothly and efficiently. The versatility of these machines makes them suitable for a wide range of applications, from food and beverage to pharmaceuticals and cosmetics. As the global market for packaged goods continues to expand, the demand for advanced packaging machines, including those equipped with steel belt winding technology, is expected to rise. This growth is further supported by technological advancements in packaging machinery, which are aimed at improving efficiency, reducing waste, and enhancing the overall quality of packaged products. The integration of steel belt winding machines in packaging operations not only improves the performance of horizontal and vertical packaging machines but also contributes to the sustainability of packaging processes by minimizing material waste and energy consumption. As industries continue to prioritize sustainability and efficiency, the adoption of steel belt winding technology in packaging machines is likely to increase, driving further growth in the global market.

Industry, Manufacturing, Others in the Steel Belt Winding Machine - Global Market:

Steel Belt Winding Machines are utilized across various sectors, including industry, manufacturing, and other areas, due to their ability to efficiently coil steel strips into compact rolls. In the industrial sector, these machines are essential for the production and processing of steel products. They ensure that steel strips are wound with precision and consistency, which is crucial for maintaining the quality and integrity of the steel during storage and transportation. The use of steel belt winding machines in the industrial sector is driven by the increasing demand for steel products in construction, automotive, and other industries. In the manufacturing sector, steel belt winding machines are used to produce a wide range of products, from steel pipes and tubes to automotive components and machinery parts. These machines play a vital role in ensuring that steel strips are wound accurately and efficiently, which is essential for maintaining the quality and performance of the finished products. The use of steel belt winding machines in manufacturing is driven by the need for high-quality steel products that meet the stringent requirements of various industries. In addition to industry and manufacturing, steel belt winding machines are also used in other areas, such as packaging and logistics. In the packaging sector, these machines are used to wind steel strips into coils for use in packaging materials, such as steel bands and straps. The use of steel belt winding machines in packaging is driven by the need for durable and reliable packaging materials that can withstand the rigors of transportation and storage. In the logistics sector, steel belt winding machines are used to wind steel strips into coils for use in shipping and transportation. The use of steel belt winding machines in logistics is driven by the need for efficient and reliable transportation solutions that can handle the demands of global supply chains. Overall, the use of steel belt winding machines in various sectors is driven by the need for efficient and reliable solutions that can meet the demands of modern industries. As industries continue to expand and modernize, the demand for steel belt winding machines is expected to rise, further fueling market growth.

Steel Belt Winding Machine - Global Market Outlook:

The global market for Steel Belt Winding Machines was valued at approximately US$ 806 million in 2023. It is anticipated to grow to around US$ 1196.4 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. These machines are essential for winding steel strips or similar materials into coils, a process crucial for various industrial applications. The growth in this market is driven by the increasing demand for steel products across multiple sectors, including construction, automotive, and manufacturing. Steel Belt Winding Machines are designed to handle different types of steel strips, ensuring they are wound with precision and consistency. This capability is vital for maintaining the quality and integrity of the steel during storage and transportation. As industries continue to expand and modernize, the demand for efficient and reliable steel belt winding machines is expected to rise, further fueling market growth. The machines' ability to enhance productivity and reduce material waste makes them an attractive investment for companies looking to improve their operational efficiency. Additionally, technological advancements in these machines are expected to drive further growth in the market by offering improved performance and reliability.

| Report Metric | Details |

| Report Name | Steel Belt Winding Machine - Market |

| Forecasted market size in 2030 | US$ 1196.4 million |

| CAGR | 5.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Messersi Packaging, Robopac, TMG Impianti, Innova Maquinaria Industrial, ICMI, Keramik, OMS, Clevertech, TOSA, Webster Griffin, Comarme, Penguin Engineers, Qimarox |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |