What is Vertical Spiral Elevator Conveyor - Global Market?

The Vertical Spiral Elevator Conveyor is a specialized piece of equipment used in various industries to transport materials vertically. Unlike traditional conveyors that move items horizontally, this type of conveyor is designed to move products up or down in a spiral path, making it ideal for facilities with limited floor space. The global market for Vertical Spiral Elevator Conveyors is expanding due to the increasing demand for efficient material handling solutions in industries such as food processing, pharmaceuticals, and manufacturing. These conveyors are valued for their ability to handle a wide range of products, from small packages to bulk materials, with minimal spillage and high efficiency. They are also appreciated for their compact design, which allows them to fit into tight spaces while still providing a high throughput rate. As industries continue to seek ways to optimize their operations and reduce costs, the demand for Vertical Spiral Elevator Conveyors is expected to grow, driven by their versatility and efficiency in handling diverse materials.

Carbon Steel Material, Stainless Steel Material, Others in the Vertical Spiral Elevator Conveyor - Global Market:

When it comes to the materials used in the construction of Vertical Spiral Elevator Conveyors, carbon steel, stainless steel, and other materials each offer distinct advantages and are chosen based on specific application needs. Carbon steel is a popular choice due to its strength and durability, making it suitable for heavy-duty applications where the conveyor is subjected to significant wear and tear. It is also cost-effective, which makes it an attractive option for industries looking to balance performance with budget constraints. However, carbon steel is prone to rust and corrosion, which can be a drawback in environments where moisture or corrosive substances are present. On the other hand, stainless steel is highly resistant to corrosion and is often used in industries where hygiene and cleanliness are paramount, such as food processing and pharmaceuticals. Its ability to withstand harsh cleaning processes and resist contamination makes it ideal for applications where product purity is critical. Stainless steel conveyors are also known for their aesthetic appeal and long lifespan, although they come at a higher cost compared to carbon steel. In addition to these two primary materials, other materials such as aluminum and plastic are also used in the construction of Vertical Spiral Elevator Conveyors. Aluminum is lightweight and resistant to corrosion, making it suitable for applications where weight is a concern, and the environment is not overly harsh. Plastic, while not as strong as metal, offers excellent resistance to corrosion and is often used in applications where the conveyor will be exposed to chemicals or moisture. The choice of material ultimately depends on the specific requirements of the application, including the type of material being transported, the environmental conditions, and the desired lifespan of the conveyor. Each material offers unique benefits and trade-offs, and selecting the right one is crucial for ensuring the efficiency and longevity of the conveyor system.

Agriculture, Food, Achitechive, Others in the Vertical Spiral Elevator Conveyor - Global Market:

Vertical Spiral Elevator Conveyors are utilized in a variety of industries, each with its own unique requirements and challenges. In agriculture, these conveyors are used to transport grains, seeds, and other agricultural products vertically, allowing for efficient storage and processing. The ability to move large quantities of material quickly and with minimal spillage is particularly beneficial in this sector, where time and efficiency are critical. In the food industry, Vertical Spiral Elevator Conveyors are used to move products such as packaged foods, raw ingredients, and finished goods between different levels of a facility. Their compact design and ability to maintain product integrity make them ideal for food processing plants where space is limited, and hygiene is essential. In the architectural sector, these conveyors are used in the construction of buildings and other structures, where they help transport materials such as concrete, bricks, and other building supplies to different levels of a construction site. This not only improves efficiency but also enhances safety by reducing the need for manual handling of heavy materials. Beyond these specific industries, Vertical Spiral Elevator Conveyors are also used in a variety of other applications, including manufacturing, logistics, and warehousing. In these settings, they help streamline operations by providing a reliable and efficient means of moving products vertically, reducing the need for manual labor and improving overall productivity. The versatility and efficiency of Vertical Spiral Elevator Conveyors make them an invaluable tool in a wide range of industries, helping businesses optimize their operations and achieve their goals.

Vertical Spiral Elevator Conveyor - Global Market Outlook:

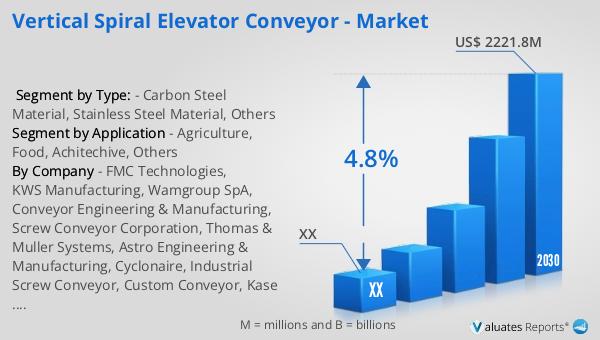

The global market for Vertical Spiral Elevator Conveyors was valued at approximately $1,609 million in 2023. This market is anticipated to grow steadily, reaching an estimated size of $2,221.8 million by the year 2030. This growth represents a compound annual growth rate (CAGR) of 4.8% over the forecast period from 2024 to 2030. This upward trend is indicative of the increasing demand for efficient and space-saving material handling solutions across various industries. As businesses continue to seek ways to improve operational efficiency and reduce costs, the adoption of Vertical Spiral Elevator Conveyors is expected to rise. These conveyors offer numerous advantages, including the ability to handle a wide range of materials, compact design, and high throughput rates, making them an attractive option for industries such as food processing, pharmaceuticals, and manufacturing. The projected growth in the market reflects the ongoing need for innovative and efficient material handling solutions that can meet the diverse needs of modern industries. As the market continues to expand, manufacturers and suppliers of Vertical Spiral Elevator Conveyors will need to focus on innovation and quality to meet the evolving demands of their customers and maintain a competitive edge in the market.

| Report Metric | Details |

| Report Name | Vertical Spiral Elevator Conveyor - Market |

| Forecasted market size in 2030 | US$ 2221.8 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | FMC Technologies, KWS Manufacturing, Wamgroup SpA, Conveyor Engineering & Manufacturing, Screw Conveyor Corporation, Thomas & Muller Systems, Astro Engineering & Manufacturing, Cyclonaire, Industrial Screw Conveyor, Custom Conveyor, Kase Custom Conveyors |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |