What is Global All Metal Robotic Arm Market?

The Global All Metal Robotic Arm Market refers to the worldwide industry focused on the production, distribution, and utilization of robotic arms made entirely of metal. These robotic arms are designed for various applications across multiple sectors, including industrial manufacturing, medical fields, military operations, semiconductor manufacturing, and the automotive industry. The market encompasses a wide range of robotic arms, from simple models with basic functionalities to highly sophisticated ones with advanced features. The use of metal in these robotic arms ensures durability, strength, and precision, making them suitable for tasks that require high levels of accuracy and reliability. The market is driven by the increasing demand for automation and the need for efficient and cost-effective solutions in various industries. As technology continues to advance, the capabilities of all-metal robotic arms are expected to expand, further driving their adoption across different sectors.

6 Axis, 7 Axis, Others in the Global All Metal Robotic Arm Market:

In the Global All Metal Robotic Arm Market, robotic arms are categorized based on the number of axes they possess, which determines their range of motion and flexibility. A 6-axis robotic arm, for instance, has six degrees of freedom, allowing it to move in six different directions. This type of robotic arm is highly versatile and can perform complex tasks such as welding, painting, and assembly with high precision. The six axes provide the arm with the ability to rotate and move in various directions, making it suitable for applications that require intricate movements and positioning. On the other hand, a 7-axis robotic arm offers an additional degree of freedom compared to the 6-axis model. This extra axis allows for even greater flexibility and maneuverability, enabling the arm to reach areas that would be difficult or impossible for a 6-axis arm to access. The 7-axis robotic arm is particularly useful in applications that require a high level of dexterity and precision, such as in medical surgeries or intricate assembly processes. Other types of robotic arms in the market may have fewer or more than six or seven axes, depending on the specific requirements of the application. For example, a 4-axis robotic arm may be used for simpler tasks that do not require as much flexibility, such as basic pick-and-place operations. Conversely, robotic arms with more than seven axes may be used in highly specialized applications that demand extreme precision and control. The choice of robotic arm depends on various factors, including the complexity of the task, the level of precision required, and the specific needs of the industry. In industrial manufacturing, for instance, 6-axis and 7-axis robotic arms are commonly used for tasks such as welding, painting, and assembly, where precision and flexibility are crucial. In the medical field, robotic arms with multiple axes are used in surgeries and other procedures that require high levels of accuracy and control. In the military, robotic arms are used for tasks such as bomb disposal and reconnaissance, where precision and reliability are essential. In semiconductor manufacturing, robotic arms are used for tasks such as wafer handling and assembly, where precision and cleanliness are critical. In the automotive industry, robotic arms are used for tasks such as welding, painting, and assembly, where speed and accuracy are important. Overall, the Global All Metal Robotic Arm Market offers a wide range of options to meet the diverse needs of various industries, with different types of robotic arms providing different levels of flexibility, precision, and control.

Industrial Manufacturing, Medical, Military, Semiconductor Manufacturing, Automotive Industry, Others in the Global All Metal Robotic Arm Market:

The Global All Metal Robotic Arm Market finds extensive usage across various sectors, each benefiting from the unique capabilities of these advanced machines. In industrial manufacturing, all-metal robotic arms are employed for tasks such as welding, painting, and assembly. Their precision and durability make them ideal for repetitive tasks that require consistent quality and efficiency. These robotic arms can operate in harsh environments and handle heavy loads, reducing the risk of injury to human workers and increasing overall productivity. In the medical field, robotic arms are used in surgeries and other procedures that demand high levels of accuracy and control. For instance, robotic-assisted surgeries allow for minimally invasive procedures, reducing recovery times and improving patient outcomes. These robotic arms can perform delicate tasks with precision, such as suturing or tissue manipulation, which would be challenging for human hands. In the military, all-metal robotic arms are utilized for tasks such as bomb disposal, reconnaissance, and equipment handling. Their robustness and reliability make them suitable for high-risk operations where human intervention would be dangerous. These robotic arms can be remotely controlled, allowing for safe and efficient execution of tasks in hazardous environments. In semiconductor manufacturing, robotic arms are used for wafer handling, assembly, and inspection. The precision and cleanliness required in this industry make all-metal robotic arms an ideal choice. They can handle delicate components with care, ensuring high-quality production and reducing the risk of contamination. In the automotive industry, robotic arms are employed for tasks such as welding, painting, and assembly. Their speed and accuracy contribute to efficient production lines, reducing manufacturing time and costs. These robotic arms can work continuously without fatigue, ensuring consistent quality and high output. Other sectors, such as aerospace, agriculture, and logistics, also benefit from the use of all-metal robotic arms. In aerospace, they are used for tasks such as component assembly and inspection, where precision and reliability are crucial. In agriculture, robotic arms are used for tasks such as planting, harvesting, and sorting, improving efficiency and reducing labor costs. In logistics, robotic arms are used for tasks such as sorting and packaging, streamlining operations and increasing throughput. Overall, the Global All Metal Robotic Arm Market offers versatile solutions for a wide range of applications, enhancing efficiency, precision, and safety across various industries.

Global All Metal Robotic Arm Market Outlook:

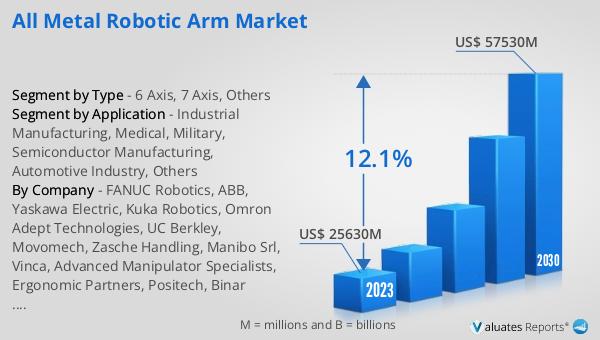

The global All Metal Robotic Arm market was valued at US$ 25,630 million in 2023 and is anticipated to reach US$ 57,530 million by 2030, witnessing a CAGR of 12.1% during the forecast period 2024-2030. This significant growth reflects the increasing demand for automation and advanced robotic solutions across various industries. The market's expansion is driven by the need for efficient, reliable, and precise robotic arms that can perform complex tasks with high accuracy. The use of all-metal construction ensures durability and strength, making these robotic arms suitable for a wide range of applications, from industrial manufacturing to medical procedures. As industries continue to seek ways to improve productivity and reduce costs, the adoption of all-metal robotic arms is expected to rise. The market's growth is also supported by advancements in technology, which are enhancing the capabilities and functionalities of these robotic arms. With the increasing focus on automation and the benefits it offers, the Global All Metal Robotic Arm Market is poised for substantial growth in the coming years.

| Report Metric | Details |

| Report Name | All Metal Robotic Arm Market |

| Accounted market size in 2023 | US$ 25630 million |

| Forecasted market size in 2030 | US$ 57530 million |

| CAGR | 12.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | FANUC Robotics, ABB, Yaskawa Electric, Kuka Robotics, Omron Adept Technologies, UC Berkley, Movomech, Zasche Handling, Manibo Srl, Vinca, Advanced Manipulator Specialists, Ergonomic Partners, Positech, Binar Handling, Lissmac, Indeva, GCI, Givens Engineering, Ergoflex, HUSCH, Famatec, ATIS Srl, Dalmec, Unidex |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |